Nov . 27, 2024 01:43 Back to list

OEM Hot Press Oil Extraction Machine for Efficient Oil Production

The Importance and Efficiency of OEM Hot Press Oil Machines in Modern Oil Extraction

In today’s rapidly evolving agricultural and manufacturing sectors, the demand for efficient oil extraction techniques has surged. Among various methods available, hot press oil machines, specifically those that are OEM (Original Equipment Manufacturer), have gained significant attention for their efficiency, reliability, and versatility. This article will explore the mechanisms, advantages, and applications of OEM hot press oil machines in oil extraction processes.

Understanding Hot Press Oil Machines

Hot press oil machines utilize elevated temperatures to extract oil from various seeds and nuts, such as sunflower seeds, soybeans, and peanuts. The process involves heating the raw materials, which helps to soften the oil-bearing constituents, and then applying mechanical pressure to extract the oil. The effectiveness of this method lies in the combination of heat and pressure, leading to a higher oil yield compared to cold-press methods.

In the context of OEM hot press oil machines, these are specifically designed by manufacturers to meet distinct requirements of clients, often incorporating advanced technology and customizable features. This ensures that the machines can efficiently manage different types of raw materials while optimizing the extraction process.

Advantages of OEM Hot Press Oil Machines

1. High Oil Yield One of the most notable benefits of using OEM hot press oil machines is the higher oil extraction rate. The application of heat makes the oil more fluid, allowing for a more efficient extraction process. This means producers can maximize their output, translating to better profitability.

2. Customization OEM manufacturers often provide tailored solutions, allowing clients to modify machines according to their specific needs. This includes adjustments to size, capacity, and heating mechanisms, ensuring that the machines fit seamlessly into existing production lines.

3. Efficiency These machines are engineered for high performance, often featuring advanced automation and monitoring systems. This enhances operational efficiency, reduces labor costs, and minimizes human error during the oil extraction process.

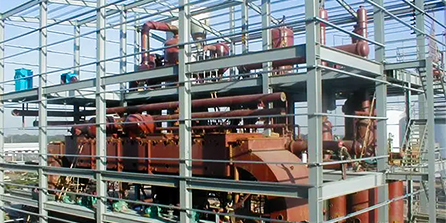

oem hot press oil machine

4. Quality of Oil The heating process in hot press oil extraction not only enhances yield but can also improve the quality of the oil. The controlled temperature helps to retain flavors and nutrients, resulting in a superior product that is more appealing in the food and cosmetics industries.

5. Versatility OEM hot press oil machines can be used for extracting oil from a wide array of seeds and nuts. This flexibility makes them valuable assets for businesses that wish to diversify their product offerings without investing in multiple types of extraction equipment.

Applications of OEM Hot Press Oil Machines

The application of OEM hot press oil machines is vast, spanning various industries

- Food Industry In food production, hot press oil machines are extensively used to extract cooking oils and essential oils. High-quality oils are crucial for flavor and nutrition, making these machines indispensable for food manufacturers.

- Cosmetics and Personal Care Oil extraction is a significant part of producing cosmetic products, as natural oils serve as emollients and active ingredients. Hot press oil machines ensure that high-quality oils are obtained, contributing to better product formulations.

- Biodiesel Production With the increasing emphasis on renewable energy sources, hot press oil machines are also utilized in the production of biodiesel. The extracted oils can serve as feedstock for biodiesel, aligning with sustainability efforts.

Conclusion

In conclusion, OEM hot press oil machines represent a fundamental innovation in the oil extraction industry. Their ability to deliver higher yields, enhanced oil quality, and the flexibility to adapt to various raw materials makes them an essential tool for manufacturers. As the demand for quality oils continues to rise in food production, cosmetics, and renewable energy sectors, the investment in advanced and customized hot press oil machines stands to benefit producers significantly. Embracing these technologies not only drives productivity but also ensures that companies remain competitive in an ever-changing market landscape. Thus, the future of oil extraction hinges on the continuous development of these sophisticated machines.

-

High-Efficiency Physical Oil Refining Unit - Leading Exporters & Trusted Companies

NewsJun.10,2025

-

High-Efficiency Animal Oil Refining Machine - Leading Exporters & Reliable Companies

NewsJun.10,2025

-

Camellia Oil Mill Machine for Efficient Oil Extraction Leading Exporters & Companies

NewsJun.10,2025

-

Premium Pressing Shaft for Oil Press Machines Exporters

NewsJun.10,2025

-

High-Efficiency Centrifugal Filters Durable Industrial Separation

NewsJun.10,2025

-

Top Neem Seed Oil Press - Efficient, High-Yield Extraction Solutions

NewsJun.09,2025