Nov . 07, 2024 18:15 Back to list

Manufacturer of Seed Oil Refining Equipment for Optimal Processing Solutions

The Evolution of Seed Oil Refining Machine Manufacturers

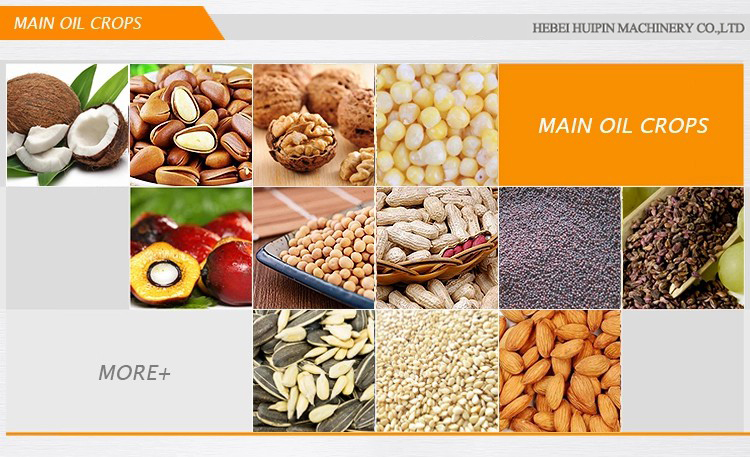

Seed oil refining is a crucial process in the production of edible oils, enabling the extraction of high-quality oil from various seeds like sunflower, canola, and soybean. This process not only enhances the purity and taste of the oil but also extends its shelf life, making it safe for consumption. The evolution of seed oil refining machine manufacturers plays a significant role in meeting the global demand for edible oils, and understanding this evolution is essential for grasping the industry’s current landscape.

Historically, the extraction of oil from seeds was done manually, using basic tools and methods that were labor-intensive and time-consuming. However, with the advent of the industrial revolution in the 18th century, the need for more efficient production methods emerged. This led to the development of mechanical pressing methods, which significantly increased the yield of oil extraction and reduced the time required for processing.

As consumer preferences evolved and the demand for high-quality edible oils increased, manufacturers began to innovate more advanced refining techniques. The emergence of seed oil refining machines revolutionized the industry. These machines automate various stages of the oil refining process, including degumming, neutralization, bleaching, and deodorization. They are designed to ensure that the oil produced meets stringent health and safety standards while retaining its nutritional quality.

Modern seed oil refining machine manufacturers have adopted cutting-edge technologies to enhance the efficiency and effectiveness of their machines. For example, the introduction of solvent extraction methods has allowed for higher oil yields from the same amount of seeds. This technique uses a solvent to dissolve the oil, which is then separated from the seed material. As a result, manufacturers can produce more oil with less raw material, making the process environmentally sustainable and economically viable.

seed oil refining machine manufacturer

Additionally, many manufacturers have focused on creating energy-efficient machines that reduce operational costs for oil processors. These machines often incorporate advanced control systems that optimize energy use and monitor the quality of the oil in real-time. Such innovations not only improve production efficiency but also contribute to sustainability initiatives within the industry.

Another significant trend is the emphasis on automation and smart technology. With the rise of Industry 4.0, many seed oil refining machine manufacturers are integrating IoT (Internet of Things) technologies into their machines. This enables remote monitoring and management of the production process, allowing operators to make timely and informed decisions. The benefits of this smart technology extend to quality control, ensuring that the final product meets market specifications.

Furthermore, as global regulations surrounding food safety continue to tighten, seed oil refining machine manufacturers are required to comply with stringent certifications. This has led to increased investments in research and development to create machines that not only meet safety standards but also improve overall oil quality. Manufacturers are now focusing on designing machines that can handle a wider variety of seeds and oils, catering to diverse consumer demands globally.

In conclusion, the landscape of seed oil refining machine manufacturers has undergone significant transformation over the years. From manual extraction techniques to automation and smart technology, the journey reflects a continuous pursuit of efficiency, quality, and sustainability. As the global demand for high-quality edible oils continues to rise, seed oil refining machine manufacturers will need to remain at the forefront of innovation, ensuring they can meet both consumer expectations and regulatory requirements. Through ongoing advancements, the industry is poised for a future that embraces not only traditional practices but also modern technological solutions, fostering a more efficient and sustainable oil production process.

-

Top Food Oil Refined Unit Companies w/ GPT-4 Turbo Tech

NewsAug.01,2025

-

Premium Black Seed Oil Expeller - High Efficiency Cold Press Oil Machine

NewsJul.31,2025

-

Oil Processing Equipment - High-Efficiency Flaking Machine

NewsJul.25,2025

-

High-Efficiency Peanut Oil Refined Machine for Quality Oil Production Leading Exporters & Companies

NewsJul.08,2025

-

High Efficiency Sunflower Seed Oil Press – Leading Cooking Oil Press Machine Factories & Suppliers

NewsJul.08,2025

-

High-Efficiency Soybean Oil Press Machine – Leading Exporters & Reliable Companies

NewsJul.07,2025