Oct . 27, 2025 11:15 Back to list

Black Seed Oil Expeller - High Yield, Durable, Energy-Saving

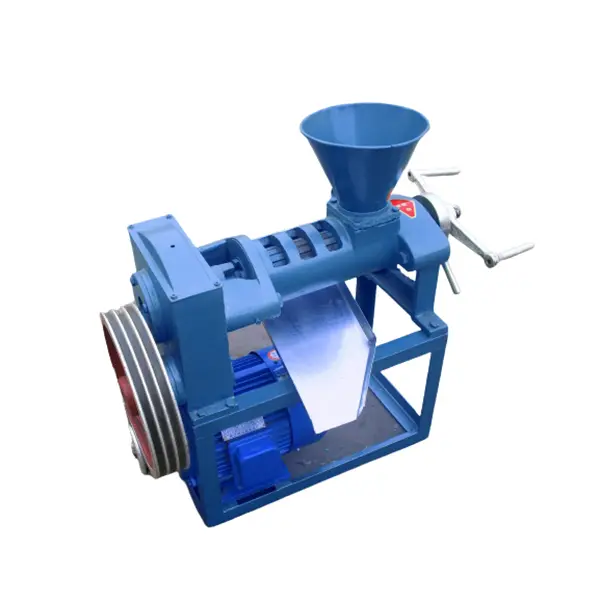

Field Notes on a Workhorse: The HP120 Small Capacity Cold Oil Press

If you’ve been hunting for a dependable Black Seed Oil Expeller, the HP120 from Dingzhou City, Hebei Province, China keeps popping up in conversations—factory floors, trade shows, even WhatsApp groups. I’ve seen it run in small nutraceutical plants and family-owned oil rooms; to be honest, it’s a no-drama machine when dialed in.

Why black seed, and why now?

Black seed (Nigella sativa) oil demand is rising on the back of wellness, clean-label skincare, and functional foods. Cold pressing stays below oxidation thresholds, preserves thymoquinone, and, frankly, tastes better. The Black Seed Oil Expeller HP120 aims to keep outlet oil temps ≤ 60°C, which is where most quality managers want it.

Process flow, real-world

Materials: cleaned black seed (≤ 8–10% moisture) from a screened lot. Methods: light warm-up (not cooking), continuous screw pressing, then gravity settling and 5–10 μm polishing filtration. Testing standards: ISO 659 for oil content, ISO 661 for test prep; routine POV/FFA checks each batch. Service life: nitrided screw flights often run ≈ 6,000–8,000 hours before refurbishment; bearings last longer with cleanrooms and daily wipe-downs. Industries: nutraceutical bottlers, artisanal food brands, cosmetic fillers, and some R&D labs.

HP120 quick specs (as deployed)

| Model | HP120 Small Capacity Cold Oil Press |

| Throughput (Nigella sativa) | ≈ 40–80 kg/h (real-world use may vary by seed grade and moisture) |

| Motor power | 7.5 kW, 380 V / 50 Hz (other voltages optional) |

| Screw speed | ≈ 36–60 rpm adjustable |

| Cold-press temp | ≤ 60°C at outlet, with thermal guard |

| Residual oil in cake | ≈ 8–12% depending on feed |

| Materials | Contact parts SUS304; screw 20CrMnTi, nitrided HRC 58–62 |

| Dimensions / Weight | ≈ 1600 × 700 × 1350 mm / ≈ 650 kg |

| Certifications | CE; ISO 9001; HACCP/ISO 22000-ready environments |

Applications and what users say

- Nutraceutical bottlers targeting thymoquinone retention.

- Clean-label culinary oils for farm shops.

- Cosmetics: serums and balms prefer cold-pressed aroma.

Feedback? “Start-up was boring—in a good way,” one Hebei customer told me. Another said yield went up ≈ 2–3% after tweaking moisture to 7.5%.

Vendor snapshot (apples-to-apples-ish)

| Vendor/Model | Tech | Rated throughput (black seed) | Outlet oil temp | Power | Best use case |

|---|---|---|---|---|---|

| HP120 (this unit) | Cold screw press | ≈ 40–80 kg/h | ≤ 60°C | 7.5 kW | SMEs, premium oil lines |

| Generic open-frame press | Hot/cold screw press | ≈ 30–70 kg/h | 60–85°C (less control) | 5.5–7.5 kW | Budget setups |

| Bench/lab mini press | Single-screw benchtop | ≈ 5–15 kg/h | ≤ 65°C | 1–2 kW | R&D, trials |

Customization and QA

Options include hopper extensions, variable-frequency drive, 304/316L contact upgrades, and dual-stage filtration skid. Factory QA typically follows ISO 9001, with CE conformity files and—where the plant requires—HACCP/ISO 22000 procedures. Acceptance tests often include a 2–4 hour FAT with ISO 659 yield checks and outlet-temp logging.

Field results and maintenance

Typical oil yield from good black seed lots: 30–35% w/w; with careful moisture tuning, I’ve seen 36% once—surprisingly high. Daily SOP: purge, wipe, and check the barrel temperature probe; weekly: inspect cake thickness and motor amps. Spare kits (screw + cage) are worth keeping on-site; service intervals are around 1,000 hours for general inspection.

Bottom line: if you want a steady Black Seed Oil Expeller that respects cold-press quality while staying SME-friendly, the HP120 earns its keep.

Authoritative citations

-

Spiral Oil Press: Efficient Oil Extraction Technology for Sustainable Production

NewsNov.24,2025

-

Efficient Spiral Oil Expellers for Sustainable Oil Extraction | OilMill China

NewsNov.24,2025

-

Comprehensive Guide to Screw Physical Oil Expeller Technology & Benefits

NewsNov.23,2025

-

Durable and Efficient Screw Physical Oil Presses for Sustainable Oil Extraction

NewsNov.23,2025

-

Screw Oil Expeller – Efficient, Sustainable Mechanical Oil Extraction Solutions

NewsNov.22,2025

-

Comprehensive Guide to Cold Oil Expeller: Benefits, Uses & Future Trends

NewsNov.22,2025