ઓગસ્ટ . 23, 2025 00:38 યાદી પર પાછા

Common Maintenance Issues with Press Filter Machines

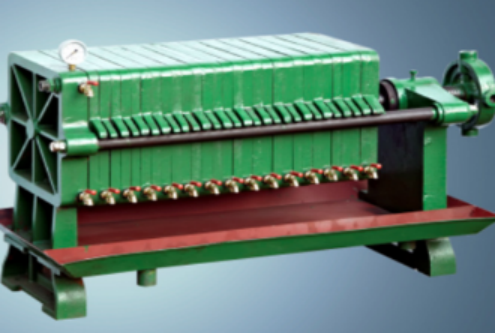

Press filter machines are workhorses in industries like wastewater treatment, mining, and food processing, separating solids from liquids with precision. However, like any industrial equipment, press filter machine, press filter, and plate press filter models face common maintenance issues that can disrupt operations if not addressed promptly. Hebei Huipin Machinery Co., Ltd., a large-scale grain and oil equipment enterprise, understands the importance of reliable filtration systems. Along with its subordinate companies, Dingzhou Yongsheng and Wanli Grain and Oil Machinery, the company collaborates with research institutions to develop durable press filter solutions. Their expertise in complete oil production line equipment extends to designing machines that are easier to maintain, but even the best systems require regular care to avoid downtime. Let’s explore the most frequent maintenance challenges and how to tackle them.

Filter Plate Problems in Plate Press Filter

- Warping and Misalignment: Plate press filter plates are prone to warping from repeated pressure and temperature changes. This misalignment causes uneven sealing, leading to leaks around the edges. To fix this, inspect plates weekly for signs of bending; replace severely warped ones and realign minorly distorted plates using calibration tools.

- Cracked or Damaged Surfaces: The porous surfaces of filter plates can crack due to excessive pressure or rough handling. Cracks allow unfiltered material to bypass the filtration process, reducing efficiency. Regularly check for cracks—small ones can be patched with epoxy, but large cracks require plate replacement. Using high-quality, impact-resistant plates (like those from Hebei Huipin’s designs) minimizes this risk.

- Clogged Drainage Ports: Solid particles can block the drainage ports on plate press filter plates, trapping filtrate and slowing down the process. Clean ports daily with a soft brush or compressed air to prevent buildup, especially when processing high-sediment materials.

Hydraulic System Issues in Press Filter Machine

- Leaking Hoses and Seals: The hydraulic system in a press filter machine uses hoses and seals to maintain pressure. Over time, hoses degrade from oil exposure, and seals harden, causing leaks. Inspect these components monthly—replace cracked hoses and worn seals with compatible, high-pressure-rated alternatives. Using hydraulic fluids recommended by the manufacturer also extends seal life.

- Pressure Fluctuations: Inconsistent pressure in a press filter often stems from air in the hydraulic lines or a failing pump. Bleed air from the system by opening bleed valves during startup; if fluctuations persist, check the pump for worn pistons or clogged filters and repair or replace as needed.

- Slow or Unresponsive Movement: When the hydraulic system struggles to open or close the filter plates, it may be due to a clogged valve or low fluid levels. Clean valves with solvent to remove debris and top up hydraulic fluid to the recommended level, ensuring it’s free of contaminants.

Sealing and Gasket Failures in Press Filter

|

Issue |

Cause |

Solution |

|

Gasket Hardening |

Exposure to high temperatures or chemicals |

Replace with heat- and chemical-resistant gaskets; store spares in cool, dry conditions |

|

Uneven Seal Compression |

Misaligned plates or worn hinges |

Realign plates and lubricate hinges; adjust pressure settings for uniform compression |

|

Leaks Between Plates |

Damaged gaskets or foreign debris |

Clean sealing surfaces thoroughly; replace gaskets with proper fit for the press filter મોડેલ |

|

Reduced Seal Lifespan |

Over-tightening or under-tightening |

Follow manufacturer torque guidelines when securing plates; use torque wrenches for precision |

This table highlights how proactive care can prevent most sealing issues in press filter machine systems.

Clogging and Cake Release Problems in Press Filter

- Filter Media Clogging: The cloth or membrane media in a press filter machine can clog with fine particles, reducing flow rates. To resolve this, backwash media daily with clean water or a mild detergent (avoid harsh chemicals that damage fabric). For persistent clogs, soak media in a specialized cleaning solution weekly.

- Poor Cake Release: When the solid cake (filtered material) sticks to filter plates, it slows down cycle times and requires manual scraping, risking plate damage. This often happens due to insufficient drying time or media incompatibility. Adjust the drying phase to ensure the cake is firm before releasing; use anti-stick media coatings for sticky materials like oils or adhesives.

- Uneven Cake Formation: Inconsistent cake thickness across plates in a plate press filter indicates uneven pressure distribution. Calibrate the hydraulic system to ensure uniform pressure; also, check that all plates are properly aligned to promote even filtration.

Press Filter FAQS

How Often Should a Press Filter Machine Be Inspected?

A press filter machine should undergo daily visual inspections (checking for leaks, clogs) and weekly detailed checks (hydraulics, plates). Major overhauls, including media replacement, are recommended every 6–12 months depending on usage intensity.

What Causes a Plate Press Filter to Take Longer to Cycle?

Slow cycling in a plate press filter is often due to clogged media, hydraulic pressure issues, or drained plates. Clean the media, check hydraulic pressure, and ensure drainage ports are clear to restore normal cycle times.

Can I Use Any Replacement Parts for a Press Filter?

No, using generic parts for a press filter can cause mismatches (e.g., ill-fitting gaskets or weak plates) leading to more issues. Use manufacturer-approved or high-quality compatible parts—Hebei Huipin’s designs often include standardized parts for easier replacement.

How Do I Prevent Corrosion in a Press Filter Machine?

Prevent corrosion in a press filter machine by cleaning it thoroughly after use, especially when processing corrosive materials. Apply anti-corrosion coatings to metal surfaces annually and use corrosion-resistant hydraulic fluids to protect the system.

Where Can I Get Maintenance Support for My Press Filter?

Hebei Huipin Machinery Co., Ltd. offers maintenance guidance for their press filter and plate press filter models, leveraging their expertise in durable equipment design. Their team can advise on parts replacement and troubleshooting. Visit their website to connect with support and explore maintenance resources.

-

Energy Efficiency of Multi Seed Oil Press Machines

સમાચારAug.23,2025

-

Troubleshooting Common Cottonseed Disc Sheller Issues

સમાચારAug.23,2025

-

The Best Oilseed Press Machines for Organic Oil Production

સમાચારAug.23,2025

-

Common Maintenance Issues with Press Filter Machines

સમાચારAug.23,2025

-

High-temperature Performance of Vertical Oil Filters

સમાચારAug.23,2025

-

Key Features of High-performance Horizontal Oil Filters

સમાચારAug.23,2025