Jan . 09, 2025 10:56 Back to list

flaxseed oil press

In the evolving landscape of oil extraction, the oil press machine stands as a cornerstone technology for small-scale producers and industrial manufacturers alike. Grasping the intricacies of this technology can significantly benefit those in various oil-pursuing industries, from food production to alternative energy sectors.

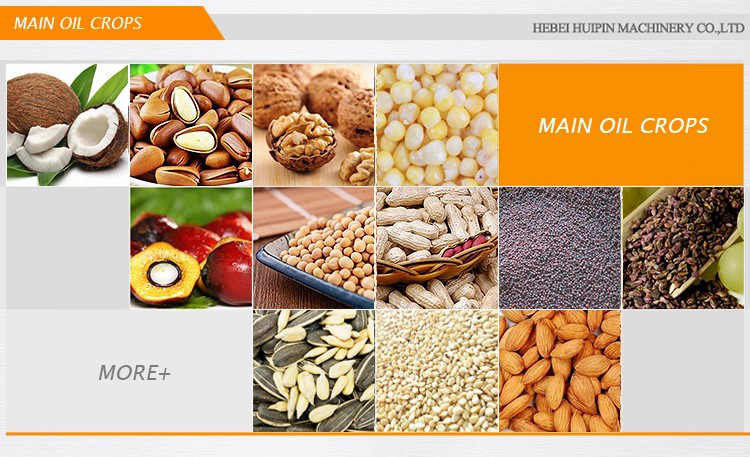

Equipping oneself with deeper knowledge about specific crop requirements can further hone the output quality. Different seeds and nuts contain varying oil percentages and hardness levels, demanding tailored pressing techniques. Expertise in these details allows operators to adjust machine settings, optimizing pressure and heat levels to suit each type of material. Such precision not only enhances oil recovery rates but also minimizes wastage, aligning with sustainable practices favored in modern production standards. Moreover, the evolving market trends towards organic and pure oils have amplified attention on the transparency and trustworthiness of production methods. Producers employing oil press machines find themselves in a favorable position to meet consumer demands for traceable, high-quality products. Establishing a reliable operation, documented with certifications and quality checks, supports credibility and brand authority in the marketplace. For those venturing into the oil pressing industry, aligning with authoritative voices and standards is recommended. Engaging with industry forums, attending workshops, and consulting with seasoned professionals can provide invaluable insights and keep operators informed about the latest advancements and safety protocols. In summation, mastering the oil press machine involves a blend of practical experience, technical expertise, and adherence to credible practices. By understanding the nuances of different machine types, performing diligent maintenance, and aligning production with market and regulatory standards, one can leverage this machinery to achieve substantial and sustainable success in the oil extraction industry.

Equipping oneself with deeper knowledge about specific crop requirements can further hone the output quality. Different seeds and nuts contain varying oil percentages and hardness levels, demanding tailored pressing techniques. Expertise in these details allows operators to adjust machine settings, optimizing pressure and heat levels to suit each type of material. Such precision not only enhances oil recovery rates but also minimizes wastage, aligning with sustainable practices favored in modern production standards. Moreover, the evolving market trends towards organic and pure oils have amplified attention on the transparency and trustworthiness of production methods. Producers employing oil press machines find themselves in a favorable position to meet consumer demands for traceable, high-quality products. Establishing a reliable operation, documented with certifications and quality checks, supports credibility and brand authority in the marketplace. For those venturing into the oil pressing industry, aligning with authoritative voices and standards is recommended. Engaging with industry forums, attending workshops, and consulting with seasoned professionals can provide invaluable insights and keep operators informed about the latest advancements and safety protocols. In summation, mastering the oil press machine involves a blend of practical experience, technical expertise, and adherence to credible practices. By understanding the nuances of different machine types, performing diligent maintenance, and aligning production with market and regulatory standards, one can leverage this machinery to achieve substantial and sustainable success in the oil extraction industry.

Latest news

-

Leading Food Oil Refined Unit Companies | Quality & Efficient Solutions

NewsAug.27,2025

-

Expert Food Oil Refined Unit Companies | Advanced & Efficient Refining

NewsAug.26,2025

-

Food Oil Refined Machine Companies: High-Efficiency Oil Refining

NewsAug.25,2025

-

Popular Commercial Oilseed Crushing Machinery | High-Yield Oil Expeller Press

NewsAug.24,2025

-

Food Oil Refined Unit Companies: Leading Manufacturers & Exporters

NewsAug.23,2025

-

Expert Oil Filter Machine Service & Solutions | Quality & Reliability

NewsAug.22,2025