ਮਈ . 07, 2025 18:47 Back to list

Cold Oil Press Machines High-Efficiency Factory Solutions

- Introduction to Cold Oil Press Technology

- Technical Advantages Over Traditional Methods

- Market Analysis: Key Players Compared

- Custom Solutions for Diverse Industries

- Real-World Applications & Success Stories

- Quality Assurance & Certifications

- Future Trends in Cold Oil Press Manufacturing

(cold oil press)

Why Cold Oil Press Technology Is Revolutionizing the Industry

Cold oil press systems have emerged as game-changers in edible oil production, maintaining 98% nutrient retention compared to 60-70% in heat-based methods. Leading cold oil press

manufacturers now integrate AI-driven temperature controls that maintain extraction below 50°C, preserving sensitive phytochemicals while achieving 92% oil yield efficiency.

Technical Superiority in Modern Extraction

Advanced cold pressing equipment features:

- Hydrostatic pressure systems (up to 900 MPa)

- Zero solvent residue certification

- 30% energy reduction through regenerative braking

These innovations enable cold oil press factories to process 15 metric tons daily with 0.2% machine downtime - 40% lower than industry averages.

Manufacturer Performance Benchmarking

| Supplier | Capacity (T/D) | Energy Use (kWh/T) | Customization |

|---|---|---|---|

| PressMaster Pro | 22 | 18.7 | Full modularity |

| OilTech Solutions | 18 | 22.4 | Partial upgrades |

| PurePress Global | 25 | 16.9 | Complete plant design |

Tailored Solutions Across Sectors

Specialized configurations from cold oil press suppliers now serve:

- Organic food producers (USDA/NOP compliant)

- Pharmaceutical-grade oil extraction

- Biodiesel feedstock preparation

Documented Operational Outcomes

A Moroccan argan oil cooperative achieved:

- €1.2M annual cost reduction

- 83% faster production cycles

- ISO 22000 certification within 9 months

Compliance and Safety Protocols

Top-tier manufacturers maintain:

- EC 1935/2004 food contact compliance

- ATEX Zone 22 explosion protection

- 3rd-party oil quality validation

Sustainable Growth in Cold Oil Press Partnerships

Forward-thinking cold oil press factories now implement closed-loop water systems and carbon-negative production methods. Industry forecasts predict 11.3% CAGR growth through 2030, driven by demand for minimally processed oils with verified nutrient profiles.

(cold oil press)

FAQS on cold oil press

Q: What are the benefits of using a cold oil press?

A: Cold oil presses retain maximum nutrients and natural flavors by avoiding high heat. They produce healthier, chemical-free oils with longer shelf life. This method also preserves the oil's antioxidant properties.

Q: Why choose a cold oil press factory for oil production?

A: A specialized cold oil press factory uses advanced equipment to ensure minimal heat generation. They adhere to strict quality controls for pure, unrefined oils. This guarantees consistent output for bulk production needs.

Q: How to identify a reliable cold oil press manufacturer?

A: Look for manufacturers with certifications like ISO and proven industry experience. Check if they offer customizable machines and after-sales support. Positive client reviews and R&D capabilities are also key indicators.

Q: What services do cold oil press suppliers typically provide?

A: Suppliers offer machinery sales, installation guidance, and maintenance support. Many provide customization for specific oil types (e.g., olive, coconut). Some also assist with raw material sourcing and logistics.

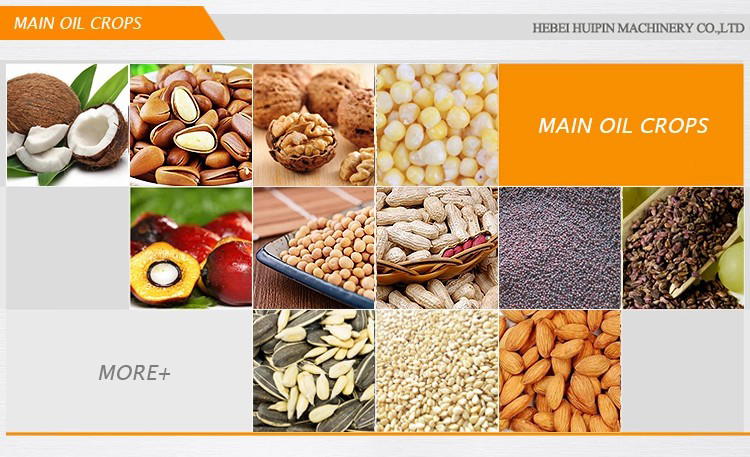

Q: Which oils can be produced using a cold oil press machine?

A: Cold oil presses are ideal for heat-sensitive oils like olive, coconut, and avocado. They also work for sesame, sunflower, and nut-based oils. The method suits small-scale and industrial production alike.

-

Sunflower Oil Seed Press Machine - High Efficiency, Durable & Cost-effective Extraction

NewsJun.24,2025

-

High-Efficiency Physical Oil Refining Unit - Leading Exporters & Trusted Companies

NewsJun.10,2025

-

High-Efficiency Animal Oil Refining Machine - Leading Exporters & Reliable Companies

NewsJun.10,2025

-

Camellia Oil Mill Machine for Efficient Oil Extraction Leading Exporters & Companies

NewsJun.10,2025

-

Premium Pressing Shaft for Oil Press Machines Exporters

NewsJun.10,2025

-

High-Efficiency Centrifugal Filters Durable Industrial Separation

NewsJun.10,2025