Nov . 20, 2024 15:15 Back to list

disk sheller product

The Innovative World of Disk Shellers Revolutionizing Shelling Processes

In the agricultural and food processing industries, efficiency and precision play critical roles in ensuring that products meet consumer demands and quality standards. Among various technological advancements, the introduction of disk shellers has emerged as a game-changer. Disk shellers are specialized machines designed for separating the edible parts of grains, nuts, and seeds from their shells, drastically improving productivity and reducing labor costs.

What is a Disk Sheller?

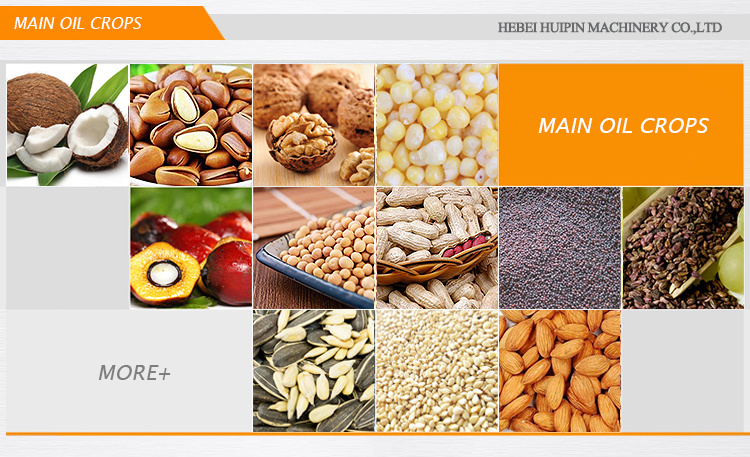

A disk sheller is a mechanical device that utilizes a series of rotating disks to facilitate the shelling process. These disks are engineered with precision, allowing them to apply optimal pressure on the material being processed, ensuring that the shells are effectively removed without damaging the valuable edible portions inside. Disk shellers can handle different types of produce, including corn, almonds, and various other nuts and seeds, making them versatile tools in agricultural operations.

Operational Efficiency

One of the primary advantages of using disk shellers is their operational efficiency. Traditional shelling methods, which often rely on manual labor, are not only time-consuming but can also result in inconsistent shelling quality. Disk shellers automate the process, allowing for faster throughput and more consistent results. Moreover, the energy consumption of these machines is generally lower than that of traditional systems, leading to both cost savings and a reduced environmental footprint.

Precision and Quality

Disk shellers are engineered to enhance the quality of the final product. The design of the disks allows for precise adjustments to be made according to the specific type of material being processed. This adaptability ensures that the shelling is carried out without damaging the kernels or seeds. As a result, the percentage of intact, high-quality produce that can be recovered is significantly higher compared to manual shelling or less sophisticated machines.

disk sheller product

Versatility in Applications

The applications of disk shellers extend beyond just the agricultural sector. In the food processing industry, for example, businesses that deal with processed nuts and grains can greatly benefit from these machines. Manufacturers can use disk shellers to streamline their production processes, resulting in faster turnaround times and increased output. Additionally, the adaptability of disk shellers means they can be configured for various sizes and types of produce, making them an essential tool for diverse operations.

Maintenance and Longevity

Another compelling reason to invest in disk shellers is their durability and ease of maintenance. Built with high-quality materials, these machines are designed to withstand the rigors of continuous use. Regular maintenance protocols can easily be integrated into standard operating procedures, ensuring that the machines operate smoothly and efficiently for years. This reliability makes disk shellers a wise investment for businesses looking to improve their production capabilities.

Conclusion

The advent of disk shellers represents a significant advancement in the shelling process, offering unprecedented efficiency, quality, and versatility. As the food industry continues to evolve, embracing technology is essential to meet the demands of a growing population while maintaining high standards of quality. Disk shellers not only cater to these needs but also reflect a commitment to sustainable agricultural practices by reducing waste and optimizing resource use.

For farmers and manufacturers looking to modernize their operations, investing in disk shellers should certainly be on the agenda. By leveraging this innovative technology, businesses can position themselves competitively in the marketplace while delivering superior quality products to consumers. Ultimately, disk shellers are more than just machines; they are pivotal in shaping a sustainable and efficient future for the food industry.

-

HP290 First Press Oil Expeller Machinery: Efficient Oil Extraction

NewsAug.02,2025

-

Top Food Oil Refined Unit Companies w/ GPT-4 Turbo Tech

NewsAug.01,2025

-

Premium Black Seed Oil Expeller - High Efficiency Cold Press Oil Machine

NewsJul.31,2025

-

Oil Processing Equipment - High-Efficiency Flaking Machine

NewsJul.25,2025

-

High-Efficiency Peanut Oil Refined Machine for Quality Oil Production Leading Exporters & Companies

NewsJul.08,2025

-

High Efficiency Sunflower Seed Oil Press – Leading Cooking Oil Press Machine Factories & Suppliers

NewsJul.08,2025