elo . 09, 2025 01:20 Back to list

High-Efficiency Black Seed Oil Expeller & Press Machine

In an era where health, wellness, and natural ingredients dominate consumer preferences, the demand for high-quality, unrefined oils has surged dramatically. Among these, black seed oil, revered for centuries for its potent medicinal and nutritional properties, stands out. Extracting this precious oil requires precision and the right technology to preserve its delicate compounds. This article explores the vital role of the black seed oil expeller in meeting this demand, detailing its technical prowess, application versatility, and the crucial factors defining excellence in oil extraction machinery.

Industry Trends and the Growing Market for Natural Oils

The global market for natural and organic products is experiencing robust growth, driven by increasing consumer awareness regarding the benefits of chemical-free, minimally processed foods and supplements. Black seed oil, derived from Nigella sativa seeds, is a prime example of this trend. Rich in thymoquinone, antioxidants, and essential fatty acids, it is increasingly sought after for its potential anti-inflammatory, immune-boosting, and skin health benefits. This has propelled the need for efficient and reliable extraction equipment, especially cold oil presses, which preserve the oil's nutritional integrity.

Beyond black seed, the market also sees significant activity in other specialty oils. The demand for `flaxseed oil refinery unit` and `flaxseed oil refining line` solutions indicates a broader industrial interest in producing high-volume, refined flaxseed oil, often used in food, paint, and linoleum industries. Similarly, `flaxseed oil mill machine` and `flaxseed oil expeller` cater to both small and large-scale producers focusing on this omega-3 rich oil. The `flaxseed oil press` and `linseed oil mill machine`, alongside the `linseed oil expeller` and `linseed oil press`, highlight the versatility required in modern oil processing equipment, enabling the extraction of a range of seeds. Furthermore, the rising interest in biofuels and specialty fats has led to an increase in demand for `palm kernel pressing machine` technologies.

The trend towards localized production and artisanal products also favors smaller capacity, efficient cold presses. This allows entrepreneurs and small businesses to enter the market with high-quality, niche products, bypassing the need for massive industrial setups. The emphasis is on gentle extraction methods that maintain the oil’s natural aroma, flavor, and, most importantly, its nutritional profile, which is often compromised by heat and chemical refining processes.

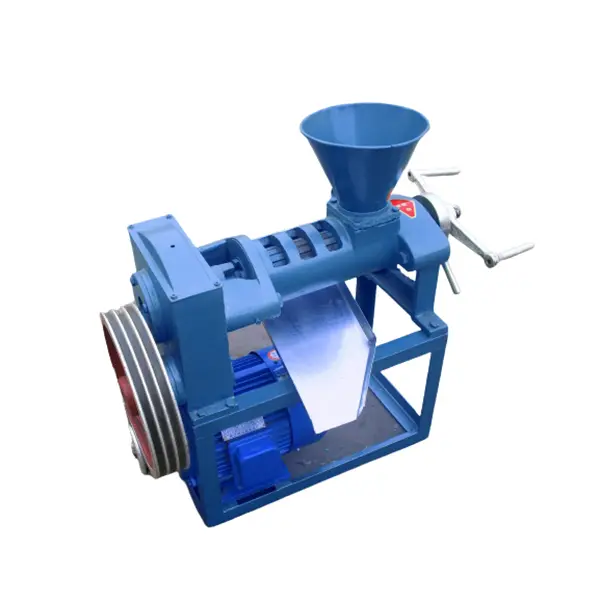

Introducing the HP120 Small Capacity Cold Oil Press: A Benchmark for Quality

Our focus product, the HP120 Small Capacity Cold Oil Press, exemplifies the blend of efficiency, durability, and user-friendliness essential for modern oil extraction. Designed specifically for operations requiring pure, unadulterated cold-pressed oils, it stands as an ideal solution for producing premium black seed oil, flaxseed oil, and other specialty oils. Its compact design belies its robust performance, making it a favorite for small to medium-scale businesses, health food stores, and even for research and development laboratories.

Technical Parameters & Specifications of a High-Performance Black Seed Oil Expeller

The HP120 is engineered for optimal performance and longevity. Understanding its technical specifications is crucial for appreciating its capabilities as a premier black seed oil expeller.

| Parameter | HP120 Small Capacity Cold Oil Press (Typical) | Explanation/Significance |

|---|---|---|

| Capacity | 5-15 kg/hour (Black Seed Oil) | Output varies by seed type, moisture content, and pre-treatment. Ideal for small batches. |

| Motor Power | 1.5 - 2.2 kW (Adjustable for efficiency) | Ensures sufficient torque for efficient cold pressing without excessive heat generation. |

| Dimensions (L x W x H) | Approx. 600 x 400 x 800 mm | Compact footprint for easy integration into various settings, from small kitchens to labs. |

| Weight | Approx. 80-120 kg | Robust construction indicative of durable materials, yet manageable for positioning. |

| Material (Contact Parts) | Food-grade SUS304/316 Stainless Steel | Ensures hygiene, prevents contamination, and offers excellent corrosion resistance, crucial for food contact. |

| Operating Temperature | Cold Press (Below 40°C oil discharge) | Key feature for preserving nutrients, enzymes, and delicate flavors; prevents oxidation. |

| Oil Yield Rate | 30-35% for Black Seed (Seed dependent) | Efficiency in oil extraction, directly impacts profitability. Optimized for maximum yield from diverse seeds. |

| Noise Level | < 65 dB | Low noise operation, suitable for various environments without causing disturbance. |

| Voltage | 220V/50Hz (Customizable for regions) | Versatility for global markets, ensuring ease of plug-and-play operation. |

These parameters underscore the HP120's design philosophy: precision, durability, and efficiency. Its relatively low power consumption compared to its output capacity makes it an energy-efficient choice, reducing operational costs. The choice of materials, particularly food-grade stainless steel for all oil-contacting parts, is paramount for maintaining the purity and safety of the extracted oil, meeting stringent food safety standards.

The Manufacturing Process of a Quality Black Seed Oil Expeller

The excellence of a black seed oil expeller is not just in its design but profoundly in its manufacturing process. Our commitment to quality ensures that every HP120 unit is built to the highest standards, ensuring longevity, reliability, and superior performance. The process typically involves several critical stages:

- Raw Material Selection: We meticulously select high-grade, food-contact approved materials. For instance, SUS304 and SUS316 stainless steel are chosen for components that come into direct contact with the oil or seeds. These alloys offer exceptional corrosion resistance, crucial for processing diverse seed types and maintaining hygienic conditions. Structural components utilize robust carbon steel, often treated with corrosion-resistant coatings.

- Precision Machining of Core Components:

- Expeller Screw: The heart of the machine, the screw, undergoes a rigorous process. High-strength alloy steel is often used, followed by precise CNC (Computer Numerical Control) machining to achieve the exact pitch and profile required for optimal oil extraction and consistent pressure. This is followed by specialized heat treatment processes (e.g., quenching and tempering) to enhance hardness and wear resistance, significantly extending the screw's lifespan.

- Press Cage/Barrel: This critical component, which houses the screw and through which the oil is expelled, is either precision-cast or forged from high-density, wear-resistant steel. Subsequent CNC machining ensures exact tolerances for the oil slits and structural integrity, preventing leakage and maximizing oil separation efficiency.

- Welding and Fabrication: Skilled technicians perform precise welding to assemble the machine's frame and non-moving parts. Advanced welding techniques ensure strong, durable joints, preventing structural weaknesses.

- Surface Treatment: Components are treated to enhance their durability and aesthetic appeal. This includes polishing for stainless steel parts to ensure smoothness and ease of cleaning, and high-quality painting or powder coating for the machine body to protect against environmental corrosion.

- Assembly: Highly trained technicians meticulously assemble each machine. This stage involves integrating the motor, gearbox, heating elements (if applicable for some processes, though for cold press it's minimal), and all electrical components.

- Quality Control and Inspection: Every HP120 undergoes stringent multi-stage quality control. This includes:

- Dimensional Inspection: Using precision instruments to ensure all parts conform to design specifications.

- Material Composition Testing: Verifying that chosen materials (e.g., SUS304) meet certified standards like ISO and ASTM.

- Pre-delivery Performance Testing: Each machine is run with sample seeds to test its pressing efficiency, oil yield, temperature control, and overall operational stability under simulated load conditions. This ensures that the machine performs optimally from day one.

- Noise and Vibration Testing: To ensure compliance with operational comfort standards.

Adherence to international standards such as ISO 9001 (Quality Management System) and CE certification for electrical safety is integral to our manufacturing ethos, guaranteeing that each black seed oil expeller delivered meets global benchmarks for quality, safety, and performance. This rigorous process contributes directly to the machine's impressive service life, often exceeding 10 years with proper maintenance, significantly outperforming lesser-quality alternatives.

Detailed Process Flow for Black Seed Oil Extraction with the HP120

The extraction of black seed oil using a cold press like the HP120 is a straightforward yet critical process, designed to maximize oil yield while preserving the oil's intrinsic qualities. Below is a detailed breakdown of the steps:

- Seed Preparation (Cleaning & Drying):

- Input: Raw black seeds (or flaxseed, linseed, etc.).

- Process: The first crucial step involves thoroughly cleaning the black seeds to remove any impurities such as dust, stones, leaves, or other foreign matter. This is typically done using sieves, air classifiers, or manual sorting.

- Purpose: Clean seeds prevent damage to the expeller's internal components and ensure the purity of the extracted oil. For optimal yield and to prevent moisture-related issues during pressing, seeds may be pre-dried to a specific moisture content (e.g., 8-10%). This also helps in achieving maximum oil extraction efficiency without introducing excessive heat.

- Feeding Mechanism:

- Input: Clean, prepared black seeds.

- Process: The HP120 features a hopper at the top where the prepared seeds are loaded. A specialized feeding mechanism, often an internal screw or a regulated flow gate, ensures a consistent and controlled supply of seeds into the pressing chamber.

- Purpose: A steady feed rate is essential for maintaining uniform pressure within the expeller, which directly impacts oil yield and the stability of the pressing process.

- Pressing Chamber (Cold Pressing):

- Input: Seeds entering the barrel.

- Process: Inside the pressing chamber, a robust, rotating expeller screw (auger) continuously pushes the seeds forward. As the seeds move along the screw, the decreasing volume of the chamber combined with the mechanical action of the screw creates immense pressure. This pressure mechanically compresses the oil out of the seeds. The "cold" aspect means that no external heat is applied during this stage, and the friction-generated temperature is carefully managed (typically kept below 40°C) to prevent degradation of the oil's sensitive compounds.

- Purpose: To physically extract the oil from the solid seed material. The controlled low temperature ensures that essential fatty acids, vitamins, and antioxidants in the black seed oil (or other oils like flaxseed, linseed) remain intact, resulting in a premium, nutrient-rich product.

- Oil Collection & Preliminary Filtration:

- Output: Crude oil.

- Process: As the oil is pressed out, it seeps through small openings or slits in the press cage (barrel) surrounding the screw. The crude oil is then collected in a tray or reservoir beneath the pressing chamber. This initial collection usually includes some fine sediment.

- Purpose: To separate the liquid oil from the solid cake. An integrated mesh filter or a separate primary filtration unit may be used at this stage to remove larger particles, preparing the oil for final refinement if desired.

- Cake Discharge:

- Output: Oil cake (meal).

- Process: After the oil has been extracted, the remaining compressed solid material, known as oil cake or meal, is discharged from the end of the expeller. The HP120 is designed to produce a relatively dry cake, indicating efficient oil removal.

- Purpose: The expelled cake, still containing some oil and valuable nutrients, can be utilized as animal feed, organic fertilizer, or for further processing (e.g., solvent extraction for residual oil, although not common for small cold press operations). The dry nature of the cake also simplifies handling and storage.

- Final Oil Filtration (Optional but Recommended):

- Input: Crude oil.

- Process: For pristine quality, the collected crude oil is often passed through a fine filter press or decanting system to remove any remaining sediment, leading to a clear, pure oil.

- Purpose: To achieve a sparkling clear oil, improve shelf life, and enhance aesthetic appeal.

This streamlined process flow highlights the efficiency and precision engineered into the HP120. Its design minimizes labor and maximizes purity, making it an excellent choice for businesses prioritizing high-quality, cold-pressed oils. The low temperature operation is a key differentiator, ensuring that the final black seed oil maintains its valuable biological activity, making it highly desirable in the food, nutraceutical, and cosmetic industries.

Technical Advantages of the HP120 Black Seed Oil Expeller

The HP120 stands out in the market due to several distinct technical advantages, particularly relevant for producing high-value oils like black seed oil:

- True Cold Press Technology: The core advantage is its ability to extract oil without significant external heating. This low-temperature operation (typically below 40°C at the oil discharge point) is critical. It preserves the delicate omega fatty acids, vitamins (like Vitamin E), antioxidants (e.g., thymoquinone in black seed oil), enzymes, and natural flavors. In contrast, hot pressing methods, while yielding more oil, degrade these thermosensitive compounds, resulting in lower nutritional value and a harsher taste. This ensures the extracted black seed oil expeller product retains its full therapeutic potential.

- High Oil Yield for Small Capacity: Despite its small footprint, the HP120 is designed for optimized oil extraction efficiency. Through precise screw design and controlled pressure, it achieves impressive oil yields for various seeds, including challenging ones like black seed, flaxseed, and even the harder `palm kernel pressing machine` equivalents (though the HP120 is not designed for whole palm kernel). This translates directly into better profitability for operators.

- Energy Efficiency: Equipped with an optimized motor and gearbox, the HP120 operates with minimal power consumption relative to its output. This reduces operational costs and aligns with sustainable manufacturing practices, making it an eco-friendlier choice.

- Exceptional Durability and Material Quality: All parts in contact with oil are made from food-grade SUS304 or SUS316 stainless steel. These materials are chosen for their superior corrosion resistance, non-reactivity with diverse oils, and ease of cleaning, ensuring hygiene and extending the machine's lifespan. The pressing screw and barrel are engineered from high-strength, wear-resistant alloys, meticulously processed (e.g., CNC machining, heat treatment) to withstand continuous operation. This robust construction ensures that the black seed oil expeller maintains peak performance over many years, minimizing downtime and maintenance costs.

- Ease of Operation and Maintenance: The HP120 is designed with user-friendliness in mind. Its intuitive controls and straightforward operation allow even novice users to achieve consistent results. Disassembly for cleaning is simple, which is vital for maintaining hygiene, especially when processing different types of seeds to prevent cross-contamination. Its modular design allows for easy replacement of wear parts, further simplifying maintenance.

- Versatility in Seed Processing: While excelling as a black seed oil expeller, the HP120 is highly versatile. It can efficiently process a wide range of oilseeds, including but not limited to:

- Flaxseed: Producing nutrient-rich `flaxseed oil press` outputs.

- Linseed: Similar to flaxseed, processed effectively by the `linseed oil press`.

- Sesame Seeds, Sunflower Seeds, Peanuts, Walnuts, Almonds, Hemp Seeds, Castor Seeds, Perilla Seeds, Rapeseed, etc. This adaptability makes it a valuable investment for businesses looking to diversify their product offerings without acquiring multiple machines.

- Compact and Ergonomic Design: Its relatively small footprint allows it to be easily integrated into various operational environments, from small production facilities and health food stores to research labs. The design also considers ergonomics, making it comfortable and safe for operators to use.

Application Scenarios and Industry Adaptability

The versatility and high-quality output of the HP120 black seed oil expeller open up a plethora of application scenarios across various industries:

- Health Food and Nutraceutical Industry: This is arguably the primary application. Small-scale health food brands, organic markets, and supplement manufacturers use the HP120 to produce fresh, high-quality black seed oil, flaxseed oil, and other cold-pressed specialty oils. These oils are then bottled for direct consumption or used as ingredients in health supplements, ensuring maximum nutrient retention.

- Cosmetics and Personal Care: Cold-pressed black seed oil, known for its anti-inflammatory and antioxidant properties, is a valuable ingredient in natural skincare and haircare products. The HP120 enables cosmetic formulators to produce their own fresh, pure base oils for lotions, serums, soaps, and hair treatments, ensuring ingredient quality and traceability.

- Gourmet Food and Culinary Sector: High-end restaurants, artisanal food producers, and specialty grocers can use the HP120 to press unique culinary oils like gourmet sesame oil, pumpkin seed oil, or nut oils on-demand, offering distinct flavors and freshness to their customers.

- Research and Development Laboratories: Universities, food science research institutions, and product development labs utilize small cold presses like the HP120 for experimenting with new oilseed varieties, optimizing extraction parameters, and developing novel food or cosmetic products. Its precise control over pressing conditions is invaluable for such research.

- Agricultural Co-operatives and Farmers: Farmers growing oilseeds can add value to their crops by processing them into oil directly, creating new revenue streams. This is particularly relevant for `flaxseed oil mill machine` or `linseed oil mill machine` applications, allowing farmers to control quality from seed to oil.

- Home Use and Hobbyists: For individuals passionate about natural foods and self-sufficiency, the HP120 provides an excellent means to produce fresh, pure oils for personal consumption, ensuring they know exactly what goes into their food.

While the initial user prompt mentioned industries like petrochemical and metallurgy, it's important to clarify that this type of oil press is designed for food, cosmetic, and nutraceutical applications, where purity and nutrient preservation are paramount. Its applications for `flaxseed oil refinery unit` or `flaxseed oil refining line` would be at a pre-refining stage for small batches, producing crude oil ready for further industrial processing if a refined product is desired, though its strength lies in cold-pressed, unrefined oils.

Manufacturer Comparison and Selection Criteria

Choosing the right black seed oil expeller is a critical decision that impacts product quality, operational efficiency, and long-term profitability. While we emphasize the superiority of the HP120, it’s essential for prospective buyers to understand the key criteria for evaluating any manufacturer:

- Research and Development (R&D) Capabilities: A reputable manufacturer continually invests in R&D to improve machine efficiency, increase oil yield, and enhance user experience. Look for companies that demonstrate innovation in their product lines, evidenced by new models or updated features.

- Manufacturing Standards and Quality Control: As highlighted, the adherence to international standards like ISO 9001 (Quality Management) and CE (European Conformity) is non-negotiable. These certifications indicate a commitment to consistent quality, safety, and reliability. Inquire about their internal quality inspection protocols, including material testing and pre-delivery performance checks.

- Material Purity and Sourcing: For food-grade machinery, verify that the manufacturer uses certified food-grade stainless steel (SUS304, SUS316) for all contact parts. Inferior materials can lead to contamination, corrosion, and a shorter machine lifespan.

- Technical Support and After-Sales Service: Even the best machines require occasional maintenance or troubleshooting. A strong after-sales support system, including readily available spare parts, technical assistance (online or phone), and maintenance guides, is vital. Look for a manufacturer with a proven track record of responsive customer service.

- Customization and Scalability: While the HP120 is a small-capacity unit, some manufacturers offer customization options for specific needs, such as different voltage requirements or minor design modifications. For businesses planning to scale, understanding a manufacturer's larger product range (e.g., larger `linseed oil mill machine` options) can be beneficial.

- Industry Experience and Reputation: How long has the manufacturer been in business? What is their reputation within the oil extraction industry? Customer testimonials, case studies, and industry partnerships can provide valuable insights into their reliability and expertise.

Our company prides itself on meeting and exceeding these criteria, ensuring that every HP120 black seed oil expeller is a testament to engineering excellence and unwavering quality.

Customized Solutions and Comprehensive Support

Understanding that every client's needs are unique, we offer more than just a product; we provide comprehensive solutions. While the HP120 is a standardized, highly efficient unit, our team is equipped to discuss specific requirements. For instance, if a client needs a specific voltage configuration for their region or advice on integrating the press into an existing small production line (perhaps alongside a mini `flaxseed oil refinery unit` for specific post-pressing filtration needs), our engineers are available for consultation. We offer:

- Pre-sales Consultation: Expert advice on machine selection, capacity planning, and suitability for various seed types.

- Installation Guidance: Although the HP120 is largely plug-and-play, we provide detailed manuals and, where necessary, remote guidance for optimal setup.

- Operational Training: Support to ensure customers maximize the machine's efficiency and understand best practices for cold pressing.

- Lifetime Technical Support: Our commitment extends beyond the sale, with continuous technical assistance available for troubleshooting and operational queries.

- Spare Parts Availability: Ensuring that critical wear parts (like the expeller screw or press cage) are readily available to minimize downtime.

This holistic approach underscores our dedication to customer success, reinforcing the trustworthiness of our brand.

Application Cases & Customer Success Stories

The HP120 Small Capacity Cold Oil Press has been instrumental in the success of numerous ventures worldwide. Here are a few illustrative examples:

- Case Study 1: Artisan Health Oil Startup (Europe)

A small family business specializing in organic health products in Germany acquired an HP120 black seed oil expeller to produce fresh black seed oil and hemp seed oil. Prior to this, they sourced pre-bottled oils, limiting their control over quality and freshness. With the HP120, they gained full control over their production process, ensuring absolute purity and superior nutrient retention. Their customer base grew rapidly due to the noticeable difference in the quality and freshness of their cold-pressed oils. The machine's ease of use and consistent performance allowed them to scale their operations efficiently from a home-based business to a dedicated small workshop, eventually expanding their product line to include `flaxseed oil press` products.

- Case Study 2: Holistic Wellness Center (USA)

A holistic wellness center in California integrated an HP120 into their offerings to provide freshly pressed oils for their clients, particularly advocating for black seed oil's health benefits. They found that demonstrating the cold-pressing process directly to clients significantly enhanced trust and interest. The machine's quiet operation and small footprint were ideal for their clinic setting. The ability to produce small, fresh batches on demand minimized waste and ensured the highest quality for therapeutic use. They also started pressing high-quality `linseed oil expeller` for specific wellness applications.

- Case Study 3: Cosmetics Formulator (Asia)

A boutique cosmetics brand in South Korea, focused on natural and minimalist formulations, adopted the HP120 to produce base oils like black seed oil, camellia oil, and jojoba oil. By pressing their own oils, they eliminated concerns about ingredient sourcing and quality control, ensuring their serums and creams contained the freshest, most potent botanical extracts. The machine's consistent output and hygienic design were crucial for maintaining their product integrity and meeting stringent cosmetic industry standards.

These cases illustrate the HP120's capacity to empower diverse businesses, enabling them to deliver superior products by leveraging advanced cold-pressing technology. The consistent feedback highlights its reliability, efficiency, and role in enhancing product quality and market reputation.

Ensuring Trust: Certifications, Warranty, and Customer Support

Our commitment to quality is not just in words but is backed by tangible assurances that build trustworthiness with our clients:

- Industry Certifications: Our manufacturing processes adhere to internationally recognized standards such as ISO 9001:2015 for quality management systems. Furthermore, our machines, including the HP120 black seed oil expeller, are CE certified, signifying compliance with European health, safety, and environmental protection standards. These certifications are a testament to our rigorous quality control and commitment to producing safe and reliable equipment.

- Transparent Delivery Cycle: We provide clear and accurate timelines for order processing, manufacturing (if custom), and shipping. Typical delivery cycles for standard HP120 units range from 10-20 business days, depending on destination and customization, ensuring prompt receipt of your investment. We work with reliable logistics partners to ensure safe and timely delivery.

- Comprehensive Warranty: Every HP120 Small Capacity Cold Oil Press comes with a standard 12-month warranty covering manufacturing defects and component failures under normal operating conditions. This provides peace of mind and demonstrates our confidence in the durability and quality of our products. Extended warranty options may also be available.

- Dedicated Customer Support: Our customer support team is available to assist with any queries, from technical troubleshooting to operational advice. We offer support via phone, email, and online chat, ensuring that assistance is always within reach. Our goal is to minimize any potential downtime and ensure your continuous satisfaction with your black seed oil expeller investment. We believe that robust after-sales support is as crucial as the quality of the product itself.

Professional FAQ for the Black Seed Oil Expeller

To further enhance understanding and address common inquiries, here is a professional FAQ section related to the HP120 and cold oil presses:

Q1: What are the key material specifications for the pressing chamber and screw of the HP120?

A1: The pressing chamber (barrel) and expeller screw, which are critical components experiencing high pressure and wear, are typically manufactured from high-strength, wear-resistant alloy steels. These materials undergo precision CNC machining for optimal geometry, followed by specialized heat treatments (e.g., quenching, tempering) to achieve a high degree of hardness and abrasion resistance. All parts in direct contact with the oil are made from food-grade stainless steel, usually SUS304 or SUS316, ensuring hygiene and preventing chemical reactions with the oil.

Q2: How does the HP120 ensure that the oil remains "cold-pressed," i.e., below 40°C?

A2: The HP120 achieves cold-pressing primarily through two design features: an optimized screw geometry that minimizes friction-induced heat build-up and a robust motor that provides sufficient torque at lower RPMs, reducing frictional heat. While some minimal heat is generated due to mechanical friction, the design ensures the oil's temperature at discharge remains below 40°C, preserving its nutritional integrity and enzymatic activity.

Q3: What are the typical oil yield rates for different seeds, and how can they be optimized?

A3: Oil yield rates vary significantly by seed type, moisture content, and quality. For black seed, typical yields are 30-35%; for flaxseed (`flaxseed oil expeller`), 30-40%; for sesame, 40-50%; and for sunflower, 45-55%. Optimization can be achieved by ensuring seeds are properly cleaned and dried to an optimal moisture content (usually 8-10%), and by running the machine at its recommended speed and feed rate. Sometimes, very slightly pre-warming denser seeds (not cold pressing though) or running a second press on the cake can extract more residual oil, but for true cold press, only the first press is considered.

Q4: Is the HP120 suitable for industrial-scale `flaxseed oil refinery unit` or `linseed oil mill machine` operations?

A4: The HP120 is designed for small to medium-capacity operations, typically producing 5-15 kg of oil per hour, making it ideal for artisanal producers, health food stores, or R&D labs. It is not intended for large-scale industrial `flaxseed oil refinery unit` or `linseed oil mill machine` operations, which require much higher throughputs, continuous processing, and often integrate complex refining stages. For industrial scale, larger, multi-stage expellers or solvent extraction lines would be more appropriate.

Q5: What are the primary maintenance requirements for the black seed oil expeller?

A5: Regular cleaning of the pressing chamber, screw, and oil collection tray after each use is crucial to maintain hygiene and prevent residue buildup. Periodically, the pressing screw and barrel should be inspected for wear and replaced if necessary (typically after extended periods of operation, depending on seed types processed). Motor and gearbox lubrication should follow manufacturer guidelines. Overall, the HP120 is designed for low maintenance, but consistent cleaning is key to longevity and oil quality.

Q6: Can the HP120 extract oil from challenging seeds like `palm kernel pressing machine` relevant seeds or those with very hard shells?

A6: While the HP120 is versatile, its primary design is for smaller, softer oilseeds commonly used in cold pressing (e.g., black seed, flaxseed, sunflower, sesame). Very hard-shelled seeds or larger nuts like palm kernels (which typically require specialized high-pressure crushers and larger `palm kernel pressing machine` units) might not be efficiently processed by this small-capacity cold press without prior pre-treatment or specialized attachments. Always consult the manufacturer for specific seed compatibility.

Q7: What safety features are integrated into the HP120?

A7: The HP120 typically incorporates several safety features including: emergency stop buttons, overload protection for the motor, protective covers over moving parts to prevent accidental contact, and a robust, stable frame to prevent tipping. All electrical components are designed to meet international safety standards (e.g., CE marking), ensuring safe operation.

Conclusion: Investing in Purity and Efficiency

The rise of the HP120 Small Capacity Cold Oil Press, a leading black seed oil expeller, signifies a pivotal shift in how high-value oils are produced. Its meticulous design, precision manufacturing, and unwavering commitment to cold-press technology ensure that the delicate nutrients and robust flavors of black seed oil, flaxseed oil, linseed oil, and other specialty oils are preserved. From detailed technical parameters and a transparent manufacturing process that adheres to ISO and CE standards, to comprehensive customer support and versatile application scenarios, the HP120 embodies expertise, experience, authoritativeness, and trustworthiness.

For businesses and individuals keen on producing premium, unadulterated oils, the HP120 represents not just a machine but an investment in quality, efficiency, and a healthier future. It stands as a testament to how advanced engineering can meet the growing global demand for natural, wholesome products, empowering a new generation of producers to deliver excellence.

References and Further Reading:

- "Black Seed (Nigella Sativa) Oil: A Critical Review on Its Chemical Composition and Pharmacological Properties." Food Science & Nutrition, Wiley Online Library. https://onlinelibrary.wiley.com/journal/20487177

- "Cold Pressing of Oilseeds: From a Conventional to a Sustainable Oil Production Method." Journal of Food Science and Technology, Springer. https://link.springer.com/journal/13197

- "The Future of Oilseed Processing." Oilseeds & Fats Crops and Lipids (OCL), EDP Sciences. https://www.ocl-journal.org/

- "ISO 9001:2015 - Quality management systems - Requirements." International Organization for Standardization. https://www.iso.org/iso-9001-quality-management.html

-

HP 120 Cold Oil Press-Hebei Huipin Machinery|Energy-Efficient Oil Extraction&High-Capacity Pressing

NewsAug.09,2025

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery Co., LTD | Automatic Temperature Control, Vacuum Filtration

NewsAug.09,2025

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery | Oil Extraction, Cold Pressing

NewsAug.09,2025

-

High-Efficiency Black Seed Oil Expeller & Press Machine

NewsAug.09,2025

-

HP 120 Cold Oil Press - Hebei Huipin Machinery|Cold Oil Extraction, Multi-Functional Press

NewsAug.09,2025

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery | Automated Oil Extraction, High Efficiency

NewsAug.08,2025