Sep . 16, 2024 12:38 Back to list

Wholesale Grain Oil Refining Unit - Quality Edible Oils for Wholesale Distribution

The Wholesale Grain Oil Refining Unit A Critical Component of the Food Industry

The wholesale grain oil refining unit plays a pivotal role in the food industry, serving as a crucial intermediary between raw agricultural products and the consumer market. This unit is responsible for transforming crude vegetable oils, derived from grains and oilseeds, into refined oils that meet the safety, quality, and regulatory standards required for consumption and cooking. Understanding the complexities and importance of this unit is essential for comprehending the larger food supply chain.

At the core of the refining process are oilseeds such as soybeans, sunflowers, and canola. These seeds undergo several stages of processing before reaching the wholesale refining unit. Initially, seeds are cleaned, cracked, and cooked to extract the crude oil, which contains impurities, color pigments, and free fatty acids that are undesirable for consumption. The crude oil then undergoes a series of refining steps, including degumming, neutralization, bleaching, and deodorization.

Degumming is the first stage, where phospholipids and other hydrophilic impurities are removed. This step is crucial because it prevents the formation of undesirable substances during storage and enhances the oil's quality. Following this, neutralization is employed to eliminate free fatty acids through the addition of alkali, producing a more palatable oil. After neutralization, the oil is bleached to remove color pigments and other impurities, ensuring that the final product is visually appealing to consumers. Finally, deodorization is performed using steam distillation to eliminate any remaining odors, resulting in a neutral-tasting oil that appeals to a wide range of culinary applications.

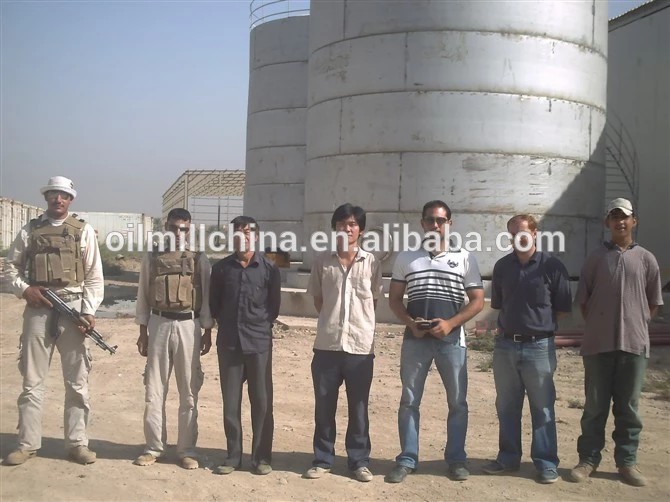

wholesale grain oil refining unit

The wholesale grain oil refining unit must adhere to strict regulatory standards to ensure food safety. Various national and international guidelines dictate acceptable levels of contaminants and the necessary hygiene measures throughout the refining process. The implementation of Hazard Analysis and Critical Control Points (HACCP) systems is common practice within these units, allowing for the identification and management of potential risks associated with oil processing.

Additionally, advancements in technology have significantly improved the efficiency and sustainability of the refining process. Modern refining units are increasingly adopting environmentally friendly practices, such as waste reduction and energy recovery systems, to minimize their ecological footprint. By implementing these practices, the industry not only contributes to environmental conservation but also enhances the overall economic feasibility of oil production.

As consumer preferences evolve towards healthier options, the wholesale grain oil refining unit is also adapting to meet these new demands. There is a growing trend towards producing oils with specific health benefits, such as those high in omega-3 fatty acids or low in saturated fats. This shift is driving innovation within the sector, compelling refiners to invest in research and development to diversify their product offerings.

In conclusion, wholesale grain oil refining units are integral to transforming raw commodities into safe, high-quality cooking oils. Through rigorous processing, adherence to regulatory standards, and the adoption of innovative practices, these units ensure that the food supply chain remains efficient and responsive to consumer needs. As the industry continues to evolve, the refining unit will undoubtedly play a crucial role in shaping the future of food production.

-

HP 120 Cold Oil Press - Hebei Huipin Machinery | Oil Extraction, Automation

NewsAug.06,2025

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery Co., LTD | Labor-Saving, Multi-Functional

NewsAug.06,2025

-

HP 120 Cold Oil Press - Hebei Huipin | Oil Extraction, High Efficiency

NewsAug.06,2025

-

HP 120 Cold Oil Press - Hebei Huipin | High Efficiency & Versatility

NewsAug.06,2025

-

Durable & High Yield Industrial Soy Bean Oil Press Machine

NewsAug.06,2025

-

Commercial High-Efficiency Oil Expeller Press

NewsAug.05,2025