Ноя . 07, 2024 21:31 Back to list

Comprehensive Guide to Optimal Vegetable Oil Production Processes and Equipment

The Vegetable Oil Production Line A Comprehensive Overview

The production of vegetable oil is a crucial process in the food industry, driving the global market for cooking oils, margarine, and various food products. With a growing demand for healthy cooking options and plant-based products, the vegetable oil production line is more relevant than ever. This article explores the various stages involved in the vegetable oil production process, the machinery used, and the importance of sustainability in this industry.

Understanding the Vegetable Oil Production Process

The production of vegetable oil typically involves several key stages seed selection, extraction, refining, and packaging.

1. Seed Selection The journey begins with the careful selection of oilseeds, which can include soybeans, sunflowers, canola, palm, and others. The choice of seed plays a significant role in the oil's quality and nutritional value.

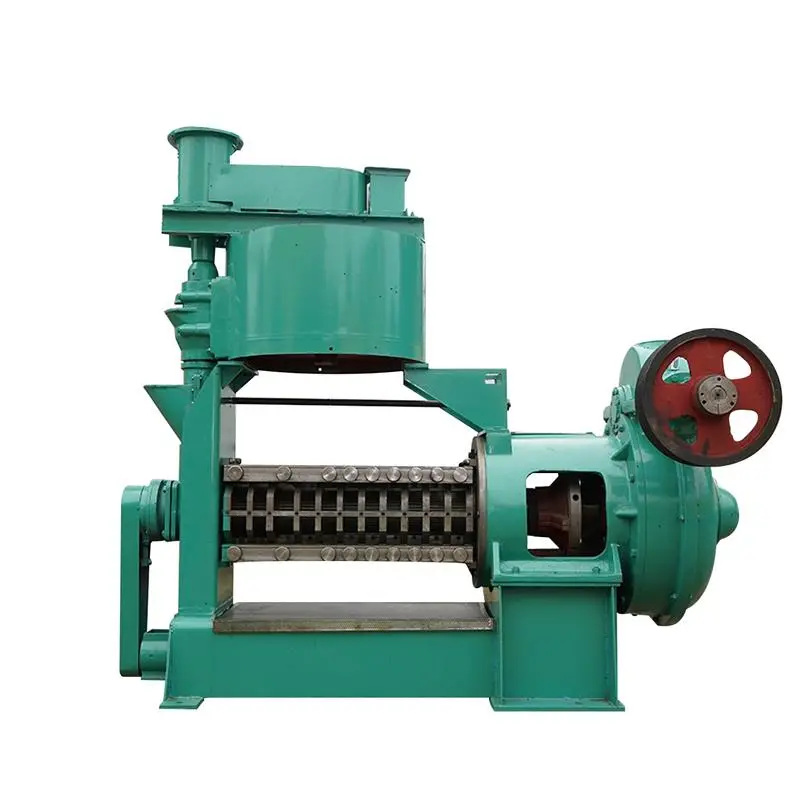

2. Oil Extraction This stage consists of two primary methods mechanical extraction and solvent extraction. Mechanical extraction involves pressing the seeds to extract oil, often using hydraulic or screw presses. Solvent extraction, on the other hand, utilizes organic solvents, such as hexane, which effectively dissolve oil from the seeds. The residual meals left after extraction can be used as animal feed, promoting a zero-waste approach.

3. Refining After extraction, the crude oil undergoes refining to remove impurities and improve flavor, color, and shelf life. The refining process consists of several steps, including degumming, neutralization, bleaching, and deodorization. Degumming removes phospholipids, while neutralization eliminates free fatty acids. Bleaching involves removing color pigments, and deodorization eliminates any undesirable odors. Each step is crucial for producing a high-quality oil that meets consumer standards.

4. Packaging Once refined, the vegetable oil is tested for quality before being packaged. Packaging is an essential aspect, as it protects the oil from oxidation and contamination, ensuring it remains fresh for consumers. Various packaging materials are employed, from glass bottles to plastic containers, depending on market needs and environmental considerations.

Machinery in the Vegetable Oil Production Line

The vegetable oil production line is equipped with specialized machinery designed to optimize the extraction and refining processes. Key machinery includes

- Seed Cleaning Equipment This machinery cleans the raw seeds to remove dust, husks, and impurities before processing. - Oil Presses Both screw and hydraulic presses are widely used in the mechanical extraction phase, separating oil from seeds efficiently.

vegetable oil production line

- Solvent Extraction Units These units utilize various approaches to ensure maximum oil recovery through solvent extraction.

- Refining Equipment This includes neutralizers, bleachers, and deodorizers, each tailored to specific refining needs

.- Filling and Packaging Machines Automated systems that fill and seal containers ensure speedy and hygienic packaging, readying the oil for distribution.

The Importance of Sustainability

As the world increasingly prioritizes sustainable practices, the vegetable oil industry is no exception. Unsustainable palm oil production has garnered significant attention due to its impact on deforestation and biodiversity. Consequently, many producers now seek to adopt environmentally friendly practices such as

- Certifications Obtaining certifications like the Roundtable on Sustainable Palm Oil (RSPO) helps ensure that producers adhere to sustainable practices that protect ecosystems and support local communities.

- Waste Minimization Innovations in production lines have led to better waste management and the utilization of byproducts. For example, leftover seed meals can be repurposed as animal feed or biofuel, reducing waste and maximizing resource efficiency.

- Water and Energy Use Modern vegetable oil production lines are designed to minimize water and energy consumption, employing closed-loop systems and renewable energy sources.

Conclusion

The vegetable oil production line represents an intricate blend of traditional practices and modern technology, contributing to the global food supply while addressing the need for sustainability. As consumers become increasingly aware of the environmental impact of their choices, the industry must continue to evolve, ensuring that its practices are environmentally responsible and promote long-term sustainability. With ongoing advancements in technology and a growing commitment to ethical production, the future of vegetable oil production looks promising, balancing quality and sustainability to meet the needs of consumers worldwide.

-

Top Food Oil Refined Unit Companies w/ GPT-4 Turbo Tech

NewsAug.01,2025

-

Premium Black Seed Oil Expeller - High Efficiency Cold Press Oil Machine

NewsJul.31,2025

-

Oil Processing Equipment - High-Efficiency Flaking Machine

NewsJul.25,2025

-

High-Efficiency Peanut Oil Refined Machine for Quality Oil Production Leading Exporters & Companies

NewsJul.08,2025

-

High Efficiency Sunflower Seed Oil Press – Leading Cooking Oil Press Machine Factories & Suppliers

NewsJul.08,2025

-

High-Efficiency Soybean Oil Press Machine – Leading Exporters & Reliable Companies

NewsJul.07,2025