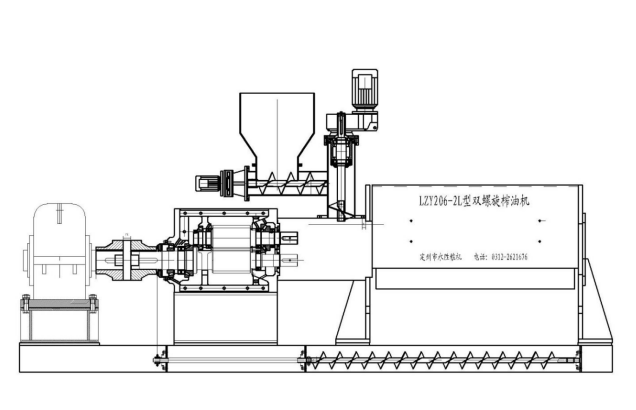

LZY-206 Double Screw Cold Oil Press

The machine USES and features:

This machine USES suitable for plant extract oil, it is not only suitable for high temperature steaming and frying oil press (hot press) but also suitable for room temperature without steaming and frying oil press (cold pressed).

At the same time also can suitable for cold pressing of oil; Especially suitable for oil seed peeling after shelling or room temperature and low temperature crushing, such as: camellia seed, tea seed, corn germ, rapeseed, canopy seed, safflower, peony seed, special oil such as peanut kernels, cottonseed kernels, flax seed, rubber seed, fire is pitted and prickly ash seed room temperature or cold pressing.

main feature:

(1)A new double spiral oil press compared with single screw press, used more widely.

Squeeze in the same cage, unique double helix structure, not only is this machine has the fine crushing process characteristics, and has a strong axial boost, not even oil after peeling (shell) in crash phenomenon.

(2)This machine is suitable for pressing oil. Apply hot pressing, cold pressing and cold pressing.

(3)The native novel principle, reasonable structure, stable running, good mechanical performance. The mechanical transmission system main components such as biaxial squeezed oil gear box, the double helix of the institutions and the agencies in cake gear shaft, shaft, squeezer, pressing sha-lu, stern and bread first adopt high quality alloy steel, and the strict heat treatment, so the machine Durable.

(4)This machine use the operating is similar with single screw press, the feeding device of the horizontal screw conveyor grinding cage adopts frequency control of motor speed control, so the material flow evenly, easy to control, easy to operate.

Composition and structure

1.Composition

2 l double spiral oil press is shown in figure 1.

This machine is mainly composed of main motor and mechanical transmission system, biaxial gear box, feeding device, cage, the out-feeding in cake, residue and oil tank, frame and electrical control system.

2.Structure

(1)2 l double spiral oil press mechanical drive system is mainly composed of motor and "V" belt and pulley, cylindrical gear reducer, coupling, etc.

(2)Two axle gear box is mainly composed of box body, the first and second gear shaft and thrust self-aligning roller bearings, double row needle roller bearing, tapered roller bearings, end cover, round nut, locking gasket and seal rings etc.

(3)Feeding device is mainly composed of cycloidal pinwheel reducer, horizontal grinding cage with motor, vertical grinding cage and hopper and ram, etc.

(4)Double helix axis is mainly composed of core shaft, section 9 squeezer (18), 6 press circle (a total of 12) and keep-off ring, etc; Two vats screw on the screw shaft are left-handed and a right-handed respectively

(5)Pressing cage is mainly composed of pressing cage body, pressure plate, special-shaped weight up and down, pressing bar and tighten bolts and nuts, etc.

(6)The out-feeding in cake is mainly composed of a pie plate, stern, for cake head, thrust ball bearings, roller and the supporting shaft, adjusting bolt and nut and beams, etc, can freely adjust the cake thickness, advance and retreat freely, a great innovation in the double helix.

(7)Residue and fuel tank is mainly composed of oil storage tank, the sieve plate and frame, etc.

(8)Rack is mainly composed of base, gear box pad high seat, reducer, pressing cage of left and right wall plate and connecting bolts, etc.

(9)Electrical control system controlled by the main motor control box, vertical grinding cage motor drive level grinding cage drive motor frequency control of motor speed control, etc

The main technical parameters see below:

|

Model |

L--126 |

L--206 |

|

(capacity per day)Ton/24hous |

4—10 |

20—40 |

|

(speed of spindle) r/min |

10—16 |

10—16 |

|

Main power(KW) |

15 |

45 |

|

(Round speed of vertical pressing shaft)r/min |

60—80 |

60—80 |

|

(Vertical swage power)KW |

1.1 |

3.0 |

|

(horizontal scraper power)KW |

0.75 (frequency control)

|

1.5 (frequency control)

|

|

overall dimension (mm) |

3300x1700x1500 |

4365x2300x1500 |