Aug . 14, 2024 07:09 Back to list

Leading Innovations in Edible Oil Refinery Plant Manufacturing and Processing Solutions for Sustainable Production

The Edible Oil Refinery Plant A Gateway to Quality and Purity

In the modern food industry, the demand for high-quality edible oils has surged, necessitating the establishment of sophisticated edible oil refinery plants. These facilities play a crucial role in transforming crude vegetable oils into refined products that meet both safety standards and consumer preferences. This article explores the significance of edible oil refinery plants, their operational processes, and the impact they have on food quality and public health.

The Importance of Edible Oil Refining

Crude oils extracted from seeds, nuts, and fruits often contain impurities, including free fatty acids, phospholipids, pigments, and other contaminants. The presence of these impurities can adversely affect the flavor, color, shelf life, and nutritional value of the oil. Edible oil refinery plants are designed to remove these unwanted substances through a series of processing stages, resulting in oils that are not only safe for consumption but also appealing to the senses.

The refining process improves the oil's characteristics and enhances its stability, making it suitable for a wide range of culinary applications. Refined oils have a higher smoke point, which is essential for frying, and they possess a neutral flavor that allows other ingredients to shine in dishes. This versatility makes refined edible oils indispensable in both home kitchens and the foodservice industry.

The Refining Process

The refining of edible oil typically involves several key steps degumming, neutralization, bleaching, and deodorization.

1. Degumming This initial step involves the removal of phospholipids and other water-soluble impurities. By treating the crude oil with water or acid, these impurities are separated, producing a clearer product.

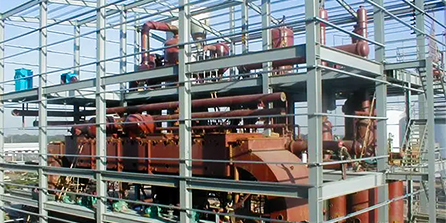

edible oil refinery plant factory

2. Neutralization In this stage, free fatty acids are removed from the oil through an alkali treatment. This process not only lowers the acidity of the oil but also enhances its flavor and shelf life.

3. Bleaching The bleaching process involves removing pigments, such as chlorophyll and carotenoids, using adsorbent materials like activated clay. This step results in a lighter-colored oil that is visually appealing to consumers.

4. Deodorization The final refining step takes place under high temperature and vacuum conditions to remove volatile compounds that can impart undesirable odors or flavors. The result is a neutral, odorless oil suitable for various culinary uses.

Health and Safety Considerations

Consumers are becoming increasingly health-conscious, leading to a greater demand for oils free from harmful substances. Refined edible oils must adhere to strict food safety regulations, ensuring that they are devoid of contaminants and toxins. Modern edible oil refinery plants incorporate advanced technology and stringent quality control measures to maintain high standards of purity.

Moreover, many consumers are now looking for oils that are rich in healthy fats, such as polyunsaturated and monounsaturated fatty acids. Refineries are responding to this demand by producing oils that retain beneficial nutrients while maintaining quality.

Conclusion

The edible oil refinery plant is a vital component of the food supply chain, bridging the gap between raw oil production and consumption. Through the meticulous refining process, these facilities ensure that consumers have access to high-quality edible oils that promote health and delight the palate. As the landscape of food production continues to evolve, the role of edible oil refineries in enhancing food quality and safety will only become more significant, showcasing their importance in today's marketplace.

-

HP 120 Cold Oil Press-Hebei Huipin|Efficient Extraction&Multi-Use

NewsAug.16,2025

-

HP 120 Cold Oil Press-Hebei Huipin|High-Efficiency Oil Extraction&Cold Press Technology

NewsAug.16,2025

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery | High Efficiency Oil Extraction Machine

NewsAug.16,2025

-

Food Oil Refined Machines: Quality & Efficient Oil Refining

NewsAug.16,2025

-

HP 120 Cold Oil Press - Hebei Huipin Machinery|Oil Extraction&Efficiency

NewsAug.15,2025

-

HP 120 Cold Oil Press - Hebei Huipin Machinery | Automated Oil Extraction&High Efficiency

NewsAug.15,2025