Dec . 19, 2024 01:37 Back to list

physical oil expeller factories

The Role of Physical Oil Expeller Factories in Modern Oil Processing

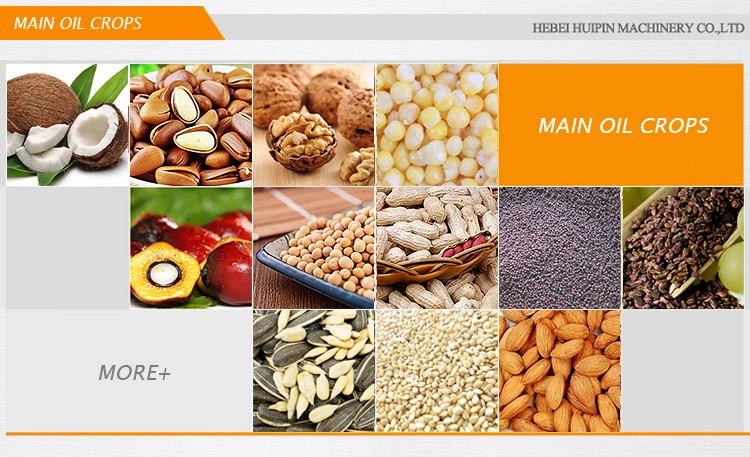

In today's rapidly evolving food industry, the demand for healthy and natural cooking oils continues to rise. This has led to significant advancements in oil extraction technologies, particularly in the realm of physical oil expellers. These factories, specializing in the extraction of edible oils from seeds and nuts, play a crucial role in ensuring the availability of high-quality oils while also adhering to consumer preferences for natural products.

Understanding Physical Oil Expellers

Physical oil expellers are mechanical devices used to extract oil from oilseeds through a physical process, primarily by applying mechanical pressure. Unlike chemical extraction methods, which often involve solvents and heat, physical expellers operate without the use of harsh chemicals. This process preserves the oil's natural properties, resulting in products that are often richer in flavor, nutrients, and aromatic compounds.

The operation of a physical oil expeller involves the crushing of oilseeds, followed by a pressing stage where the oil is extracted. The seed's natural oil content is released through compression, and the high temperatures generated during this process are kept within safe limits to prevent degradation of the oil. As a result, oils produced through physical processes retain a higher nutritional value, making them a preferred choice among health-conscious consumers.

The Importance of Oil Expeller Factories

Physical oil expeller factories are essential not only for producing high-quality oils but also for boosting local economies. These facilities often source their raw materials from local farmers, providing them with a stable income and promoting sustainable agricultural practices. By facilitating a direct link between producers and consumers, oil expeller factories foster community growth and empowerment.

Moreover, the emergence of these factories supports environmental sustainability. Many physical oil expellers use organic seeds and adhere to eco-friendly practices, reducing the reliance on chemical pesticides and fertilizers. This commitment to sustainability resonates with consumers increasingly concerned about the ecological impact of their food choices.

physical oil expeller factories

Technological Advancements

The oil processing industry is witnessing significant technological advancements, particularly in the design and efficiency of physical oil expellers. Many modern factories utilize automated systems that enhance production efficiency, reduce labor costs, and improve product consistency. Innovations such as cold-press extraction methods are also gaining traction, allowing for the production of oils at lower temperatures, which further retains their nutritional integrity.

In addition, advancements in filtration and refining technologies are enabling factories to produce oils that meet varying consumer needs and market standards. For instance, some consumers prefer unrefined oils for their robust flavor and health benefits, while others may opt for refined oils for cooking due to their higher smoke points. Physical oil expeller factories are adaptable, allowing them to cater to diverse market demands.

Challenges and Future Outlook

Despite the numerous benefits, physical oil expeller factories face challenges such as fluctuating raw material prices and competition from chemical extraction methods. As global demand for edible oils continues to rise, these factories must innovate continually to stay competitive. This may involve investing in research and development, exploring new markets, and educating consumers about the benefits of naturally extracted oils.

Looking ahead, the future of physical oil expeller factories appears promising. With increasing consumer awareness about health and sustainability, the demand for natural oils is expected to grow, providing opportunities for these factories to expand. Furthermore, the integration of biotechnology in oilseed cultivation could enhance yield and quality, further supporting the factories’ operations.

In conclusion, physical oil expeller factories are pivotal in the modern oil processing landscape. By producing high-quality, natural oils, they not only cater to consumer preferences but also contribute to sustainable agriculture and local economies. As the industry evolves, these factories remain at the forefront of innovation, shaping the future of edible oils for generations to come.

-

Sunflower Oil Seed Press Machine - High Efficiency, Durable & Cost-effective Extraction

NewsJun.24,2025

-

High-Efficiency Physical Oil Refining Unit - Leading Exporters & Trusted Companies

NewsJun.10,2025

-

High-Efficiency Animal Oil Refining Machine - Leading Exporters & Reliable Companies

NewsJun.10,2025

-

Camellia Oil Mill Machine for Efficient Oil Extraction Leading Exporters & Companies

NewsJun.10,2025

-

Premium Pressing Shaft for Oil Press Machines Exporters

NewsJun.10,2025

-

High-Efficiency Centrifugal Filters Durable Industrial Separation

NewsJun.10,2025