Oct . 28, 2025 11:55 Back to list

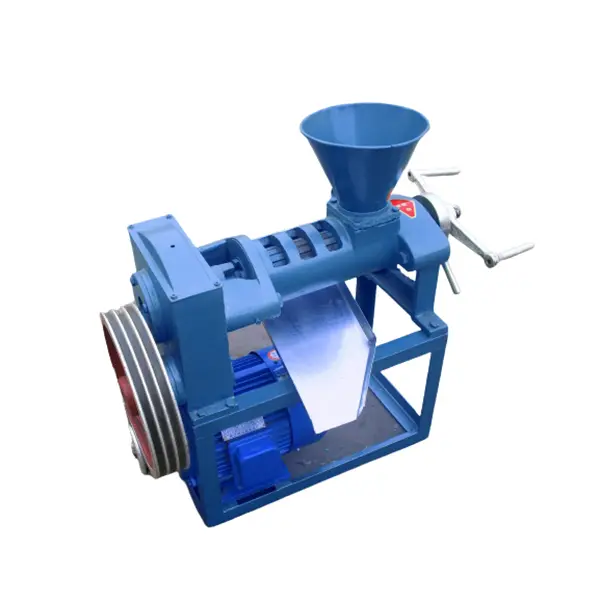

Black Seed Oil Expeller – High Yield, Cold Press, Durable

Field Notes on a Cold-Press Workhorse for Nigella Sativa

I spent a few days last season in Dingzhou City, Hebei Province—factory floors humming, sesame aroma in the air, and yes, black seed (Nigella sativa) ready for trial runs. That’s where I first saw the Black Seed Oil Expeller—the HP120 Small Capacity Cold Oil Press—punch well above its weight. To be honest, the setup looked deceptively simple; the consistency of the output surprised me.

Why cold-press for black seed right now?

The nutraceutical oil market—black seed in particular—is leaning hard into traceability, solvent-free extraction, and gentler thermal profiles. Brands want stable peroxide values, authentic flavor notes, and cleaner labels. In fact, many customers say they’re choosing small-batch expellers not just for yield, but for story and control. That’s where the Black Seed Oil Expeller slot-in really makes sense: boutique runs, quick changeovers, and temperature discipline.

HP120 Snapshot (real-world figures)

| Model | HP120 Small Capacity Cold Oil Press |

| Origin | Dingzhou City, Hebei Province, China |

| Throughput (black seed) | ≈ 25–60 kg/h (depends on seed moisture, conditioning, operator) |

| Motor Power | ≈ 11–15 kW, VFD optional |

| Temp control | Cold-press regime; typical 35–55°C at cake exit (aiming to protect volatiles) |

| Build materials | Food-contact 304 SS (316 optional at wear points) |

| Certifications (typical) | ISO 9001 QA, CE machinery compliance (documentation on request) |

Process flow and QA (how teams really run it)

- Materials: cleaned Nigella sativa seeds (≤ 8% moisture recommended).

- Method: light warm-up of the press, constant feed, gentle back-pressure adjustment; no solvents.

- Filtration: inline mesh + settling tank; optional plate filter for premium clarity.

- Testing: - Moisture & volatiles (ISO 662), - Acid value/FFA (ISO 660), - Peroxide value (AOCS Cd 8b-90/Cd 8-53 family). Real-world target PV: ≤ 5 meq O2/kg for fresh lots.

- Service life: screw/pressing cage ≈ 1,000–3,000 h (seed hardness matters); bearings ≈ 8,000–20,000 h with proper lubrication.

- Industries: nutraceutical and wellness, specialty culinary oils, cosmetics (soaps, serums), R&D labs.

Advantages I’ve noticed with the Black Seed Oil Expeller: quick setup, forgiving learning curve, and cake that’s easy to mill into feed or bakery adjuncts. Yield obviously varies—seed quality is king—but temperature stability helps preserve thymoquinone aroma notes.

Vendor comparison (condensed)

| Option | Capacity (black seed) | Temp Control | After-sales | Notes |

|---|---|---|---|---|

| HP120 Black Seed Oil Expeller | ≈ 25–60 kg/h | Good, stable low-temp pressing | Factory-supported; spares available | Balanced price/performance |

| Bench-top hydraulic press | ≈ 5–15 kg/h | Excellent but slower | Varies by maker | Great for micro-batches, higher labor |

| Budget no-name screw press | ≈ 20–40 kg/h (claimed) | Inconsistent | Limited | Lower upfront, higher risk |

Customization and options

Typical add-ons for the Black Seed Oil Expeller: 316 SS contact upgrade, VFD for fine-tuning torque, nitrogen blanketing on the receiving tank, plate-and-frame polishing filter, and food-grade gaskets. Some buyers request CIP-friendly fittings; doable with the right seal set.

Case in point

A boutique wellness brand near Ankara ran the HP120 at around 40 kg/h, seed moisture ~6.5%. Batch tests averaged FFA 1.2% (as oleic) and PV 3–4 meq O2/kg within 24 hours of pressing—solid for premium labeling. They liked the low noise and the fact that changeover to black cumin-coriander blends took under 20 minutes.

Compliance, testing, and support

Documentation typically includes CE conformity for machinery and ISO 9001-backed QC. For food safety programs (HACCP), processors align oil QA with AOCS/ISO methods and maintain traceability logs. Service-wise, users report responsive spare-part shipping and remote setup guidance—nothing fancy, just practical.

Bottom line: if you’re scaling from pilot to boutique production, the Black Seed Oil Expeller (HP120) hits that sweet spot—predictable, maintainable, and friendly to real-world operators who need clean oil without babying the machine all day.

Authoritative references

- AOCS Official Methods for Edible Oils (e.g., acid value, peroxide value). https://www.aocs.org

- ISO 660 (Acid value) and ISO 662 (Moisture & volatile matter) for fats and oils. https://www.iso.org

- Codex Alimentarius HACCP Guidelines (CAC/RCP 1-1969). https://www.fao.org/fao-who-codexalimentarius

- EU Machinery Directive 2006/42/EC, CE Conformity. https://eur-lex.europa.eu

-

Spiral Oil Press: Efficient Oil Extraction Technology for Sustainable Production

NewsNov.24,2025

-

Efficient Spiral Oil Expellers for Sustainable Oil Extraction | OilMill China

NewsNov.24,2025

-

Comprehensive Guide to Screw Physical Oil Expeller Technology & Benefits

NewsNov.23,2025

-

Durable and Efficient Screw Physical Oil Presses for Sustainable Oil Extraction

NewsNov.23,2025

-

Screw Oil Expeller – Efficient, Sustainable Mechanical Oil Extraction Solutions

NewsNov.22,2025

-

Comprehensive Guide to Cold Oil Expeller: Benefits, Uses & Future Trends

NewsNov.22,2025