aug . 13, 2025 14:45 Tilbake til listen

Precision Processing for Pure Results

In the modern edible oil industry, refining is more than a step—it's a transformation. As consumers become more quality-conscious and regulatory standards grow increasingly stringent, producers need reliable technology to purify crude oils into safe, shelf-stable, and appealing final products. This is where the importance of a robust Crude Oil Refining Machine or an integrated Crude Oil Refining Unit becomes evident. From removing impurities and odors to stabilizing flavor and color, oil refining is a crucial process for converting raw oil into a market-ready commodity. Whether working with rapeseed, soybean, sunflower seed, or other oil-bearing crops, effective refining ensures product consistency and value. High-performance systems like the Rapeseed Oil Refining Unit and Soyaoljeraffineringsenhet deliver results that meet industry demands for purity, safety, and scalability.

Transforming Raw Oil into Refined Quality with Modern Machinery

Raw vegetable oil, in its unprocessed form, contains various impurities such as phospholipids, free fatty acids, pigments, and waxes that affect its taste, color, and shelf life. The Crude Oil Refining Machine addresses these challenges by incorporating a sequence of carefully controlled operations, including degumming, neutralization, decolorization, deodorization, and dewaxing. These mechanical and chemical processes work in tandem to enhance the oil’s clarity, flavor, and nutritional value.

Through advanced engineering, today's refining machines feature improved thermal control, enhanced mixing systems, and automated process monitoring, ensuring each batch of oil meets strict food safety and quality standards. Whether applied in a small-scale startup or a large-scale industrial refinery, the Crude Oil Refining Machine adapts to different throughput capacities while maintaining consistency in output. This versatility is essential in a global market that values both quality and efficiency.

Modular Refining Solutions for Scalable Oil Production

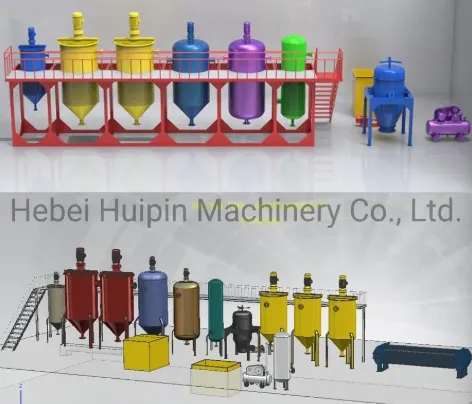

An integrated Crude Oil Refining Unit is more than a single piece of equipment—it is a structured system designed to accommodate the complete refining workflow. Unlike stand-alone machines, a unit brings together multiple tanks, reactors, heat exchangers, and filters, enabling a continuous process from crude oil intake to final product storage. The modular design allows producers to scale operations depending on demand, whether refining hundreds of liters per day or managing large industrial volumes.

Each Crude Oil Refining Unit can be customized to fit different oil types and refining techniques, including physical refining (which focuses on steam distillation and minimal chemical use) or chemical refining (which utilizes alkali neutralization to remove free fatty acids). Regardless of the method, the goal remains the same: to produce a high-quality edible oil that is free from unwanted substances. These refining units also support efficient heat recovery and low energy consumption, making them a sustainable investment for companies looking to reduce operational costs and environmental impact.

Specialized Refining for High-Value Rapeseed Oil

Rapeseed oil is increasingly favored for its favorable fatty acid composition and light flavor, but refining it requires particular care due to its sensitivity to heat and oxidation. The Rapeseed Oil Refining Unit is engineered with this in mind, offering precision control over every stage of the process to ensure that valuable nutrients and natural antioxidants are preserved. From initial degumming, which removes hydratable phospholipids, to deodorization, which eliminates volatile odor compounds, each stage is optimized to handle rapeseed’s unique characteristics.

In addition, the Rapeseed Oil Refining Unit incorporates dewaxing functions to prevent haziness in the finished oil, especially when stored at lower temperatures. This makes the oil suitable for both household and commercial use, including in salad dressings, frying oils, and margarine. By ensuring clarity, stability, and a mild aroma, the refining unit helps producers maintain the quality that consumers expect in premium edible oils.

Efficient Soybean Oil Purification for Mass Markets

Soybean oil is one of the most widely consumed edible oils globally, making consistency and purity essential in large-scale production. The Soyaoljeraffineringsenhet is specifically designed to address the typical impurities found in crude soybean oil, such as gums, pigments, peroxides, and unpleasant odors. With a high degree of automation and advanced material handling, this unit allows for uninterrupted processing with minimal manual intervention, reducing labor costs and improving safety.

What sets the Soyaoljeraffineringsenhet apart is its ability to stabilize oil quality while maximizing yield. Even small variations in degumming or deodorization can affect flavor and shelf life, but with precise temperature and vacuum controls, this refining system ensures a uniform output every time. Furthermore, the unit is compatible with both batch and continuous refining systems, offering flexibility to match market requirements. For large processors aiming to meet stringent food-grade standards without compromising efficiency, this unit delivers a dependable and scalable solution.

Crude Oil Refining Unit FAQs

What is the main purpose of a crude oil refining machine?

The Crude Oil Refining Machine is used to remove impurities such as phospholipids, free fatty acids, waxes, pigments, and odorous compounds from crude vegetable oils. This process enhances the oil’s clarity, flavor, stability, and shelf life, making it suitable for human consumption and commercial sale. The machine enables producers to meet food safety standards and consumer expectations for purity.

What are the key differences between physical and chemical refining?

Physical refining uses steam distillation to remove free fatty acids and relies less on chemical additives, making it suitable for certain oils like palm oil. Chemical refining involves treating the crude oil with alkali to neutralize free fatty acids and then removing soaps and other by-products. Both methods can be used in a Crude Oil Refining Unit, depending on the oil type and desired quality specifications.

How does the rapeseed oil refining process differ from others?

Rapeseed oil contains higher levels of phospholipids and waxes, requiring more precise degumming and dewaxing stages. The Rapeseed Oil Refining Unit includes specially calibrated controls to prevent oxidation and nutrient loss during deodorization, ensuring a clear, stable oil with a mild flavor. These tailored steps help maintain the oil’s market appeal in both foodservice and retail applications.

Is the soybean oil refining process energy efficient?

Yes, the Soyaoljeraffineringsenhet is designed with energy-saving components such as heat exchangers and vacuum systems that recover and reuse thermal energy. Automated controls ensure that only the necessary amount of energy is used at each stage, minimizing waste while maintaining product quality. This makes soybean oil refining both cost-effective and environmentally responsible.

Can crude oil refining equipment be customized for small-scale producers?

Absolutely. Both Crude Oil Refining Machine and Crude Oil Refining Unit systems can be customized in size, configuration, and degree of automation to suit small-scale operations. Many suppliers offer modular systems that start small and can be expanded as production needs grow. These solutions make it feasible for local producers, cooperatives, and entrepreneurs to enter the edible oil market with professional-grade output.

-

The Power of Modern Oil Press Technologies

NyheterAug.13,2025

-

The Power of an Advanced Oil Press Machine

NyheterAug.13,2025

-

Precision Processing for Pure Results

NyheterAug.13,2025

-

Maximizing Oilseed Processing Efficiency with Advanced Cottonseed Sheller Technology

NyheterAug.13,2025

-

High-Efficiency Oilseed Press Machines for Modern Production

NyheterAug.13,2025

-

Comprehensive Vegetable Oil Refining Solutions

NyheterAug.13,2025