Jul . 28, 2024 09:14 Back to list

Manufacturer of Flaxseed Oil Refining Equipment for High-Quality Oil Production Solutions

The Role of Flaxseed Oil Refining Lines in the Edible Oil Industry

Flaxseed oil has gained immense popularity in recent years due to its health benefits, including its richness in omega-3 fatty acids and antioxidants. As demand for this nutritious oil rises, the need for efficient and effective refining processes becomes equally critical. This is where flaxseed oil refining line manufacturers play a pivotal role.

Understanding Flaxseed Oil Refining

Flaxseed oil is extracted from the seeds of the flax plant (Linum usitatissimum) through mechanical pressing or solvent extraction. However, raw flaxseed oil can contain impurities, such as free fatty acids, phosphatides, and color pigments, which can affect its shelf life and overall quality. Consequently, refining is necessary to enhance the oil’s properties, making it more suitable for human consumption.

The refining process typically involves several steps degumming, neutralization, bleaching, and deodorization. Each stage is crucial for removing specific impurities and ensuring the final product meets health and safety standards.

1. Degumming This initial step involves the removal of glycerol phosphatides and other hydrophilic impurities. By adding water or acid to the oil, these impurities become hydrated, allowing for easier separation.

2. Neutralization This step involves treating the oil with alkaline substances to neutralize free fatty acids, which can lead to off-flavors and odors.

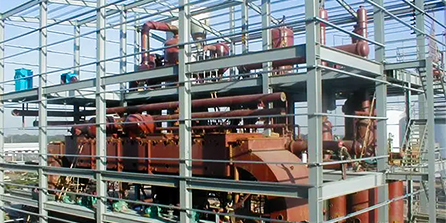

flaxseed oil refining line manufacturer

4. Deodorization The final stage utilizes steam distillation to eliminate volatile odor compounds, ensuring that the oil has a neutral flavor profile.

Importance of Choosing the Right Manufacturer

When it comes to refining flaxseed oil, selecting a reliable manufacturer of refining lines is paramount. A reputable manufacturer will provide cutting-edge technology that ensures maximum efficiency and minimal waste. They should also offer customization based on the specific needs of your production scale and the quality of oil you aim to produce.

Technological Advancements

Recent advancements in refining technologies have led to more sustainable processes. For example, many manufacturers have integrated innovative techniques such as enzymatic degumming and physical refining, which reduce the need for chemicals and enhance the oil’s nutritional properties. Automation and monitoring systems have also improved efficiencies, reducing energy consumption and operational costs.

Moreover, with the growing consumer demand for organic and non-GMO products, manufacturers are adjusting their refining lines accordingly. They offer solutions that adhere to strict organic certifications, helping producers meet market requirements without compromising on quality.

Conclusion

As the global demand for flaxseed oil continues to rise, the role of flaxseed oil refining line manufacturers becomes increasingly vital. They not only provide the necessary equipment to ensure high-quality oil production but also advance the technology that makes the refining process more efficient and sustainable. By focusing on quality assurance and embracing modern techniques, these manufacturers help producers meet consumer demands and contribute to a healthier food supply. Investing in a reliable flaxseed oil refining line is not just an operational decision, but a commitment to quality and sustainability in the edible oil industry.

-

HP 120 Cold Oil Press-Hebei Huipin|Efficient Extraction&Multi-Use

NewsAug.16,2025

-

HP 120 Cold Oil Press-Hebei Huipin|High-Efficiency Oil Extraction&Cold Press Technology

NewsAug.16,2025

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery | High Efficiency Oil Extraction Machine

NewsAug.16,2025

-

Food Oil Refined Machines: Quality & Efficient Oil Refining

NewsAug.16,2025

-

HP 120 Cold Oil Press - Hebei Huipin Machinery|Oil Extraction&Efficiency

NewsAug.15,2025

-

HP 120 Cold Oil Press - Hebei Huipin Machinery | Automated Oil Extraction&High Efficiency

NewsAug.15,2025