Dec . 14, 2024 05:51 Back to list

Cottonseed Shelling Equipment and Factory Solutions for Efficient Processing

The Role of Cottonseed Sheller Factories in the Cotton Industry

Cotton is one of the most significant cash crops globally, playing a crucial role in the textile industry and agriculture economies. Part of the cotton processing involves separating the cotton fibers from the seeds, a procedure typically carried out in cottonseed sheller factories. These factories not only enhance the efficiency of cotton processing but also contribute to the overall value chain of cotton production.

The Function of Cottonseed Sheller Factories

Cottonseed sheller factories are specialized facilities designed to extract cotton fibers from the seeds. The process begins with the introduction of raw cotton bales into the factory, where advanced machinery is employed to remove the seeds from cotton fibers. Traditionally, this process was labor-intensive, requiring substantial manual effort. However, modern technology has revolutionized this operation, making it highly mechanized and efficient.

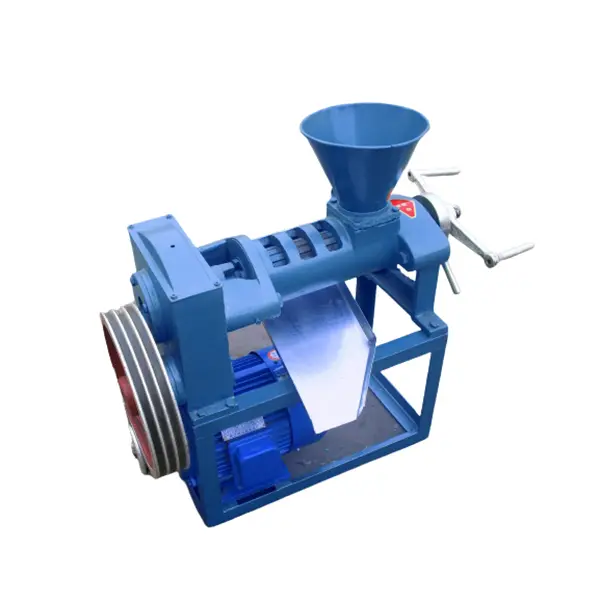

The primary equipment used in these factories includes cottonseed hoppers, seed separators, and lint cleaners. The hoppers feed the raw cotton into the machine, where it is treated to break down the fibers and seeds. The separation process ensures that the cotton fibers, suitable for textile production, are collected, while the seeds are either discarded or processed further.

Importance of Cottonseed Processing

The processing of cottonseed is vital for several reasons. First and foremost, it helps in optimizing the value derived from cotton cultivation. The fibers can be transformed into a variety of textile products, from clothing to home furnishings. In contrast, the seeds are not merely waste; they can be processed into cottonseed oil, a valuable cooking oil, and animal feed. Thus, cottonseed sheller factories enable the utilization of the entire cotton plant, reducing waste and enhancing sustainability in cotton production.

Economic Impact

cottonseed sheller factories

Cottonseed sheller factories contribute significantly to local and national economies. They create jobs, both directly and indirectly, supporting a range of positions from factory workers to logistics and distribution managers. Additionally, these factories often source their raw materials from local farmers, thereby boosting agricultural economies and ensuring that farmers receive a fair price for their crops.

Moreover, as the demand for cotton and cotton products grows globally, the efficiency and productivity of cottonseed sheller factories become more critical. The continuous innovation in processing techniques not only improves output but also decreases processing times and reduces costs, benefiting both producers and consumers.

Environmental Considerations

As industries strive for sustainability, cottonseed sheller factories can play a critical role in adopting eco-friendly practices. Modern factories are increasingly investing in clean energy sources and efficient waste management systems. For instance, by using eco-friendly methods to transform cottonseed waste into biofuels or organic fertilizers, these factories can minimize their environmental footprint.

Additionally, advancements in technology allow for the recycling of water used in processing, further conserving vital resources. By focusing on sustainable practices, cottonseed sheller factories help address environmental concerns while maintaining productivity.

Conclusion

In summary, cottonseed sheller factories are indispensable in the cotton industry, enhancing the efficiency of cotton processing and promoting the sustainable use of cotton plants. These facilities not only contribute to the economic wellness of communities but also support advancements in sustainable agricultural practices. As the cotton industry continues to evolve, the role of cottonseed sheller factories will remain critical in meeting the demands of a growing global market while embracing environmental stewardship. The future of cotton production depends not only on the efficiency of these factories but also on their ability to innovate and adapt to changing trends in sustainability.

-

LZY-206 Twin-Screw Cold Press: Efficient Oil Extraction

NewsAug.04,2025

-

Professional Safflower Oil Press Service | AI-Efficient

NewsAug.03,2025

-

HP290 First Press Oil Expeller Machinery: Efficient Oil Extraction

NewsAug.02,2025

-

Top Food Oil Refined Unit Companies w/ GPT-4 Turbo Tech

NewsAug.01,2025

-

Premium Black Seed Oil Expeller - High Efficiency Cold Press Oil Machine

NewsJul.31,2025

-

Oil Processing Equipment - High-Efficiency Flaking Machine

NewsJul.25,2025