Dec . 23, 2024 09:35 Back to list

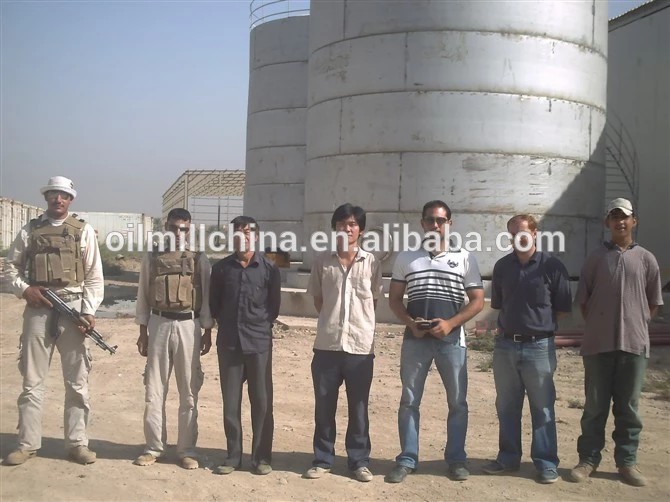

sunflower oil making machine pressing

The Process of Sunflower Oil Extraction Understanding the Sunflower Oil Making Machine

Sunflower oil, renowned for its light flavor and high smoke point, is a popular cooking oil around the globe. Extracting this beneficial oil involves a systematic approach, primarily utilizing sunflower oil making machines specifically designed for pressing seeds. This article will explore the pressing process, including the machinery involved, and the benefits of sunflower oil.

The Importance of Sunflower Oil

Sunflower oil is rich in vitamin E and low in saturated fats, making it a healthier alternative to many other cooking oils. It is widely used not only for cooking but also in cosmetics, as an ingredient in salad dressings, and as a base for frying various dishes. Given its popularity, the sunflower oil extraction process has become a lucrative business venture in many agricultural regions.

The Sunflower Seed

Before delving into the pressing process, it is crucial to understand the sunflower seed itself. Sunflower seeds are harvested from the sunflower plant (Helianthus annuus), which thrives in warm climates. The seeds are high in oil content, ranging from 40% to 60%, depending on the variety and conditions under which they were grown.

The Pressing Process

The extraction of sunflower oil primarily occurs through the pressing method, which can be divided into several stages

1. Seed Preparation Once harvested, the sunflower seeds must be cleaned and prepared for oil extraction. This involves removing any impurities, such as dirt and foreign particles, to ensure high-quality oil. The seeds may also be heated slightly to help increase oil yield during pressing.

sunflower oil making machine pressing

2. Crushing The prepared seeds are then crushed mechanically. This operation is often conducted using a sunflower oil making machine equipped with a hammer mill or expeller. The crushing process breaks the seeds into smaller pieces, allowing for more effective oil extraction.

3. Pressing After crushing, the next step involves using a mechanical press to extract the oil. There are two types of pressing methods commonly employed cold and hot pressing. Cold pressing is performed without any added heat, which preserves the nutrients and flavor of the oil. In contrast, hot pressing involves heating the seeds before extraction, which can increase the oil yield but may also alter some of the oil's properties.

4. Filtration Once the oil is extracted, it is typically cloudy due to the presence of seed particles. Filtration is necessary to remove these impurities, resulting in a clearer and more aesthetically pleasing product. This step may involve the use of filters or centrifuges.

5. Degumming and Refining The extracted oil may undergo further refining processes to remove any remaining impurities and to improve its flavor, color, and shelf stability. This step can include degumming, bleaching, and deodorization, which are critical for enhancing the quality of the final product.

6. Packaging The final stage in the sunflower oil processing involves packaging. The oil is stored in clean, sterilized containers to maintain its freshness and prevent contamination. Proper labeling and storage also help in marketing the oil effectively.

The Role of Machinery

Sunflower oil making machines play a pivotal role in the pressing process. Advanced technologies have led to the development of efficient oil extraction machines that optimize oil yield while minimizing waste. Modern machinery is often equipped with digital monitoring systems, enabling precise control over temperature, pressure, and speed during the extraction process. As a result, manufacturers can produce high-quality sunflower oil consistently.

Conclusion

The sunflower oil making machine is an essential tool in the production of one of the world's favorite cooking oils. Understanding the pressing process provides valuable insights into how sunflower oil is extracted and processed. From seed preparation to the final packaging, each step is crucial in ensuring the quality and taste of the oil. As consumers increasingly seek healthier cooking options, the demand for sunflower oil, along with efficient production methods, will continue to grow. Investing in modern sunflower oil extraction technology not only supports the production of high-quality oil but also contributes positively to the agricultural economy.

-

Leading Food Oil Refined Unit Companies | Quality & Efficient Solutions

NewsAug.27,2025

-

Expert Food Oil Refined Unit Companies | Advanced & Efficient Refining

NewsAug.26,2025

-

Food Oil Refined Machine Companies: High-Efficiency Oil Refining

NewsAug.25,2025

-

Popular Commercial Oilseed Crushing Machinery | High-Yield Oil Expeller Press

NewsAug.24,2025

-

Food Oil Refined Unit Companies: Leading Manufacturers & Exporters

NewsAug.23,2025

-

Expert Oil Filter Machine Service & Solutions | Quality & Reliability

NewsAug.22,2025