Dec . 11, 2024 04:24 Back to list

Custom Food Oil Refining Equipment for Efficient OEM Production Solutions

The Importance of OEM Food Oil Refining Machines in Modern Industry

In the contemporary landscape of food production and processing, the demand for high-quality edible oils has significantly increased. Effective refining of these oils is crucial, as it directly impacts their flavor, nutritional value, and shelf life. Original Equipment Manufacturer (OEM) food oil refining machines play a pivotal role in achieving these qualities. This article delves into the need for these machines, their features, and their significance in the food industry.

Understanding Food Oil Refining

Food oil refining is the process of purifying crude vegetable oils to make them suitable for consumption. This process involves several steps, including degumming, neutralizing, bleaching, and deodorizing. Each of these stages is essential to remove impurities, free fatty acids, and undesirable flavors, ensuring that the final product meets regulatory and consumer standards.

OEM food oil refining machines are specialized equipment designed to carry out these processes efficiently. Unlike generic machines, OEM machines are custom-built to meet specific requirements of different oil types, making them more effective in producing high-quality oil.

Features of OEM Food Oil Refining Machines

1. Customization One of the primary advantages of OEM machines is their ability to be customized according to the particular needs of the client. This means the machinery can be tailored for various oil types such as sunflower, canola, palm, and soybean, among others.

2. Superior Technology OEM manufacturers often incorporate advanced technology that enhances the efficiency of oil refining. Features such as automated control systems, precise temperature regulation, and continuous processing capabilities ensure that the oils retain their nutritional and sensory properties.

3. Energy Efficiency In an era where sustainability is paramount, OEM food oil refining machines are often designed to be energy-efficient. This not only helps in reducing operational costs but also aligns with the global objective of minimizing carbon footprints.

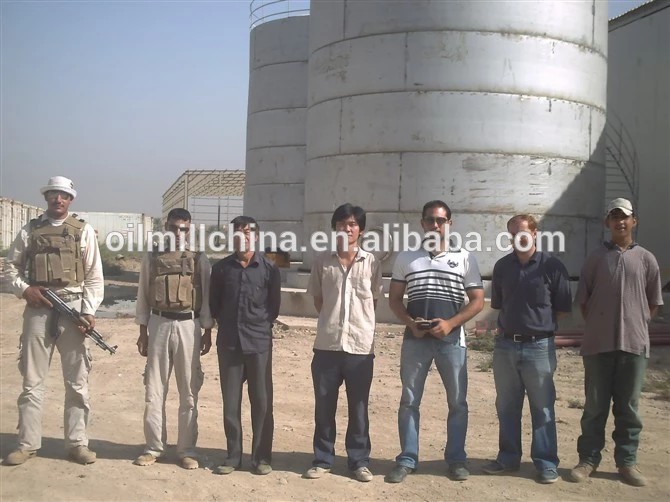

oem food oil refining machine

4. Quality Assurance With stringent quality control measures integrated into the manufacturing process, OEM machines ensure that the end product is consistent in quality. This is crucial for businesses that require a reliable supply of refined oil.

5. Scalability OEM machines can be designed to accommodate various scales of production, whether for small-scale artisanal producers or large industrial operations. This scalability makes them a versatile choice for various business models in the food industry.

Significance in the Food Industry

The importance of OEM food oil refining machines extends beyond just the production of high-quality oils. As consumers become more health-conscious, the demand for refined oils with minimal processing and additive use has surged. These machines facilitate the production of oils that adhere to health standards while also catering to consumer preferences for natural and organic products.

Moreover, the food industry is subjected to rigorous regulations and compliance standards. OEM machines help manufacturers comply with these regulations by ensuring that their processes are efficient and that the final products are free from harmful contaminants.

In addition, as globalization increases, the demand for diverse and specialized oils grows. OEM food oil refining machines enable producers to experiment with various oil types, catering to international markets and consumer tastes.

Conclusion

In summary, OEM food oil refining machines are indispensable in the food oil industry. They provide the necessary tools for refining oils to meet the highest quality standards, ensuring that consumers receive safe, nutritious, and flavorful products. As technology continues to evolve, these machines will play an even more critical role in shaping the future of edible oil production, driving innovation, and meeting the ever-changing demands of the global market. Investing in OEM machinery is not just a business decision; it is a commitment to quality and sustainability in food production.

-

HP 120 Cold Oil Press-Hebei Huipin Machinery|Oil Extraction, Cold Press

NewsAug.07,2025

-

HP 120 Model Cold Oil Press-Hebei Huipin Machinery|Cold Oil Extraction, High Efficiency

NewsAug.07,2025

-

HP 120 Model Cold Oil Press - High-Efficiency Oil Extraction&Automated Processing

NewsAug.07,2025

-

Safflower Oil Press Service | Expert & Efficient Solutions

NewsAug.07,2025

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery | Advanced Oil Extraction Technology

NewsAug.06,2025

-

HP 120 Cold Oil Press-Hebei Huipin Machinery|Cold Pressing, Oil Extraction

NewsAug.06,2025