Aug . 18, 2024 14:03 Back to list

Extraction Centrifuge Manufacturing Facility Overview and Key Features

The Role of Extraction Centrifuge Factories in Modern Industry

Centrifuges have become indispensable tools in a wide range of industrial applications, particularly in the extraction processes within various manufacturing settings. Extraction centrifuge factories, which specialize in the production of these vital machines, play a crucial role in enhancing efficiency, productivity, and quality in various sectors, including pharmaceuticals, food processing, and wastewater treatment.

At the core of many industrial processes, extraction centrifuges operate on the principle of centrifugal force, separating components of different densities within a mixture. This technology allows for the efficient extraction of valuable substances, such as oils, proteins, and other biochemical compounds. As industries continue to evolve and demand higher purity levels and better yield, the importance of advanced extraction centrifuges becomes even more pronounced.

The Role of Extraction Centrifuge Factories in Modern Industry

One of the primary sectors benefiting from extraction centrifuge technology is the pharmaceutical industry. In drug production, the purity of active pharmaceutical ingredients (APIs) is paramount. Extraction centrifuges ensure that impurities are effectively separated, leading to higher quality medicines. Additionally, the increasing demand for biopharmaceuticals has driven the need for more sophisticated extraction techniques, which in turn has spurred growth in extraction centrifuge factories that specialize in biologically-derived substances.

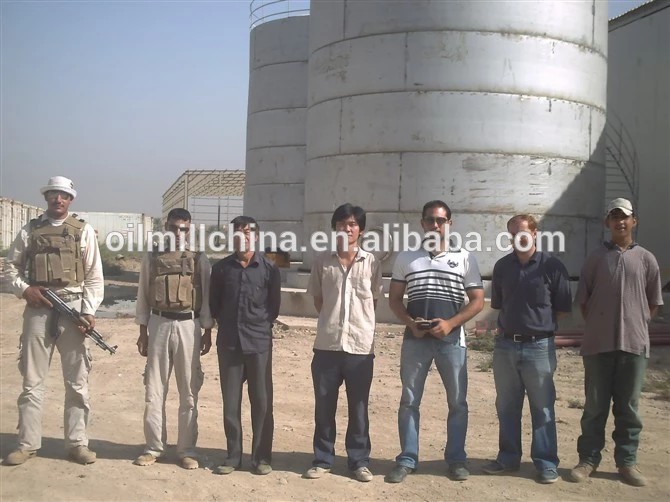

extraction centrifuge factory

Similarly, the food industry has seen significant improvements in the extraction processes for essential oils, flavors, and nutrients. Extraction centrifuges facilitate the efficient extraction of these components, ensuring that food products are not only safe and compliant with regulations but also rich in flavor and nutritional value. For instance, olive oil extraction has benefited immensely from the implementation of modern centrifuge technology, allowing producers to obtain high-quality oil with minimal loss of flavor and health benefits.

Environmental considerations are also driving advancements in extraction centrifuge technology. As industries face increasing scrutiny regarding their environmental impact, extraction processes that are efficient and sustainable are becoming critical. Modern extraction centrifuges are designed to minimize waste and energy consumption, which is vital in industries where sustainability is a growing requirement. By using these advanced machines, companies can demonstrate their commitment to environmentally responsible practices while also cutting down on operational costs.

Moreover, the adaptability of extraction centrifuges allows them to be employed across various applications, making them a versatile choice for manufacturers. Whether it’s in the extraction of biofuels, the processing of dairy products, or the recovery of valuable metals from waste, extraction centrifuges provide a reliable and efficient solution tailored to the specific needs of the industry.

In conclusion, extraction centrifuge factories are essential players in the modernization and efficiency of industrial processes. By producing state-of-the-art equipment that meets the evolving demands of various sectors, these factories not only contribute to higher productivity but also support sustainability efforts. As industries continue to seek innovative ways to enhance their operations, the significance of extraction centrifuges and the factories that produce them will only continue to grow, shaping the future of extraction technology and its applications across the globe.

-

Food Oil Refined Machine Companies: High-Efficiency Oil Refining

NewsAug.25,2025

-

Popular Commercial Oilseed Crushing Machinery | High-Yield Oil Expeller Press

NewsAug.24,2025

-

Food Oil Refined Unit Companies: Leading Manufacturers & Exporters

NewsAug.23,2025

-

Expert Oil Filter Machine Service & Solutions | Quality & Reliability

NewsAug.22,2025

-

LZY-206 Double Screw Cold Oil Press – Maximize Yield, Preserve Nutrients

NewsAug.21,2025

-

Efficient Black Seed Oil Expeller & Multi-Seed Oil Press

NewsAug.19,2025