Jul . 27, 2024 05:50 Back to list

Exploring Leading Oil Expeller Companies and Their Innovative Press Screw Technologies for Enhanced Efficiency

The Role of Press Screws in Oil Expeller Companies

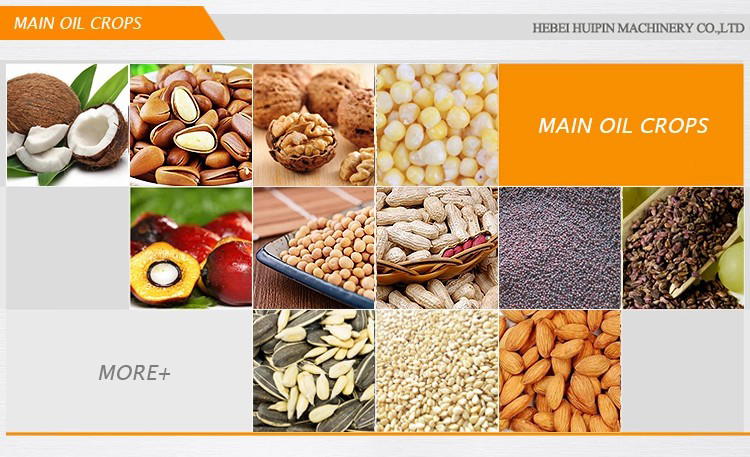

In the realm of oil extraction, one of the most vital components is the press screw. Oil expeller companies, which specialize in the production of vegetable oils, rely heavily on this technology to efficiently separate oil from oilseeds. The press screw serves as a crucial element that determines the efficiency, yield, and quality of the extracted oil. Understanding its workings and significance is essential for anyone involved in the oil extraction industry.

The Role of Press Screws in Oil Expeller Companies

One of the primary advantages of using press screws in oil expellers is their efficiency. Modern press screws are designed with advanced technologies that allow for higher extraction rates compared to traditional methods. Many oil expeller companies invest in research and development to enhance the design of press screws. Features such as adjustable pressure settings and optimized screw profiles can significantly boost the yield of oil, ensuring that the oilseeds are fully utilized. For businesses operating in competitive markets, these enhancements can be the difference between profitability and loss.

press screw of oil expeller companies

Moreover, the choice of materials used in the construction of press screws is pivotal. High-quality steel or alloy materials are often employed to ensure durability and withstand the high pressures involved in the oil extraction process. Innovative coatings and treatments can also be applied to reduce friction and wear, extending the lifespan of the equipment. As a result, oil expeller companies benefit not only from improved efficiency but also from reduced maintenance costs.

The role of the press screw extends beyond merely extracting oil; it also influences the quality of the end product. The temperature during the pressing process can affect the flavor, color, and nutritional properties of the oil. Companies that utilize advanced press screw technology can better control the extraction temperature, resulting in superior quality oils. This is particularly important in the market for gourmet oils, where consumers demand high standards in flavor and quality.

In addition to enhancing extraction efficiency and oil quality, the press screw system contributes to sustainability in oil production. With a global movement towards sustainable practices, oil expeller companies are under pressure to minimize waste and energy consumption. Press screws typically generate less heat during operation, leading to a reduction in energy use. Furthermore, the solid byproduct of the extraction process, usually in the form of meal or cake, can be repurposed as animal feed or organic fertilizer, minimizing waste and maximizing resource utilization.

In conclusion, the press screw is an indispensable element of oil expeller companies. Its ability to efficiently extract oil while maintaining quality has made it a cornerstone of modern oil extraction technology. As oil expeller companies continue to innovate and improve their processes, the role of the press screw will undoubtedly evolve, becoming even more integral to sustainable and efficient oil production. Investing in advanced press screw technology is not just a matter of competitive advantage; it is a commitment to quality, sustainability, and the future of the oil extraction industry.

-

HP 120 Cold Oil Press - Hebei Huipin Machinery|Oil Extraction&Efficiency

NewsAug.15,2025

-

HP 120 Cold Oil Press - Hebei Huipin Machinery | Automated Oil Extraction&High Efficiency

NewsAug.15,2025

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery | High-Efficiency Oil Extraction & Automated Processing

NewsAug.15,2025

-

HP 120 Cold Oil Press-Hebei Huipin Machinery|Oil Extraction, Cold Press Technology

NewsAug.15,2025

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery Co., Ltd. | High Automation, Multi-Functional Compatibility

NewsAug.15,2025

-

Efficient Black Seed Oil Expeller | High Yield Oil Press Machine

NewsAug.15,2025