Jul . 29, 2024 22:56 Back to list

High Efficiency Horizontal Oil Filter Solutions for China’s Industrial Applications and Oil Refining Needs

The Importance of Horizontal Oil Filters in Modern Machinery

In the world of industrial machinery and automotive applications, efficient oil filtration is essential for ensuring the longevity and performance of engines and mechanical systems. One of the increasingly popular technologies in this realm is the horizontal oil filter, notably prevalent in various types of machinery, including generators, compressors, and automotive vehicles. China has seen significant advancements in the manufacturing and adoption of horizontal oil filters, reflecting both technological innovation and a growing emphasis on sustainability and efficiency.

Understanding Horizontal Oil Filters

Horizontal oil filters are designed to provide a robust solution for the filtration needs of machinery that requires continuous and efficient oil circulation. Unlike traditional vertical filters, horizontal filters are laid out flat, which allows for better sedimentation and filtration of contaminants. This design promotes faster flow rates and minimizes the risk of clogging, ensuring a more reliable oil supply to critical components.

The construction of horizontal oil filters typically includes a cylindrical casing housing the filter media, which can be made from various materials such as synthetic fibers, cellulose, or metal mesh. The choice of filter media is crucial as it determines the size of particles that can be captured. In many industrial applications, the need to filter out microscopic particles to prevent wear and tear on engine components is paramount.

Advantages of Horizontal Oil Filters

One major advantage of horizontal oil filters is their efficiency in handling larger volumes of oil. This capacity makes them suitable for heavy-duty applications and machinery that operate under high-stress conditions. Moreover, horizontal filters generally require less maintenance compared to their vertical counterparts, as they can be cleaned and serviced more easily without the need for extensive disassembly.

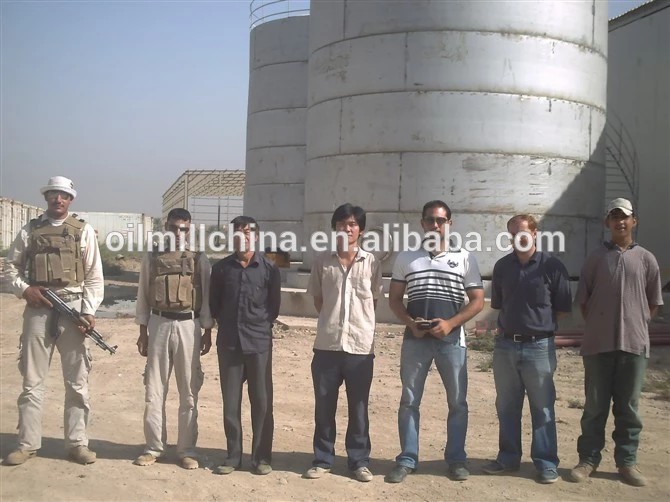

china horizontal oil filter

Another significant benefit is the orientation that leads to better fluid dynamics. In horizontal filters, oil flows parallel to the filter material, allowing for a more extended contact time between the oil and the filter media. This increased contact time equates to superior particulate removal, ultimately contributing to cleaner oil circulation and better engine performance.

Market Dynamics in China

As a major player in the global machinery and automotive markets, China has recognized the importance of high-quality oil filtration systems. The demand for efficient horizontal oil filters has surged as industries strive for greater efficiency and regulatory compliance regarding emissions and waste management. Chinese manufacturers have responded by innovating and producing advanced filtration systems that not only meet national quality standards but also cater to international markets.

The growth of the automotive sector in China has also driven the need for horizontal oil filters, as manufacturers seek to enhance engine performance and longevity while minimizing environmental impact. With a focus on sustainability, many companies are adopting recyclable or biodegradable materials for their filters, aligning with global environmental trends.

Conclusion

The role of horizontal oil filters in enhancing the performance and sustainability of machinery cannot be overstated. As China continues to innovate and improve its manufacturing capabilities, horizontal oil filters are set to play a pivotal role in shaping the future of industrial and automotive lubrication systems. By embracing advanced filtration technologies, industries can ensure cleaner, more efficient operations while contributing to the global push for sustainability. As the demand for high-quality oil filtration grows, the development and optimization of horizontal oil filters will remain a key focus area for manufacturers both in China and around the world.

-

High-Efficiency Peanut Oil Refined Machine for Quality Oil Production Leading Exporters & Companies

NewsJul.08,2025

-

High Efficiency Sunflower Seed Oil Press – Leading Cooking Oil Press Machine Factories & Suppliers

NewsJul.08,2025

-

High-Efficiency Soybean Oil Press Machine – Leading Exporters & Reliable Companies

NewsJul.07,2025

-

High-Efficiency Seed to Oil Extractor – Reliable Extraction Machinery for Your Business

NewsJul.07,2025

-

High-Quality Pressing Screw of Oil Expeller for Efficient Oil Extraction Leading Exporters & Manufacturers

NewsJul.06,2025

-

High-Efficiency Essential Oil Extraction Machine Trusted Exporters & Companies

NewsJul.06,2025