Jan . 14, 2025 10:00 Back to list

cottonseed oil refining unit

Cottonseed oil, a byproduct of cotton production, has gained significant traction in the cooking oil market due to its light texture and mild flavor. Its refining process plays a crucial role in ensuring that the oil is pure, safe, and healthy for consumption. Establishing a cottonseed oil refining unit requires a precise understanding of both the technical processes and the market needs. The following explores the intricacies involved in setting up a cottonseed oil refining unit, ensuring maximum effectiveness and efficiency.

The sustainability of the refining process is another critical component that impacts consumer trust and environmental responsibility. Cottonseed oil refining units that adopt sustainable practices, such as energy-efficient machinery and waste reduction techniques, can gain significant market advantages. Waste management, particularly in dealing with byproducts like soap stock and spent earth, should be designed to minimize environmental impact, possibly even converting waste into valuable side products. Marketing and distribution strategies are equally vital in establishing a cottonseed oil refining unit's success. Understanding market demands, including regional preferences and health trends, allows for more targeted marketing campaigns. Positioning cottonseed oil as a healthier alternative, rich in polyunsaturated fats and vitamin E, aligns well with current health trends. Distribution partnerships should be forged with both local and international vendors to maximize market reach. Digital platforms offer an opportunity to engage directly with end consumers, building brand loyalty through responsive customer service and engaging content about the benefits and uses of cottonseed oil. In conclusion, launching a cottonseed oil refining unit involves a comprehensive approach that blends technical precision, expert knowledge, trust-building measures, and strategic marketing. By focusing on these aspects, a new business can not only meet but exceed market expectations. The journey from raw cottonseed to refined oil is complex yet rewarding, offering both a challenge and an opportunity to contribute positively to the food and health sectors. Through meticulous planning and execution, a refining unit can rise as a leader in a competitive field, providing consumers with a product that is both healthy and ethically produced.

The sustainability of the refining process is another critical component that impacts consumer trust and environmental responsibility. Cottonseed oil refining units that adopt sustainable practices, such as energy-efficient machinery and waste reduction techniques, can gain significant market advantages. Waste management, particularly in dealing with byproducts like soap stock and spent earth, should be designed to minimize environmental impact, possibly even converting waste into valuable side products. Marketing and distribution strategies are equally vital in establishing a cottonseed oil refining unit's success. Understanding market demands, including regional preferences and health trends, allows for more targeted marketing campaigns. Positioning cottonseed oil as a healthier alternative, rich in polyunsaturated fats and vitamin E, aligns well with current health trends. Distribution partnerships should be forged with both local and international vendors to maximize market reach. Digital platforms offer an opportunity to engage directly with end consumers, building brand loyalty through responsive customer service and engaging content about the benefits and uses of cottonseed oil. In conclusion, launching a cottonseed oil refining unit involves a comprehensive approach that blends technical precision, expert knowledge, trust-building measures, and strategic marketing. By focusing on these aspects, a new business can not only meet but exceed market expectations. The journey from raw cottonseed to refined oil is complex yet rewarding, offering both a challenge and an opportunity to contribute positively to the food and health sectors. Through meticulous planning and execution, a refining unit can rise as a leader in a competitive field, providing consumers with a product that is both healthy and ethically produced.

Latest news

-

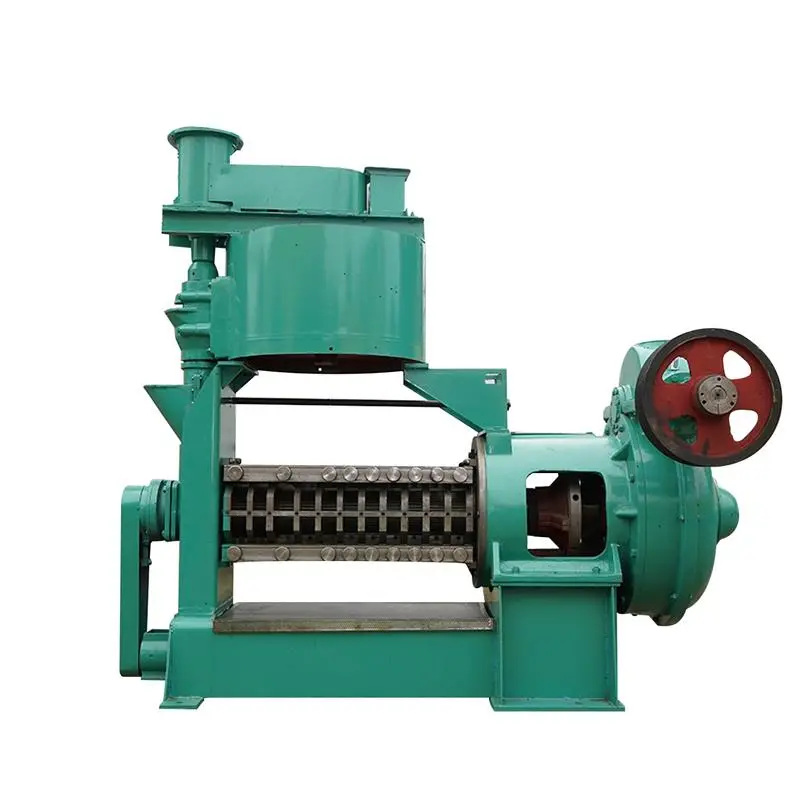

HP290 First Press Oil Expeller Machinery: Efficient Oil Extraction

NewsAug.02,2025

-

Top Food Oil Refined Unit Companies w/ GPT-4 Turbo Tech

NewsAug.01,2025

-

Premium Black Seed Oil Expeller - High Efficiency Cold Press Oil Machine

NewsJul.31,2025

-

Oil Processing Equipment - High-Efficiency Flaking Machine

NewsJul.25,2025

-

High-Efficiency Peanut Oil Refined Machine for Quality Oil Production Leading Exporters & Companies

NewsJul.08,2025

-

High Efficiency Sunflower Seed Oil Press – Leading Cooking Oil Press Machine Factories & Suppliers

NewsJul.08,2025