Oct . 22, 2024 14:47 Back to list

Small Edible Oil Refinery Plant Products and Their Applications in Culinary Use

Small Edible Oil Refinery Plant Products A Comprehensive Overview

Edible oil is an essential ingredient in many cuisines worldwide. As the demand for high-quality cooking oils continues to rise, small edible oil refinery plants have emerged as crucial players in the food processing industry. These micro or small-scale refineries are primarily designed to extract and refine oil from various seeds and nuts, producing a range of products that cater to diverse consumer needs. This article will explore the various products generated by small edible oil refinery plants, their significance, and the processes involved in creating them.

The Refining Process

Before delving into the products, it is essential to understand the basic refining process. Small edible oil refineries typically follow a multi-step approach

1. Oil Extraction The first step involves extracting oil from raw materials, which can include sunflower seeds, soybean, palm fruits, and canola. Techniques such as cold pressing or solvent extraction are commonly employed to obtain crude oil.

2. Degumming The crude oil contains impurities, including phospholipids, that need to be removed. Degumming is the process of treating the oil with water or acid to separate these impurities.

3. Neutralization This step is crucial for removing free fatty acids, which can adversely affect the oil's flavor and shelf life. Caustic soda is often used for this neutralization process.

4. Bleaching Bleaching involves removing pigments and other unwanted materials to enhance the color of the oil. Adsorbents such as activated clay are widely used in this stage.

5. Deodorization This final step removes any volatile compounds that may affect the oil's odor and taste. The oil is heated to high temperatures under a vacuum, ensuring a neutral flavor profile.

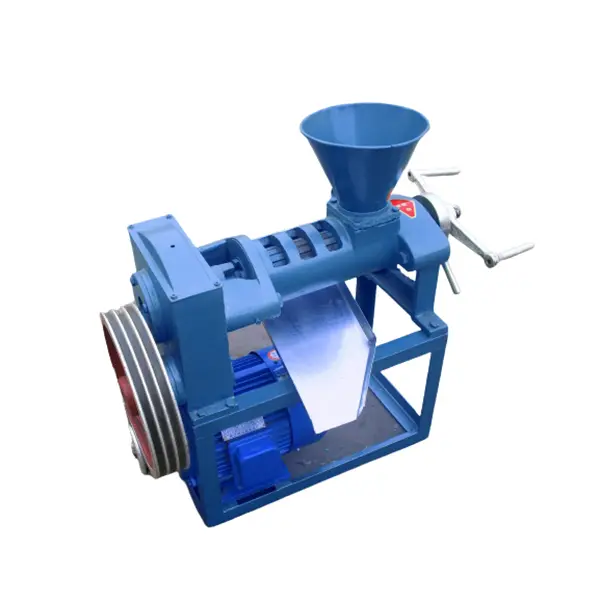

small edible oil refinery plant products

Products of Small Edible Oil Refineries

After undergoing the refining process, small edible oil refineries can produce a variety of products, which can be categorized as follows

1. Refined Cooking Oils The primary product of any edible oil refinery is refined cooking oils. This encompasses a range of oils such as sunflower oil, soybean oil, palm oil, canola oil, and more. Each type has specific culinary uses and health benefits, catering to different dietary preferences.

2. Oil Blends Many consumers prefer blended oils that combine the benefits of various types of oils. Small refineries can create customized oil blends, allowing them to target various markets and consumer preferences.

3. By-products The refining process also produces several by-products, including - Glycerin A valuable compound used in food, cosmetics, and pharmaceuticals. It can be sold or utilized in other production processes. - Oil Cakes The residual cakes left after oil extraction from seeds can be used as animal feed or as ingredients for organic fertilizers.

4. Organic Oils With a growing trend towards health-conscious eating, many small edible oil refineries are now producing organic oils. Sourced from organically grown seeds, these products attract consumers looking for healthier and environmentally friendly options.

5. Specialty Oils These are less common and often produced in smaller quantities but can provide high margins. Examples include sesame oil, flaxseed oil, and avocado oil, which offer unique flavors and health benefits.

Conclusion

Small edible oil refinery plants play a pivotal role in the food industry by providing a diverse array of products that cater to various culinary and health-oriented preferences. With ongoing advancements in refining technology, these plants can ensure high-quality outputs while minimizing waste through the use of by-products. As consumer trends shift towards healthier and more sustainable options, the potential for small edible oil refineries to innovate and thrive remains vast. The focus on quality, sustainability, and customization will likely define the future of edible oil production in the small-scale sector.

-

HP 120 Cold Oil Press-Hebei Huipin|Efficient Extraction&Multi-Use

NewsAug.16,2025

-

HP 120 Cold Oil Press-Hebei Huipin|High-Efficiency Oil Extraction&Cold Press Technology

NewsAug.16,2025

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery | High Efficiency Oil Extraction Machine

NewsAug.16,2025

-

Food Oil Refined Machines: Quality & Efficient Oil Refining

NewsAug.16,2025

-

HP 120 Cold Oil Press - Hebei Huipin Machinery|Oil Extraction&Efficiency

NewsAug.15,2025

-

HP 120 Cold Oil Press - Hebei Huipin Machinery | Automated Oil Extraction&High Efficiency

NewsAug.15,2025