Aug . 13, 2024 06:22 Back to list

Refined Mustard Oil Processing Equipment for Efficient Production and Quality Enhancement

The Importance of Refined Mustard Oil and Production Machinery

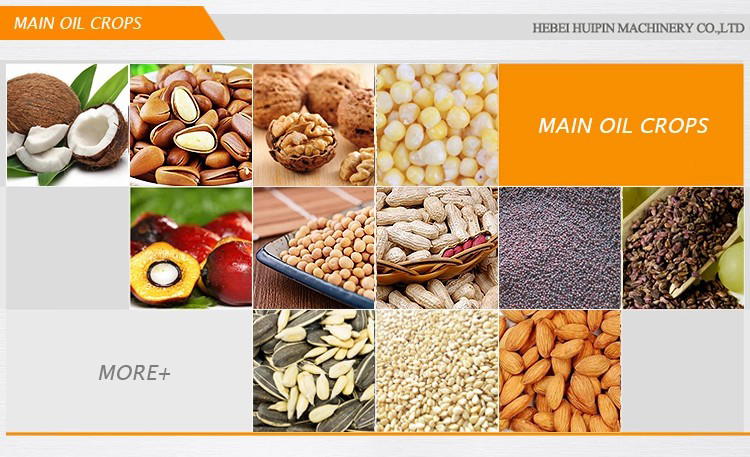

Mustard oil has long been a staple in households around the world, particularly in South Asia. Known for its pungent flavor and numerous health benefits, it has gained popularity not only as a culinary oil but also for its therapeutic properties. The extraction and refinement of mustard oil are essential processes that involve advanced machinery, ensuring that the final product meets quality standards and consumer demands.

Refined mustard oil is extracted from the seeds of the mustard plant, primarily Brassica juncea. The extraction process can be achieved through several methods, including cold pressing and solvent extraction. However, for commercial purposes, the refined version is often preferred due to its higher shelf life, stability, and neutral flavor. The refining process removes impurities, free fatty acids, and strong odors, resulting in a oil that is clearer, lighter, and more appealing for cooking.

The Importance of Refined Mustard Oil and Production Machinery

1. Seed Cleaning Machines Before the oil is extracted, mustard seeds must be thoroughly cleaned to remove any dirt, stones, or foreign materials. This is where seed cleaning machines come into play. These machines utilize various processes such as screening, air classification, and gravity separation to ensure that only pure mustard seeds are processed.

famous mustard oil refined machine

2. Oil Expellers Once the seeds are cleaned, they are fed into oil expellers for extraction. This machine uses mechanical pressure to extract oil from the seeds. Cold-pressed oil is extracted at lower temperatures, preserving the oil's natural flavor and nutritional properties, while hot-pressed methods produce higher yields. Depending on the requirements, manufacturers choose the appropriate type of expeller.

3. Refining Units After extraction, raw mustard oil contains impurities that need to be removed to make it suitable for consumption. The refining units employ processes such as degumming, neutralization, bleaching, and deodorization. This multifaceted approach ensures that the oil meets safety regulations and has an extended shelf life. Each step in the refining process is critical, as it enhances the oil's quality, flavor, and aroma.

4. Packaging Machines Once the oil is refined, it must be packaged properly to ensure its quality is maintained during storage and transportation. Advanced packaging machines help in bottling, labeling, and sealing the oil efficiently. Proper packaging is vital, as it protects the oil from environmental factors like light and air that can lead to oxidation and spoilage.

The production of refined mustard oil not only meets the culinary needs of consumers but also has a significant economic impact. The mustard oil industry provides employment opportunities in farming, processing, and distribution sectors. Additionally, the demand for mustard oil is on the rise globally due to its perceived health benefits, such as heart health promotion and anti-inflammatory properties.

In conclusion, the machinery used in the production of refined mustard oil is essential for ensuring quality and efficiency in the process. As the demand for this versatile oil continues to grow, investing in advanced production technology becomes increasingly important. This investment not only enhances the quality of mustard oil but also contributes to the overall economic development of regions reliant on mustard farming and oil production.

-

Safflower Oil Press Service: Efficient & Quality Extraction

NewsAug.18,2025

-

HP 120 Cold Oil Press-Hebei Huipin Machinery|Oil Extraction, High Efficiency

NewsAug.17,2025

-

HP 120 Cold Oil Press - Hebei Huipin Machinery | High-Efficiency Oil Extraction

NewsAug.17,2025

-

HP 120 Model Cold Oil Press-Hebei Huipin Machinery|Oil Extraction, Cold Press

NewsAug.17,2025

-

HP 120 Cold Oil Press-Hebei Huipin Machinery|Oil Extraction, Cold Press Machine

NewsAug.17,2025

-

HP 120 Cold Oil Press-Hebei Huipin Machinery|Oil Extraction, Cold Pressing

NewsAug.17,2025