Jul . 18, 2025 10:03 Back to list

Unveiling the Technology Behind Seed Oil Refining Machinery

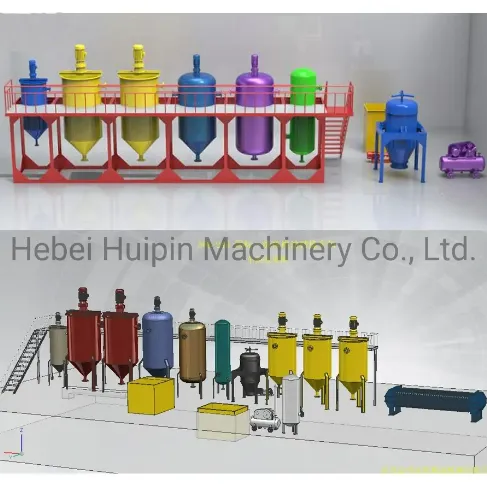

In the realm of edible oil production, refining machines play a pivotal role in transforming crude oils into high - quality, safe, and shelf - stable products. Among the key equipment used in this process are specialized refining machines designed for different oils, including Rapeseed Oil Refining Machine, Soybean Oil Refining Machine, Seed Oil Refining Machine, Mustard Oil Refining Machine, and Corn Germ Oil Refining Machine. Each of these machines is engineered to address the unique characteristics of the oil it processes, ensuring optimal removal of impurities, toxins, and unwanted compounds while preserving the oil’s nutritional value and sensory qualities.

Exploring the Functionality of Rapeseed Oil Refining Machine

A Rapeseed Oil Refining Machine is tailored to handle rapeseed oil, which often contains high levels of erucic acid and glucosinolates. The refining process typically involves several stages: degumming to remove phospholipids, neutralization to eliminate free fatty acids, (decolorization) to remove pigments, and deodorization to eliminate unpleasant odors. For instance, in large - scale rapeseed oil production facilities, the Rapeseed Oil Refining Machine efficiently processes crude oil by first subjecting it to degumming with water or acid, followed by neutralization with caustic soda. The machine’s design ensures that erucic acid levels are reduced to meet food safety standards, resulting in a refined oil that is suitable for various culinary and industrial applications.

Delving into Soybean Oil Refining Machine Operations

The Soybean Oil Refining Machine is designed to process soybean oil, one of the most widely consumed vegetable oils globally. Soybean oil often contains impurities such as phosphatides, sterols, and tocopherols, which need to be carefully removed or stabilized during refining. The machine typically incorporates steps like solvent extraction for oil recovery, followed by degumming, neutralization,and deodorization. In commercial settings, the Soybean Oil Refining Machine can handle large volumes of crude soybean oil, ensuring that the final product is free from harmful substances while retaining beneficial components like vitamin E. The machine’s efficiency is crucial in meeting the high demand for soybean oil in food industries, such as for frying, salad dressings, and margarine production.

Examining the Versatility of Seed Oil Refining Machine

A Seed Oil Refining Machine is a more generalized solution capable of processing various types of seed - based oils, including sunflower, sesame, and cottonseed oil. These machines are designed with adjustable parameters to accommodate the different physical and chemical properties of various seed oils. For example, when processing sunflower oil, the Seed Oil Refining Machine might focus on removing waxes through winterization, while for sesame oil, it could emphasize deodorization to retain the oil’s distinct aroma. The machine’s modular design allows for easy adaptation to different refining processes, making it a cost - effective choice for producers dealing with multiple oil types. Its ability to handle both high - and low - acid oils ensures versatility in meeting diverse market requirements.

Analyzing the Specifics of Mustard Oil Refining Machine

Mustard Oil Refining Machine is designed to process mustard oil, which is known for its pungent flavor and high content of glucosinolates and volatile compounds. The refining process for mustard oil often involves a combination of physical and chemical methods. In some regions, traditional mustard oil is minimally refined to retain its characteristic flavor, but for commercial purposes, the Mustard Oil Refining Machine may include steps like degumming to remove mucilaginous substances, neutralization to reduce free fatty acids, and deodorization to moderate the pungency while eliminating harmful compounds. The machine’s design ensures that the refined mustard oil is safe for consumption, with a balanced flavor profile that appeals to a wide range of consumers, particularly in cuisines where mustard oil is a staple.

Understanding Corn Germ Oil Refining Machine Features

Corn Germ Oil Refining Machine is specialized for processing corn germ oil, which is extracted from the germ of corn and is rich in nutrients like (oryzanol) and vitamin E. The refining process for corn germ oil focuses on preserving these beneficial components while removing impurities such as waxes, pigments, and odoriferous substances. The machine typically includes stages like degumming, alkali refining, with activated clay, and deodorization under vacuum to prevent thermal degradation of nutrients. In food production, the Corn Germ Oil Refining Machine ensures that the final oil has a light color, neutral taste, and high oxidative stability, making it suitable for high - temperature cooking and as a healthy cooking oil option.

FAQ: Key Insights into Seed Oil Refining Machines

How to select the appropriate refining machine for a specific oil type?

Choosing the right machine depends on the oil’s unique properties, such as acid content, impurity types, and desired end - product specifications. For example, a Rapeseed Oil Refining Machine is ideal for oils high in erucic acid, while a Corn Germ Oil Refining Machine is designed to preserve the nutritional components of corn germ oil. Assess the machine’s processing capacity, energy efficiency, and the stages it includes (e.g., degumming, deodorization) to ensure it aligns with your production needs.

What maintenance practices ensure the longevity of refining machines?

Regular maintenance is crucial for optimal performance. This includes cleaning the machine’s components to prevent residue buildup, inspecting filters and valves for clogs or damage, and lubricating moving parts as per the manufacturer’s guidelines. For Soybean Oil Refining Machine or Mustard Oil Refining Machine, paying attention to the condition of media (such as activated carbon or clay) and replacing them when their adsorption capacity is exhausted is essential for maintaining refining efficiency.

Can these refining machines handle both small - scale and large - scale production?

Many refining machines, including Seed Oil Refining Machine and specialized types, are available in various capacities. Small - scale models are suitable for artisanal producers or pilot plants, while large - scale industrial machines can process thousands of liters per hour. Manufacturers often offer customizable solutions, allowing producers to scale their operations without compromising on refining quality.

What factors influence the energy consumption of oil refining machines?

Energy consumption depends on factors such as the machine’s size, the number of refining stages, and the type of energy used (e.g., electricity, steam). For instance, deodorization in a Corn Germ Oil Refining Machine requires high - temperature processing, which can increase energy use. Modern machines are designed with energy - efficient components, such as heat recovery systems, to minimize consumption while maintaining high - quality refining results.

Are there differences in refining processes between cold - pressed and solvent - extracted oils?

Yes, the refining process can vary based on the oil extraction method. Cold - pressed oils often have fewer impurities but may require gentle refining to preserve their natural characteristics, while solvent - extracted oils typically need more rigorous processing to remove solvent residues and other contaminants. A Seed Oil Refining Machine can be adjusted to handle both types, with parameters modified to suit the specific challenges posed by each extraction method.

Ichi ndicho chinyorwa chekupedzisira

-

Unveiling the Technology Behind Seed Oil Refining Machinery

NewsJul.18,2025

-

Unveiling the Mechanics and Applications of Oil Refining Machinery

NewsJul.18,2025

-

Unveiling the Essence of Refined Oil Units in Food Processing

NewsJul.18,2025

-

Exploring the Technology and Applications of Oil Refining Machinery

NewsJul.18,2025

-

Exploring the Mechanics and Applications of Centrifuge Technology

NewsJul.18,2025

-

Exploring the Efficiency and Design of Seed Oil Refined Units

NewsJul.18,2025