Nov . 11, 2024 18:33 Back to list

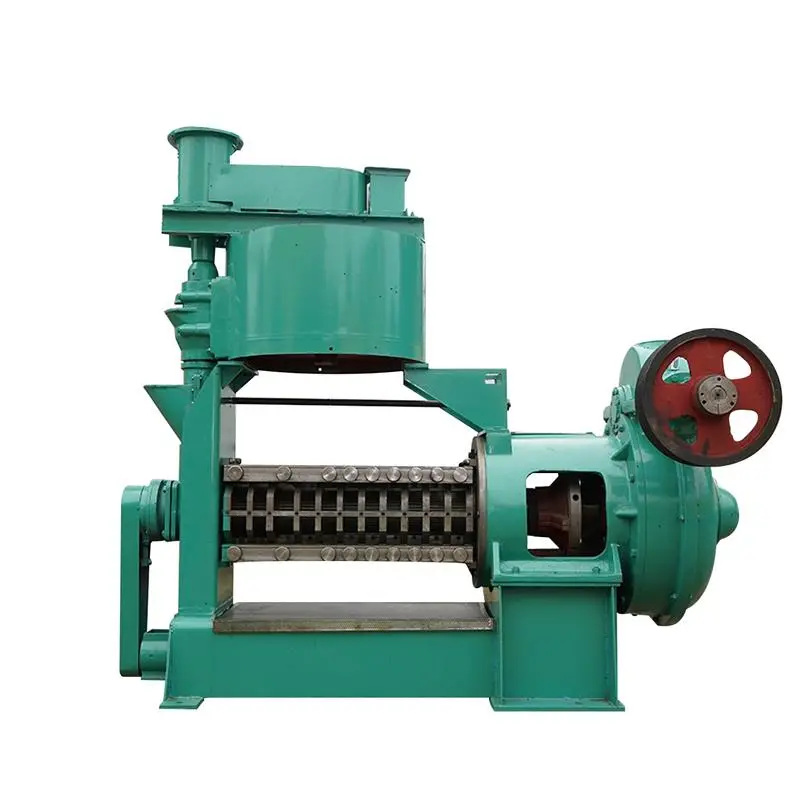

china safflower oil mill machinery

The Rise of Safflower Oil Production An Insight into China’s Safflower Oil Mill Machinery

In recent years, the demand for healthier cooking oils has prompted a significant rise in the production of safflower oil, particularly in China. Known for its light flavor and high smoke point, safflower oil is being preferred over other cooking oils due to its numerous health benefits, including heart-healthy properties and a wealth of unsaturated fats. As a result, the safflower oil milling industry has become an essential component of the agricultural and manufacturing sectors in the country. This article delves into the advancements in safflower oil mill machinery that are driving this growth.

The Importance of Safflower Oil

Safflower oil is extracted from the seeds of the safflower plant, which is known for its vibrant flowers and tolerance to arid conditions. The oil is rich in linoleic acid, a polyunsaturated fatty acid beneficial for cardiovascular health. In addition to cooking, safflower oil is increasingly used in salad dressings, margarine production, and various food products. Its nutritional advantages have led to a surge in consumer demand, prompting manufacturers to optimize their production processes.

Innovations in Safflower Oil Mill Machinery

As demand for safflower oil increases, the efficiency of oil milling machinery has become critical. Modern safflower oil mill machinery incorporates advanced technologies that optimize the extraction process, thus increasing yield while minimizing waste. Some of the key innovations include

1. Cold Pressing Technology Unlike traditional oil extraction methods that involve high heat, cold pressing retains more of the oil’s natural flavor and nutritional value. Modern cold-press machines leverage hydraulic and screw-press designs to efficiently extract oil while preserving its quality.

2. Solvent Extraction For larger production needs, solvent extraction remains an effective method. While it involves the use of solvents, advancements in machinery now ensure that oil is extracted efficiently, minimizing residual solvents in the final product.

china safflower oil mill machinery

3. Refining Equipment Once the oil is extracted, refining is necessary to remove impurities and ensure a longer shelf life. State-of-the-art refining equipment includes degumming, neutralization, bleaching, and deodorization processes, all of which are critical for producing high-quality safflower oil.

4. Automation and Control Systems The integration of automation in safflower oil mills has significantly improved productivity. Advanced control systems utilize sensors and software to monitor the extraction and refining processes in real time, allowing for precise adjustments and minimizing human error.

5. Sustainability Features With an increasing emphasis on environmental responsibility, many manufacturers are focusing on eco-friendly machinery that minimizes energy consumption and waste generation. For instance, energy-efficient machines and systems for reusing by-products are now commonplace in safflower oil mills.

Economic Significance

The growth of safflower oil production not only contributes to the agricultural economy but also supports rural development in China. As farmers embrace safflower cultivation due to its lucrative returns, job opportunities in milling and processing sectors continue to expand. Furthermore, as consumers become more health-conscious, the market for safflower oil grows, creating a ripple effect that benefits various stakeholders in the supply chain.

Conclusion

The surge in safflower oil production in China is a result of both health trends and advancements in mill machinery. As technology continues to evolve, safflower oil mill operations become more efficient, enabling producers to meet the growing consumer demands while ensuring high-quality output. In this rapidly evolving market landscape, embracing modern machinery and sustainable practices will be imperative for manufacturers looking to compete and thrive in the safflower oil industry. The future of safflower oil in China looks bright, with machinery innovations leading the way to new possibilities and extensive market growth opportunities.

-

Top Food Oil Refined Unit Companies w/ GPT-4 Turbo Tech

NewsAug.01,2025

-

Premium Black Seed Oil Expeller - High Efficiency Cold Press Oil Machine

NewsJul.31,2025

-

Oil Processing Equipment - High-Efficiency Flaking Machine

NewsJul.25,2025

-

High-Efficiency Peanut Oil Refined Machine for Quality Oil Production Leading Exporters & Companies

NewsJul.08,2025

-

High Efficiency Sunflower Seed Oil Press – Leading Cooking Oil Press Machine Factories & Suppliers

NewsJul.08,2025

-

High-Efficiency Soybean Oil Press Machine – Leading Exporters & Reliable Companies

NewsJul.07,2025