Dec . 24, 2024 19:11 Back to list

Essential Services for Oil Mill Machine Accessories and Maintenance Solutions

The Importance of Accessory Services for Oil Mill Machines

In the modern agricultural landscape, oil extraction has become a vital sector, providing essential oils that are used in cooking, cosmetics, and industrial applications. For operational efficiency and productivity, oil mill machines play a critical role in this process. However, the performance of these machines can be significantly enhanced through the use of quality accessories and regular servicing. This article discusses the importance of oil mill machine accessories, the types of accessories available, and the role of service in ensuring smooth operation.

Understanding Oil Mill Machines

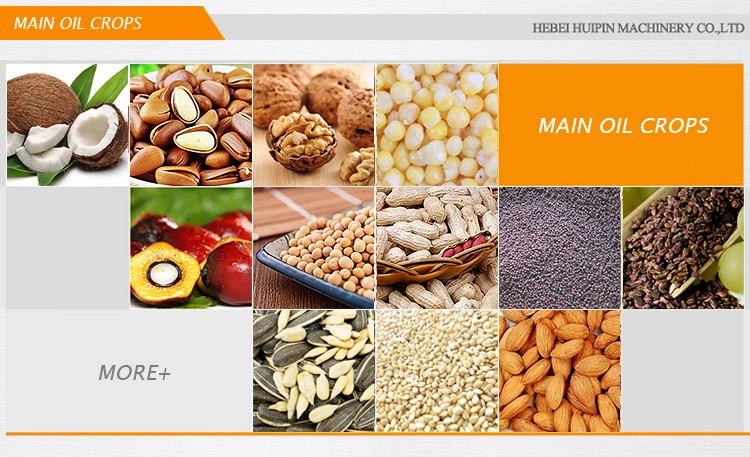

Oil mill machines are complex systems designed to extract oil from various seeds and nuts, such as sunflower, soybean, and palm. These machines operate through a series of mechanical processes, including crushing, pressing, and filtering. The efficiency of these processes largely depends on the equipment's quality and its various components. As with any machinery, the wear and tear over time can impact performance, which is where accessories and servicing come into play.

Essential Accessories for Oil Mill Machines

1. Filters and Purifiers One of the critical accessories for oil mill machines is the filtration system. Filters help ensure that the extracted oil is free from impurities and particulates. High-quality filters not only improve the clarity and quality of the oil but also extend the life of the machine by preventing contaminants from entering the system.

2. Heat Exchangers Temperature control is essential in oil extraction. Heat exchangers help maintain optimal temperatures during the pressing process. This is important because excessive heat can degrade the quality of the oil, while insufficient heat may lead to inefficient extraction. Investing in reliable heat exchangers can markedly improve the overall efficiency of the oil pressing process.

3. Screw Conveyors To enhance the transportation of raw materials and extracted oil, screw conveyors are indispensable. They facilitate the continuous movement of seeds to the mill and ensure that the extracted oil is efficiently directed to storage containers. Properly functioning screw conveyors minimize downtime and help maintain a streamlined production process.

4. Lubrication Systems Having an effective lubrication system is crucial for maintaining the integrity and longevity of oil mill machines. Regular lubrication prevents wear and reduces friction among moving parts, leading to lower maintenance costs and increased operational lifespan.

oil mill machine accessory service

5. Control Panels and Sensors Modern oil mills come equipped with advanced control panels and sensors that monitor various operational parameters. These accessories provide real-time data, enabling operators to make informed decisions and adjustments. Efficient control systems enhance both productivity and safety in oil extraction.

The Role of Service in Oil Mill Operation

While quality accessories are vital, the significance of regular servicing cannot be overstated. Maintenance services ensure that all machine components, including accessories, are functioning optimally. Here are a few key aspects of service

- Routine Inspections Regular inspections allow for the early detection of potential issues before they escalate into more significant problems. Routine checks on filters, lubrication systems, and heat exchangers help maintain optimal performance.

- Preventative Maintenance Scheduled maintenance can prevent unexpected breakdowns. This proactive approach not only saves time but also reduces costs associated with emergency repairs.

- Technical Support Having access to technical support ensures that any issues that arise can be addressed swiftly. Trained technicians can provide insights on the best practices for using accessories and maintaining the machinery effectively.

- Upgrades and Retrofits The technology in oil extraction is continuously evolving. Service providers can offer upgrades or retrofits to existing machines, incorporating the latest technologies to improve efficiency and output.

Conclusion

In summary, the combination of high-quality accessories and comprehensive servicing is essential for the efficient operation of oil mill machines. As the demand for oil continues to grow globally, ensuring that oil extraction processes are optimized will be crucial for staying competitive in the market. By investing in the right accessories and committing to regular maintenance services, businesses can enhance productivity, ensure product quality, and reduce operational costs in the long run.

-

Leading Food Oil Refined Unit Companies | Quality & Efficient Solutions

NewsAug.27,2025

-

Expert Food Oil Refined Unit Companies | Advanced & Efficient Refining

NewsAug.26,2025

-

Food Oil Refined Machine Companies: High-Efficiency Oil Refining

NewsAug.25,2025

-

Popular Commercial Oilseed Crushing Machinery | High-Yield Oil Expeller Press

NewsAug.24,2025

-

Food Oil Refined Unit Companies: Leading Manufacturers & Exporters

NewsAug.23,2025

-

Expert Oil Filter Machine Service & Solutions | Quality & Reliability

NewsAug.22,2025