Mar . 12, 2024 14:09 Back to list

oil press -Solar-Powered Oil Press for Sesame Seed

Solar-Powered Oil Press for Sesame Seed

Introduction

Sesame (Sesamum indicum L.) is the third largest agricultural export crop in Burkina Faso, behind ruminants and cotton (Guissou R., 2012).[1] Sesame oil production is partly established in the country, but not fully developed as energy costs for processing have always been a major challenge. In 2014, Burkina Faso had one of the highest prices for electricity with an average sale price of 126.79 FCFA/kWh (Ouedraogo, Kouame, Azoumah, & Yamegueu, 2015).[2] As a Sahelian country, solar energy, on the other hand, is the most abundant resource with around 8.3 h per day of insolation and 5.5 kWh/m2/day (Azoumah, Ramdé, Tapsoba, & Thiam, 2010).[3] Unfortunately, this energy potential is not fully used by the local industries or cooperatives, which would create a significant benefit for the local economy. In this line, the objective of this project is to evaluate the feasibility of solar-powered sesame oil production, taking into consideration real conditions of medium and small scale enterprises in rural areas of Burkina Faso.

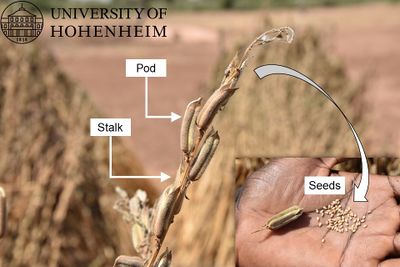

Fig. 1. Sesame stalks, pod and seeds.

Current sesame oil production in Burkina Faso

Mechanical oil extraction done by using a screw press is still considered as a new technology in rural areas in Burkina Faso. The oil press currently in use requires a high power input as shown in Fig. 2. The oil press available in Burkina Faso was imported from China and is commonly provided for industrial scale with up to 100 tons capacity of sesame seeds per year. The oil press is run by an electric motor with power requirements from 7 to 15 kW, and has been used for extracting soybean and sesame oil with an hourly capacity of 80 to 500 kg/h. Therefore, only some big scale oil producers or women's cooperative can afford to purchase and operate this machine.

Fig. 2. Common plant oil production in Burkina Faso at industrial scale.

The use of a solar-powered oil press using photovoltaic panels still requires further research under laboratory conditions and on-field experience. Before implementing the system on the field, the specifications of solar components such as batteries, charge controller and inverter need to be previously defined. Moreover, the performance of the system under different extreme weather conditions at a local scale has to be estimated.

Testing bench for a solar-powered oil press

During the tests, the KK 20 F oil press (Kern Kraft oil press GmbH & Co. KG, Reut, Germany) was used. With a capacity of up to 20 kg/h it is suitable for small- and medium-scale cooperatives. The pressing experiment was conducted at the University of Hohenheim and aimed to characterize the oil press. See Fig. 3.

Fig. 3. Sesame oil production using a small-scale oil press.

In order to determine the extraction performance, components, types and sizes of the appropriate solar equipment (panels, batteries, inverters, charge controllers), as well as the cost-effectiveness of the system, research was conducted as follows. Using weather and sunshine data from a targeted area in Burkina Faso, and press characterization, a simulation of oil extraction was created on computer using the software MATLAB R2017 (The Mathworks Inc, Massachusetts, USA).

By playing on the parameters of the simulation, and by analyzing the results of production, consumed energy, extraction efficiency, the optimum operating conditions were determined.

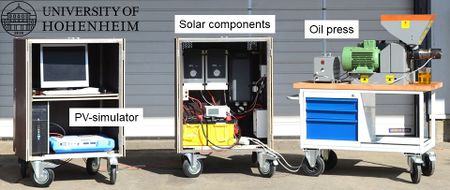

The results obtained from the simulation were validated using a test bench of a solar oil press developed at the University of Hohenheim (see Fig. 4). In order to reproduce the behavior of solar panels in any region of Burkina at any time of the year, the panels have been replaced by a PV simulator.

Fig. 4. Testing bench of a solar-powered oil press for sesame seeds developed at University of Hohenheim, Stuttgart, Germany.

In order to investigate the solar oil pressing performance, three different operation scenarios were developed as follows:

- Scenario 1: The oil press runs at an optimum high screw speed for 24 hours non-stop.

- Scenario 2: The oil press runs at an optimum high screw speed during the day and continues running in the night with low speed.

- Scenario 3: The oil press runs at an optimum high screw speed during the day, but it is stopped during the night.

Oil quality in the interest of EU importation

Figure 5 presents sesame oil produced from the solar-powered oil press and oil from Burkina Faso available on the European market. Quality parameters of the oil such as free fatty acid, peroxide value, vitamin E, oxidation stability and water content were analyzed. It was found that the quality of sesame oil produced from the solar-powered oil press was comparable with the sesame oil sold on the European market and fulfilled the EU standard requirements.

Fig. 5. Sesame oil produced from the solar-powered oil press (left) and oil from Burkina Faso available in a European supermarket.

Collaboration partners

- ProCIV Project, GIZ Burkina Faso

- University of Hohenheim, Agricultural Engineering in the Tropics and Subtropics

- Institut des Sciences Exactes et Appliquées (ISEA), Université Polytechnique de Bobo-Dioulasso

- Centre de Recherche en Sciences Biologiques Alimentaires et Nutritionnelles (CRSBAN), Université Ouaga I, Pr Joseph KI-ZERBO

Performance and profitability of solar-powered sesame oil production

The price of sesame seeds is one of the most important factors determining the profitability of the system and varies depending on the season. During the harvest season, the price for one kg of sesame seeds is 0.91 EUR, while during low season the price can be up to 3.04 EUR. The retail price for one liter of sedimented and filtered sesame oil is 5.33 and 7.62 EUR, respectively. Figure 6 shows the solar-powered sesame oil production on 16 February 2017 with regard to solar energy availability in Bobo-Dioulasso. During the harvest season, the highest solar radiation could be beyond 1000 W/m2, the moisture content of sesame seeds was 8%, and the total running time during the day was 15 h. During this time, 200 kg of sesame seeds were pressed and 78.5 L of sesame crude oil was produced. The maximum power requirement was 900 W.

Fig. 6. Solar-powered sesame oil production using PV-simulator in Burkina Faso.

Running the solar-powered oil press only during the harvest season from October to March was the most profitable operation option (see Fig. 7), due to the low price of sesame seeds. Under optimum condition, the return of investment can be achieved within one year.

Fig. 7. Preliminary economic analysis of solar powered sesame oil production during harvest season.

Future prospects

The use of photovoltaic energy to run the oil press for sesame seeds in Burkina Faso has been seen not only as a sustainable and profitable way to produce electricity but also a cost effective one. It has been found that this unit shows a big potential not only to be highly profitable, but also to create job opportunities in rural areas. Moreover, another important element for providing economic viability and sustainability of the solar-powered unit lies on the oil quality with regard to exportation.

Implementation of solar oil pressing with a small scale capacity at a women's cooperative is suggested. Oil production trials were conducted in the city of Nouna in parallel with the formation of a women's cooperative in the use of oil press and good hygiene and safety practices. The oil produced and analyzed also met European standards (see Fig. 8).

Fig. 8. Production of sesame oil by a cooperative in Nouna

Solar-powered oil production can also be performed for other oilseeds such as groundnuts, cotton seeds and many more.

-

Leading Food Oil Refined Unit Companies | Quality & Efficient Solutions

NewsAug.27,2025

-

Expert Food Oil Refined Unit Companies | Advanced & Efficient Refining

NewsAug.26,2025

-

Food Oil Refined Machine Companies: High-Efficiency Oil Refining

NewsAug.25,2025

-

Popular Commercial Oilseed Crushing Machinery | High-Yield Oil Expeller Press

NewsAug.24,2025

-

Food Oil Refined Unit Companies: Leading Manufacturers & Exporters

NewsAug.23,2025

-

Expert Oil Filter Machine Service & Solutions | Quality & Reliability

NewsAug.22,2025