Авг . 28, 2025 01:20 Обратно к списку

Efficient Black Seed Oil Expeller | High Yield Oil Press Machine

Industry Trends in Cold Press Oil Extraction

The global market for natural and health-oriented products continues its robust expansion, driving significant demand for high-quality, cold-pressed oils. Consumers and industries alike are increasingly prioritizing minimal processing to preserve nutritional integrity and functional benefits. This paradigm shift has amplified the criticality of efficient and reliable extraction technologies. Specifically, the market for specialty oils such as black seed oil, flaxseed oil, and linseed oil has seen a surge, propelled by their documented health benefits and diverse applications in nutraceuticals, pharmaceuticals, and cosmetics.

Manufacturers are constantly seeking advanced solutions to optimize oil yield, maintain product purity, and ensure operational sustainability. This includes refining processes that extend beyond mere pressing, integrating sophisticated units like a установка по переработке льняного масла or a complete линия по переработке льняного масла to meet stringent quality standards. The evolution of oil mill machinery, including the машина для производства льняного масла and the машина для производства льняного масла, reflects this demand for versatility and efficiency across various oilseeds, including the high-value Отгонитель масла черного тмина. Furthermore, the capacity to process challenging materials like palm kernel with a dedicated машина для прессования пальмовых ядер is becoming a key differentiator in the competitive landscape.

Technological advancements focus on enhancing extraction efficiency, reducing energy consumption, and improving the overall quality of the extracted oil. This includes innovations in screw press design, temperature control, and material science, all contributing to a more sustainable and economically viable oil production process. The emphasis is on equipment that delivers high purity and preserves the delicate compounds within the oil, critical for premium market segments.

Process Flow: Manufacturing of a High-Performance Black Seed Oil Expeller

The manufacturing of a high-performance Отгонитель масла черного тмина is a multi-stage process, meticulously designed to ensure durability, efficiency, and food-grade safety. Each step, from material selection to final assembly, adheres to stringent engineering and quality control protocols.

Key Manufacturing Steps:

- Material Selection and Preparation: High-grade stainless steel (e.g., SUS304 or SUS316 for food contact parts) and specialized alloy steels (e.g., 40Cr, 45# steel for screw shafts and pressing cages) are selected for their corrosion resistance, hardness, and wear resistance. Raw materials undergo rigorous quality checks for chemical composition and mechanical properties, ensuring compliance with ISO standards.

- Casting and Forging: Major structural components, such as the main frame and gearbox casings, are typically produced via precision casting. Critical stress components like the screw shaft and pressing worms are forged from high-strength alloy steels. Forging refines the grain structure, enhancing fatigue resistance and overall strength, crucial for the continuous high-pressure operation of a Отгонитель масла черного тмина.

- CNC Machining: Advanced Computer Numerical Control (CNC) machining centers are utilized for precise shaping and finishing of all components. This ensures tight tolerances for screw pitch, bore alignment, and surface finishes, which directly impact oil yield and operational smoothness. Precision machining is vital for achieving the optimal clearance between the pressing screw and cage, minimizing friction and maximizing extraction efficiency.

- Heat Treatment: Components subjected to high wear and stress, particularly the screw shaft, pressing rings, and expeller worms, undergo specialized heat treatment processes (e.g., quenching, tempering, carburizing). This dramatically increases their surface hardness and wear resistance, extending the service life of the machine by ensuring components can withstand abrasive forces from oilseeds.

- Surface Finishing and Polishing: Food-contact surfaces are polished to a high standard to prevent adhesion of oil residues and facilitate easy cleaning, meeting stringent hygienic requirements. Non-food contact parts receive protective coatings to enhance corrosion resistance and aesthetic appeal.

- Assembly and Integration: Components are meticulously assembled. Bearings, gears, and electrical systems are integrated. Critical alignments are verified using laser alignment tools to ensure smooth, vibration-free operation and minimize wear on moving parts.

- Quality Assurance and Testing: Each Отгонитель масла черного тмина undergoes rigorous testing protocols. This includes pressure tests, leakage tests, full load operational tests, and noise level assessments. Key performance indicators such as oil yield, residue oil content, and energy consumption are validated against design specifications and international standards like ISO 9001 for quality management and relevant ANSI/CE directives for safety and performance.

Service Life and Target Industries:

With proper maintenance, a well-manufactured Отгонитель масла черного тмина can achieve a service life of 15-20 years or more. Its robust construction ensures sustained performance in demanding environments. Target industries include: Food & Beverage (edible oils, health supplements), Pharmaceutical (API extraction), Cosmetics (natural ingredients for skincare), and specialty Chemical applications. The inherent advantages include significant energy saving due to optimized screw designs, and superior corrosion resistance from high-grade materials, crucial for processing diverse oilseeds.

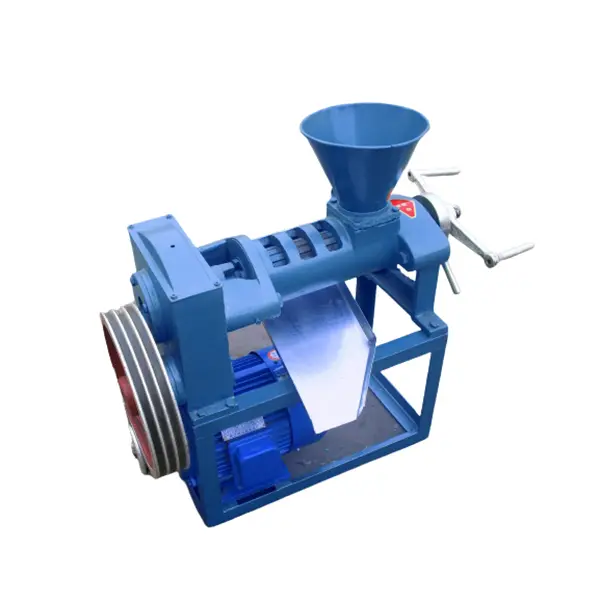

Technical Specifications and Parameters: HP120 Small Capacity Cold Oil Press

Understanding the precise technical specifications of an oil expeller is paramount for B2B decision-makers. The HP120 Small Capacity Cold Oil Press exemplifies a compact yet powerful solution for efficient oil extraction, particularly suited for high-value seeds like black seed. Its design prioritizes cold pressing to preserve the delicate nutrients and flavors of the oil, distinguishing it from traditional hot pressing methods.

HP120 Product Specification Table:

| Parameter | Спецификация |

|---|---|

| Model Name | Пресс для холодного масла малой мощности HP120 |

| Processing Capacity | 5-15 kg/hour (dependent on seed type, e.g., 8-10 kg/h for black seed) |

| Motor Power | 1.5 kW (standard, 220V/380V options available) |

| Oil Yield Rate | 40-55% for black seed (varies by seed type and moisture content) |

| Residual Oil in Cake | < 7% (optimized for minimal waste) |

| Pressing Method | Cold Pressing (Max. 60°C extraction temperature) |

| Materials of Construction | Food-grade SUS304 stainless steel for contact parts; high-strength alloy steel for screw & pressing cage. |

| Dimensions (L x W x H) | Approx. 700 x 300 x 600 mm |

| Масса | Approx. 55 kg |

| Heating System | Integrated intelligent temperature control for pre-heating and stable operation. |

| Certifications | CE, ISO 9001 |

The HP120's robust construction with food-grade stainless steel ensures both hygiene and longevity, crucial for applications involving edible oils. Its compact design and user-friendly interface make it an ideal choice for businesses requiring flexible and efficient small-scale oil production, including various types of пресс для льняного масла and пресс для льняного масла operations.

Application Scenarios for Black Seed Oil Expeller

The versatility and nutritional benefits of black seed oil, extracted via a dedicated Отгонитель масла черного тмина, open up a multitude of application scenarios across various industries. These scenarios highlight the critical role of efficient and hygienic extraction technology in delivering high-quality products to the market.

- Nutraceutical and Health Supplement Manufacturing: Black seed oil is highly prized for its rich content of thymoquinone, a powerful antioxidant and anti-inflammatory compound. Expellers are used to extract virgin, cold-pressed oil, which is then encapsulated or bottled as a dietary supplement. Purity and nutrient preservation are paramount in this sector, making cold press technology indispensable.

- Pharmaceutical Active Pharmaceutical Ingredient (API) Production: For pharmaceutical applications, the extracted black seed oil can serve as a base or an active ingredient in various formulations. Precision expellers ensure consistent oil quality and yield, critical for batch-to-batch uniformity required in drug manufacturing.

- Cosmetic and Personal Care Industry: Black seed oil is a valued ingredient in skincare, haircare, and anti-aging products due to its moisturizing, antioxidant, and regenerative properties. Manufacturers utilize expellers to produce pure oil for serums, creams, and balms, ensuring natural product integrity.

- Gourmet Food and Culinary Applications: While primarily known for its health benefits, black seed oil also has a distinct, pungent flavor that can be used in gourmet dressings, marinades, and as a finishing oil. Small-scale producers and specialty food companies leverage expellers for fresh, on-demand production.

- Small-Scale Farming and Agricultural Cooperatives: Farmers' cooperatives and small businesses focused on organic and natural products can utilize compact Отгонитель масла черного тмина units to add value to their crops. This enables them to produce their own branded oils, catering directly to consumers or local markets with fresh, unadulterated products. The same machinery can often process other seeds like those requiring a пресс для льняного масла.

- Research and Development Facilities: Academic institutions and corporate R&D departments use these expellers for pilot-scale extraction of various specialty oils, including средство для вытеснения льняного масла trials, to study oil composition, optimize extraction parameters, and develop new product formulations.

In all these scenarios, the ability of a modern Отгонитель масла черного тмина to achieve high oil yield while maintaining the integrity of sensitive compounds is a critical advantage, ensuring product efficacy and market competitiveness.

Technical Advantages of Advanced Oil Expellers

Modern oil expellers, particularly those designed for cold pressing, offer significant technical advantages that translate into superior product quality, operational efficiency, and long-term cost savings for businesses. These advantages are crucial for processing valuable oilseeds like black seed, flaxseed, and linseed.

- High Oil Yield with Low Residual Oil: Advanced expeller designs incorporate optimized screw configurations and precision-engineered pressing cages. This allows for maximum oil extraction, often achieving residual oil content in the cake below 7%. This efficiency directly impacts profitability, especially for high-value seeds.

- Superior Nutrient and Flavor Preservation (Cold Pressing): Unlike hot pressing, cold pressing maintains a lower processing temperature (typically below 60°C). This preserves the heat-sensitive vitamins, antioxidants, fatty acids (e.g., Omega-3s in flaxseed), and volatile aromatic compounds, resulting in a healthier, more flavorful, and organoleptically superior oil.

- Robust Durability and Extended Service Life: Constructed from high-strength, wear-resistant materials such as hardened alloy steels for screw shafts and food-grade stainless steel for critical contact parts, these machines are built for continuous operation. Components undergo specialized heat treatments, significantly extending their operational lifespan and reducing the frequency of replacements.

- Energy Efficiency and Cost Savings: Modern expellers feature optimized motor systems and low-friction designs, reducing power consumption per liter of oil produced. Integrated intelligent temperature control systems ensure stable operation without excessive energy use, contributing to lower operating costs.

- Ease of Operation and Maintenance: User-friendly interfaces, often with intuitive controls, simplify operation. Quick-disassembly designs for pressing cages and screws facilitate easy cleaning and routine maintenance, minimizing downtime and ensuring hygienic operation, which is critical for a машина для производства льняного масла or машина для производства льняного масла.

- Versatility Across Seed Types: While optimized for Отгонитель масла черного тмина applications, many units are adaptable to process a wide range of oilseeds including flaxseed, linseed, sunflower, sesame, and even smaller palm kernel batches with appropriate adjustments, making them a versatile investment.

- Compliance with Industry Standards: Reputable manufacturers ensure their expellers comply with international standards such as CE for electrical safety and ISO for quality management, providing assurance of reliability and safety.

These technical advantages collectively ensure that a high-quality Отгонитель масла черного тмина is not just an expense, but a strategic investment that delivers tangible returns through superior product output and operational longevity.

Vendor Comparison: Selecting the Right Black Seed Oil Expeller Partner

Choosing the right vendor for a Отгонитель масла черного тмина is a strategic decision that impacts operational efficiency, product quality, and long-term profitability. A thorough comparison requires evaluating not just the equipment itself, but also the vendor's reputation, support infrastructure, and commitment to innovation. Here’s a comparative analysis of key factors:

Expeller Vendor Comparison Table:

| Feature/Criterion | Premium Vendor (e.g., OilMillChina) | Standard Vendor | Budget Vendor |

|---|---|---|---|

| Oil Yield Rate (Black Seed) | High (40-55%), consistent via optimized screw design. | Medium (35-45%), can vary. | Lower (30-40%), significant losses. |

| Residual Oil in Cake | < 7%, industry leading. | 8-12%, moderate efficiency. | > 12%, considerable waste. |

| Material Quality (Food Contact) | SUS304/316 Stainless Steel, certified. | Lower grade stainless steel or plated parts. | Non-food grade, prone to corrosion. |

| Manufacturing & Testing Standards | ISO 9001, CE, stringent internal QC. | Basic CE, limited internal testing. | Minimal or no certifications. |

| After-Sales Support & Warranty | Comprehensive (1-2 year warranty, 24/7 tech support, spare parts availability, training). | Limited (6-12 month warranty, basic support during business hours). | Very limited or non-existent support. |

| Customization Options | Extensive (capacity, material, automation, integration with линия по переработке льняного масла). | Basic modifications. | None. |

| Price Point | Premium (Reflects quality, performance, and support). | Mid-range. | Low (Often compromises quality and longevity). |

Investing in a premium Отгонитель масла черного тмина from a reputable vendor translates to higher yields, purer oil, longer equipment lifespan, and reliable operational support. This minimizes hidden costs associated with downtime, maintenance, and product quality issues, making it a more economical choice in the long run for discerning B2B clients.

Customized Solutions for Oil Extraction

Recognizing that no two businesses are identical, leading manufacturers offer customized solutions for oil extraction, extending beyond standard Отгонитель масла черного тмина models. These tailored approaches ensure that the equipment seamlessly integrates with existing operations and meets specific processing requirements, maximizing efficiency and return on investment.

- Capacity Scaling: Solutions range from small-capacity units like the HP120 for startups and R&D to industrial-scale expellers capable of processing tons of raw material per day. Customization includes engineering the motor power, screw diameter, and barrel length to match desired output.

- Material Specifications: For clients with stringent hygiene requirements (e.g., pharmaceutical or infant food industries), options for higher grades of stainless steel (e.g., 316L) for all contact parts are available. Specialized coatings can also be applied for abrasive or corrosive seed types.

- Automation and Control Integration: Customized control panels, PLC (Programmable Logic Controller) integration for automated start/stop, temperature regulation, and fault detection are offered. This allows for remote monitoring and integration into larger manufacturing execution systems (MES).

- Ancillary Equipment Integration: Beyond the expeller itself, comprehensive solutions often include integration with pre-treatment equipment (seed cleaners, roasters if hot pressing is required), filtration units, oil storage tanks, and even a full установка по переработке льняного масла or линия по переработке льняного масла for complete processing. This modular approach ensures seamless workflow.

- Seed-Specific Optimizations: While a generic Отгонитель масла черного тмина handles various seeds, optimal performance for unique or challenging oilseeds (e.g., highly fibrous materials or those with delicate compositions) may require custom screw designs, variable speed drives, or specialized pressing cage configurations. This also applies to a dedicated машина для прессования пальмовых ядер.

- Installation and Layout Planning: Vendors provide expert consultation on plant layout and installation to optimize space utilization, ensure operational safety, and streamline material flow, whether for a standalone машина для производства льняного масла or a complex integrated system.

Engaging with a vendor that offers robust customization capabilities ensures that the oil extraction equipment is perfectly aligned with business objectives, operational constraints, and future growth potential.

Application Case Studies: Black Seed Oil Expeller in Action

Real-world application case studies demonstrate the tangible benefits and operational efficiency achieved by businesses utilizing advanced Отгонитель масла черного тмина technology. These examples highlight how the right equipment can lead to increased profitability and superior product quality.

Case Study 1: Organic Nutraceutical Startup

Client: "NutraPure Extracts," a newly established organic health supplement company specializing in cold-pressed oils. Challenge: To produce high-purity black seed oil with maximum nutrient retention for their premium capsule line, starting with limited capital. Solution: Implemented two HP120 Small Capacity Cold Oil Presses. The compact footprint and energy efficiency of the Отгонитель масла черного тмина units were ideal for their initial setup. Results: NutraPure achieved an average black seed oil yield of 48%, significantly higher than their initial projections using alternative methods. The cold pressing process ensured high concentrations of thymoquinone (verified by third-party lab tests), allowing them to market a premium product with strong consumer trust. Their processing costs were reduced by 12% due to minimal residue and lower energy consumption, contributing to a 15% increase in gross profit margins within the first year.

Case Study 2: Regional Specialty Oil Distributor

Client: "Global Harvest Oils," a distributor sourcing and packaging various specialty oils for retail and industrial clients. Challenge: To expand their product portfolio to include fresh, locally pressed flaxseed and linseed oils, requiring a flexible and robust solution that could handle multiple seed types with minimal changeover time. Solution: Installed a medium-capacity машина для производства льняного масла, which also functioned as an efficient средство для вытеснения льняного масла. This unit was integrated with a basic filtration system. Results: Global Harvest Oils successfully launched a new line of regional cold-pressed oils. The machine's adaptability allowed them to switch between flaxseed and linseed processing with only minor adjustments, achieving an average oil yield of 38% for flaxseed and 35% for linseed. This enabled them to capture a new market segment, increasing their overall revenue by 20% in two years, and reducing dependence on external oil suppliers by 30%.

Case Study 3: Cosmetics Ingredient Manufacturer

Client: "Botanical Beauty Solutions," a producer of natural ingredients for the cosmetics industry. Challenge: To ensure consistent high-purity black seed oil suitable for sensitive skincare formulations, meeting strict cosmetic-grade standards and scaling production to meet increasing demand. Solution: Implemented a customized industrial-scale Отгонитель масла черного тмина line with integrated pre-cleaning and a fine filtration module. The system was designed with all food-contact surfaces in SUS316 stainless steel for enhanced corrosion resistance and hygiene. Results: Botanical Beauty Solutions achieved a purity level of 99.8% in their black seed oil, surpassing industry cosmetic standards. The consistent output capacity of 100 kg/hour allowed them to fulfill large-volume orders more efficiently, reducing their lead time by 25%. Customer feedback highlighted the exceptional quality and stability of their oil, leading to several new contracts with major cosmetic brands and solidifying their position as a trusted ingredient supplier.

Frequently Asked Questions (FAQ)

A: The main advantage of cold pressing is the preservation of heat-sensitive nutrients, antioxidants, enzymes, and the natural flavor profile of the oil. Hot pressing involves higher temperatures which can degrade these beneficial compounds and alter the oil's natural characteristics.

A: Most modern oil expellers, including the HP120, are designed to be versatile and can process a variety of oilseeds such as black seed, flaxseed, linseed, sesame, and sunflower. Optimal performance may require minor adjustments to operating parameters (e.g., temperature, pressure) and sometimes different pressing worm configurations, especially for materials like those processed by a машина для прессования пальмовых ядер.

A: With proper operation and routine maintenance, a professionally manufactured Отгонитель масла черного тмина can have a service life of 15-20 years or even longer. Key components like the pressing screw and cage, being subject to wear, might require replacement periodically, but the main frame and motor are built for extreme longevity.

A: A lower residual oil content in the press cake directly translates to higher oil yield and greater economic efficiency. For instance, reducing residual oil from 10% to 5% can significantly increase the total oil recovered, which is particularly impactful for high-value oils like black seed oil.

A: Yes, many vendors offer modular solutions. A Отгонитель масла черного тмина can be integrated with pre-treatment equipment (cleaning, de-hulling), post-extraction filtration, and even full установка по переработке льняного масла or a complete линия по переработке льняного масла for industrial-scale operations to achieve refined, bottled products.

Lead Time, Warranty, and Customer Support

At OilMillChina, we understand that investment in a Отгонитель масла черного тмина is critical to your operations. Our commitment extends beyond providing high-quality machinery to ensuring comprehensive support throughout the lifecycle of your equipment.

Lead Time and Fulfillment:

Standard models like the HP120 Small Capacity Cold Oil Press typically have a lead time of 2-4 weeks from order confirmation to shipment, subject to current inventory and production schedules. For customized solutions or larger industrial lines, lead times may range from 6-12 weeks depending on the complexity and scope of the project. We offer global shipping, working with trusted logistics partners to ensure timely and secure delivery to your facility. Our logistics team handles all necessary documentation for international customs clearance.

Warranty Commitments:

All our Отгонитель масла черного тмина units come with a standard 12-month warranty covering manufacturing defects and component failures under normal operating conditions. Key wear parts such as the pressing screw and cage are guaranteed against premature failure due to material or manufacturing flaws for a specified period. Extended warranty options are available upon request for enhanced peace of mind. Our warranty policies are transparent and designed to protect your investment.

Dedicated Customer Support:

- Technical Assistance: Our team of experienced engineers provides prompt technical support, available via phone, email, and video conferencing to troubleshoot issues and provide operational guidance.

- Spare Parts Availability: We maintain a comprehensive inventory of genuine spare parts to minimize downtime. Parts can be dispatched globally, often within 24-48 hours for critical components.

- Installation and Training: For larger systems or upon client request, we offer on-site installation supervision and comprehensive operational and maintenance training for your personnel, ensuring they are fully proficient in operating your new отгонитель льняного масла or пресс для льняного масла.

- After-Sales Service: Our commitment continues long after the sale with proactive follow-ups, advice on optimizing performance, and assistance with upgrades as your business evolves.

Choosing OilMillChina means partnering with a company dedicated to your success, providing reliable products and unparalleled customer service for your oil extraction needs.

References

- ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

- European Committee for Standardization. EN 60204-1: Safety of machinery – Electrical equipment of machines – Part 1: General requirements.

- American National Standards Institute (ANSI). Various standards related to mechanical engineering and safety.

- "Black Seed (Nigella Sativa) Oil: A Critical Review of Its Chemical Composition and Pharmacological Properties." Journal of Ethnopharmacology.

- "Cold Pressing of Oilseeds: A Review of Parameters and Equipment." Industrial Crops and Products.

- "Impact of Extraction Methods on the Quality of Flaxseed Oil." Food Chemistry.

Это последняя статья

-

Efficient Black Seed Oil Expeller | High Yield Oil Press Machine

НовостиAug.28,2025

-

Energy Efficiency of Multi Seed Oil Press Machines

НовостиAug.23,2025

-

Troubleshooting Common Cottonseed Disc Sheller Issues

НовостиAug.23,2025

-

The Best Oilseed Press Machines for Organic Oil Production

НовостиAug.23,2025

-

Common Maintenance Issues with Press Filter Machines

НовостиAug.23,2025

-

High-temperature Performance of Vertical Oil Filters

НовостиAug.23,2025