Nov . 08, 2024 16:12 Back to list

cheap camellia seed oil production line

The Production Line of Cheap Camellia Seed Oil A Comprehensive Overview

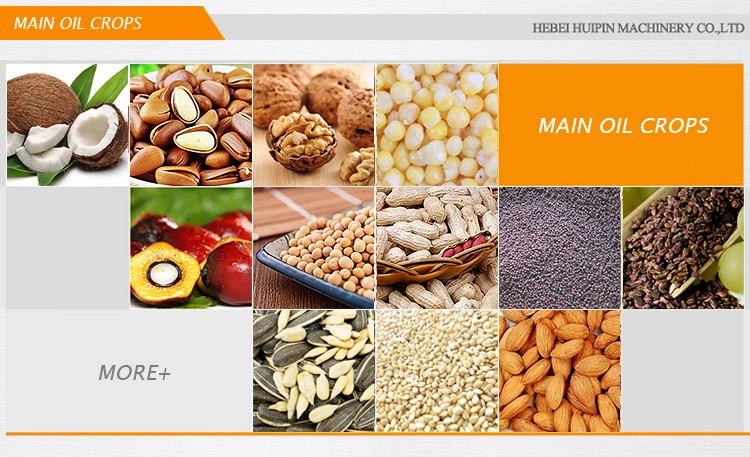

Camellia seed oil, derived from the seeds of the Camellia oleifera plant, has gained popularity in recent years due to its numerous health benefits and applications in the culinary and cosmetic industries. As demand for this oil increases, establishing an efficient production line becomes essential to ensure sustainable and cost-effective manufacturing. This article explores the components, processes, and insights related to a cheap camellia seed oil production line.

1. Raw Material Sourcing

The foundation of any successful production line begins with sourcing quality raw materials. For camellia seed oil, the seeds are primarily harvested from the Camellia oleifera tree, native to southern China and other East Asian regions. The seeds must be collected at the right time to ensure optimal oil yield and quality. An ideal production line will establish relationships with local farmers and cooperatives to secure a steady supply of high-quality seeds at a reasonable cost.

2. Seed Cleaning and Preparation

Upon arrival at the production facility, the camellia seeds undergo a rigorous cleaning process to remove impurities such as dirt, leaves, and damaged seeds. This step is crucial as any contaminants can affect the quality and safety of the final product. After cleaning, the seeds may be hulled to enhance oil extraction by maximizing the surface area. Effective cleaning and preparation techniques can significantly influence the cost-effectiveness of the production line.

3. Oil Extraction Methods

The extraction of oil from camellia seeds can be achieved through various methods, with the two most common being cold pressing and solvent extraction.

- Cold Pressing is a traditional method that involves mechanically pressing the seeds to extract oil without applying heat

. This method is viewed as the most natural form of extraction, preserving the oil’s nutritional properties. However, it may yield lower quantities than other methods.cheap camellia seed oil production line

- Solvent Extraction uses chemical solvents to dissolve the oil from the seeds. While this method can maximize oil yield, it does necessitate additional purification steps to remove any residual solvents from the final product.

Choosing an appropriate extraction method is paramount for balancing cost and quality, particularly in a production line aimed at affordability without compromising on the quality of camellia seed oil.

4. Filtration and Refining

After extraction, the crude camellia seed oil will undergo filtration to remove any remaining solids and impurities. This process can involve coarse filtering followed by fine filtering to achieve a clear product. Additionally, refining may be required, which can include degumming, neutralization, bleaching, and deodorization processes. These refining steps help enhance the oil's taste, aroma, and shelf life, making it more appealing for consumers in culinary and cosmetic applications.

5. Packaging and Distribution

Once the camellia seed oil is refined and filtered, it is ready for packaging. The choice of packaging materials is critical, as they should protect the oil from light, air, and moisture, which can lead to rancidity. Affordable and eco-friendly packaging solutions, such as glass bottles or recycled plastic containers, can be implemented to cater to environmentally conscious consumers.

The final step is distribution, where partnerships with local and international distributors can help bring the product to market efficiently. An effective logistics strategy ensures that the camellia seed oil reaches consumers while maintaining its quality.

Conclusion

The production line of cheap camellia seed oil encompasses multiple stages, from raw material sourcing to final distribution. By focusing on each step, manufacturers can create a cost-effective production process that delivers high-quality oil to the market. As the demand for camellia seed oil continues to rise, optimizing production lines and fostering sustainability will be crucial in meeting consumer expectations and promoting the oil’s health and cosmetic benefits. With the right strategies, camellia seed oil can be positioned not only as a valuable product but also as a sustainable and economical choice for consumers worldwide.

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery | Advanced Oil Extraction Technology

NewsAug.06,2025

-

HP 120 Cold Oil Press-Hebei Huipin Machinery|Cold Pressing, Oil Extraction

NewsAug.06,2025

-

HP 120 Cold Oil Press - Hebei Huipin Machinery | Oil Extraction, Automation

NewsAug.06,2025

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery Co., LTD | Labor-Saving, Multi-Functional

NewsAug.06,2025

-

HP 120 Cold Oil Press - Hebei Huipin | Oil Extraction, High Efficiency

NewsAug.06,2025

-

HP 120 Cold Oil Press - Hebei Huipin | High Efficiency & Versatility

NewsAug.06,2025