Crude Cooking Oil Refining Unit

Basic Info.

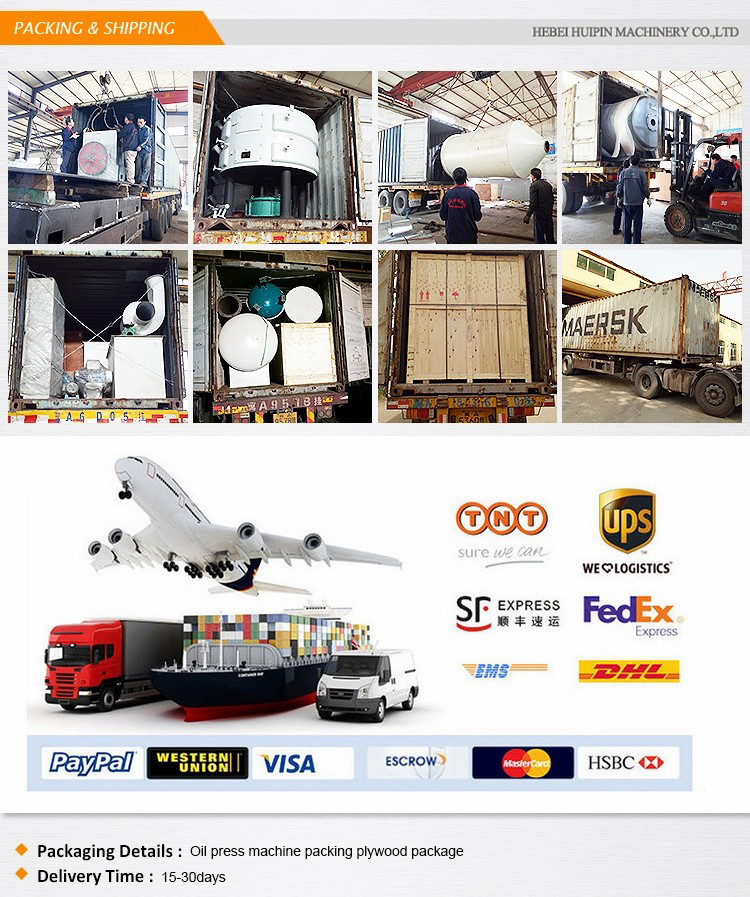

| Model NO. | HP | Condition | New |

| Customized | Customized | Trademark | HUIPIN |

| Transport Package | Plastic Film | Specification | 2000*2000*2750 |

| Origin | China | HS Code | 847920 |

Our company has developed various types of oil press and physical crushing of vegetable oil with foreign advanced technology, which not only ensures the processing accuracy and efficiency of oil press, but also ensures the quality of oil press and oil production line. Our factory can undertake 1 ton to 1000 tons per 24 hours sunflower seed oil, peanut oil, rapeseed oil, soybean oil, cottonseed oil, corn germ oil, coconut oil, safflower seed oil, palm oil, cashew nut shell oil, animal oil and other oil physical pressing refining production lines.

The main purpose of refining is to purify oil and remove impurities by degumming and deacidification, so as to obtain pure and relatively impurity free high-quality edible oil.

Below are the refining steps:

1. Crude oil refinery equipment includes a series processing procedures as degumming, neutralization, bleaching, deodorization and winterisation.

2. In general there are two methods of vegetable/edible oil processing, one is physical refining and the other is chemical refining.

3. However, no matter what kinds of reining methods, they are all done with the help of various oil processing equipment and machinery, and are used to refine almost all kinds of oil extracted from oil seeds like sunflower seeds, peanuts , sesame seeds, and soya bean seeds, palm ,cottonseed , ect.The main equipment of oil refinery is various kinds of pot and tanks carrying on different tasks with additives. These tasks may include sedimentation/filtering, neutralization (removing free fatty acid), degumming, decolorization (bleaching), deodorization, dewax etc. Different combination of steps and the treating degree of each step result in different grade cooking oil and salad oil.

Main process of oil refinery equipment

Degumming:The purpose of Degumming Vegetable Oils is to remove Gums. All oils have hydratable and non-hydratable gums.

a. Water Degumming: Hydratable gums are removed by treating oils with water and separating the gums. The gums can be dried to produce lecithin.

b. Acid Degumming: Non-Hydratable gums are removed by treating oils with acids and separating the gums.

Neutralizing: The purpose of Neutralizing Vegetable Oils is to remove Free-Fatty Acids (FFAs). Traditionally, FFAs are treated with caustic soda (NaOH). The reaction produces Soaps which are separated from the oil. Because trace amounts of soaps remain in the oil, the oil is either washed with water or treated with Silica.

Some processors prefer not to perform caustic neutralizing. Instead, they prefer Physical Refining in which the FFAs are evaporated from the oil under high temperature and vacuum. This process can be combined with deodorization step described under FFA stripping.

Physical Refining process is preferred because (a) it does not produce soaps; (b) it recovers fatty acids that provide better cost recovery; (c) there is smaller yield loss compared to caustic refining-especially for oils with higher FFAs; and (d) it is a chemical-free process.

Bleaching:The purpose of Bleaching is to remove color pigments contained in Vegetable Oils. The oil is treated with Bleaching Clays that adsorb the color pigments. The clay is filtered and the clean bleached oil is stored for further processing. Process flow diagram is attached.

Deodorizing:The purpose of Deodorizing Vegetable Oils is to remove odor substances. The oil is subjected to steam distillation under high temperature and vacuum to evaporate all odor substances. The resulting deodorized oil is almost bland and tasteless