அக் . 02, 2024 23:07 Back to list

Vegetable Oil Refinery Production and Processing Solutions for Efficient Manufacturing

Understanding the Vegetable Oil Refining Unit A Comprehensive Overview

The vegetable oil refining unit plays a crucial role in the production of edible oils, ensuring that these oils are not only safe for consumption but also of high quality and suitable for various culinary applications. The refining process involves a series of steps that remove impurities, enhance flavor, improve shelf life, and increase the overall nutritional value of the oil.

Process Overview

The refining of vegetable oils typically involves several key stages degumming, neutralization, bleaching, and deodorization

. Each of these stages is aimed at eliminating specific types of impurities and enhancing the oil’s quality.1. Degumming The first step in the refining process is degumming. Raw vegetable oils often contain phospholipids, which can cause cloudiness in the final product. During degumming, the oil is treated with water or an acid that helps remove these phospholipids. This is crucial, as it also enhances the oil's stability and prevents the formation of sediments.

2. Neutralization Following degumming, neutralization removes free fatty acids. These acids can lead to off-flavors and odors in the final product. In this step, an alkali solution (typically sodium hydroxide) is added to the oil, which reacts with the free fatty acids to form soap. The soap is then removed through centrifugation, leaving behind a more neutral, palatable oil.

3. Bleaching The bleaching step improves the color and clarity of the oil. The oil is treated with absorbent materials like activated carbon or bleaching earth, which adsorb pigments, trace metals, and other impurities. This stage not only improves the appearance of the oil but also further enhances its stability.

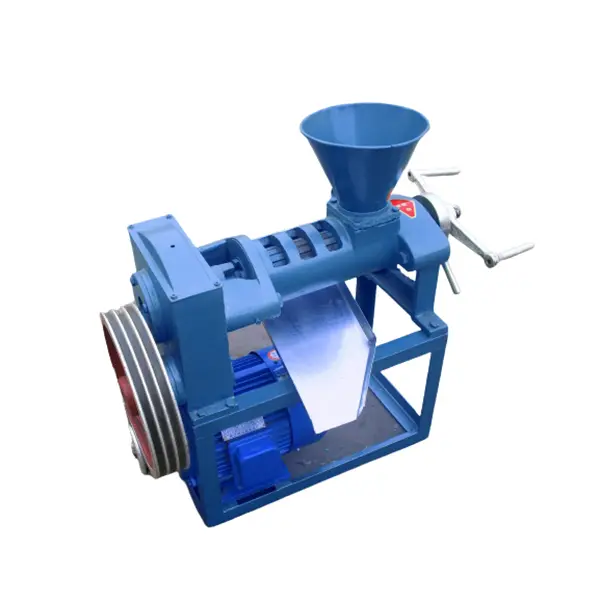

vegetable oil refining unit factory

4. Deodorization The final step in the refining process is deodorization, which removes volatile compounds responsible for undesirable odors and flavors. This is achieved by heating the oil under vacuum conditions. The heat, combined with the reduced pressure, allows volatile compounds to evaporate without significantly altering the oil's quality. The result is a neutral-tasting oil that is versatile in cooking and food preparation.

Quality Control and Standards

Throughout the refining process, quality control is paramount. Refined vegetable oils must meet specific standards set by regulatory bodies to ensure they are safe for consumer use. These standards focus on factors such as free fatty acid content, peroxide value, and the presence of contaminants. Regular testing and monitoring are essential to maintain the integrity of the final product.

Environmental Considerations

As awareness of environmental issues grows, the vegetable oil industry is increasingly focusing on sustainability. Many refining units are exploring eco-friendly practices, such as utilizing waste materials for biofuel production or implementing water recycling systems. These efforts not only help reduce the carbon footprint of the refining process but also contribute to the circular economy.

Conclusion

In conclusion, the vegetable oil refining unit is a vital component of the food production industry. By transforming crude oils into refined, high-quality products, these units ensure that consumers enjoy safe, nutritious, and flavorful oils. With ongoing advancements in technology and a commitment to sustainability, the vegetable oil refining industry is poised for a bright future, meeting both consumer demands and environmental responsibilities.

-

High-Efficiency Peanut Oil Refined Machine for Quality Oil Production Leading Exporters & Companies

NewsJul.08,2025

-

High Efficiency Sunflower Seed Oil Press – Leading Cooking Oil Press Machine Factories & Suppliers

NewsJul.08,2025

-

High-Efficiency Soybean Oil Press Machine – Leading Exporters & Reliable Companies

NewsJul.07,2025

-

High-Efficiency Seed to Oil Extractor – Reliable Extraction Machinery for Your Business

NewsJul.07,2025

-

High-Quality Pressing Screw of Oil Expeller for Efficient Oil Extraction Leading Exporters & Manufacturers

NewsJul.06,2025

-

High-Efficiency Essential Oil Extraction Machine Trusted Exporters & Companies

NewsJul.06,2025