Oct . 14, 2025 09:05 Back to list

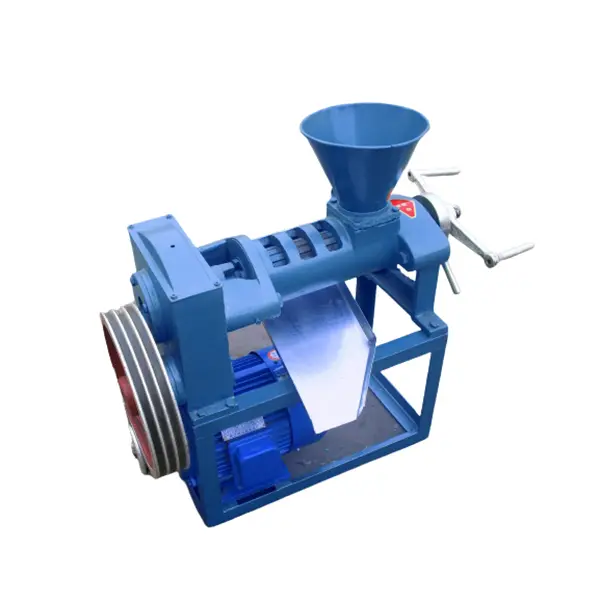

Black Seed Oil Expeller | High Yield, Durable, Low Noise

Field Notes on a black seed oil expeller: HP120 Small Capacity Cold Oil Press

If you’ve been anywhere near a boutique oil line or herbal lab lately, you’ve heard the buzz: cold-pressed Nigella sativa (black seed) is having its moment. The HP120 from Dingzhou City, Hebei Province, China, sits right in that sweet spot—serious engineering without a skyscraper price tag. To be honest, I’ve seen it on shop floors from small nutraceutical brands to farm co-ops; it’s a practical machine rather than a showroom diva.

Why this matters now

Trends are clear: lower-temperature pressing, traceability, and cleaner flavor profiles. Actually, buyers are pushing for documented peroxide values and metal-contact materials. The HP120 leans into that: food-grade contact surfaces, controllable barrel heating (kept minimal for “cold”), and a compact footprint. Many customers say it’s less finicky with small seeds than older multi-stage presses.

Real-world specs (quick glance)

| Model | HP120 Small Capacity Cold Oil Press |

| Seed types | Black seed (Nigella), sesame, flax/linseed, perilla, chia (trial) |

| Capacity | ≈120–250 kg/h (real-world use may vary with seed grade and moisture) |

| Motor power | ≈11–15 kW |

| Screw speed | ≈36–60 rpm adjustable |

| Pressing temperature (cold) | Typically 38–50°C; aim ≤49°C for “cold-press” claims |

| Contact materials | 304/316L stainless in food-contact zones; wear alloy steel screw/barrel |

| Noise | ≈72–78 dB |

| Service life | Screw/barrel ≈8,000–12,000 h before refurbishment (typical) |

Process flow, briefly

- Incoming seeds: sieve cleaning, destoning, magnet trap (per ISO 22000/HACCP).

- Conditioning: gentle warm-air tempering to target moisture ≈6–8%.

- Cold pressing: HP120 single-screw; minimal barrel heat, target ≤49°C.

- Clarification: sedimentation + plate filter (5–10 μm) or polishing filter.

- Nitrogen blanketing (optional) and food-grade packaging.

Testing standards we see on the shop floor: AOCS methods for oil content and residual oil in cake; peroxide value and FFA checks; occasional GC for volatile profile when brands get picky. Service teams often log press temp, throughput, motor load, and TPC in the bottling area.

Applications and feedback

Use cases: small nutraceutical lines, herbal labs, spice mills, farm co-ops, and cosmetics producers seeking fragrant black seed oil. Many operators report cleaner aroma at lower temps and say the cake flows well for feed. Typical test data: oil yield ≈28–35% (seed-dependent), residual oil in cake ≈8–12%, peroxide value fresh ≤5 meq O2/kg when handled with nitrogen and quick filtration.

Comparing vendors (quick buyer’s table)

| Vendor | Origin | Capacity | Warranty | Certifications | Lead time |

|---|---|---|---|---|---|

| HP120 OEM (Hebei) | China | ≈120–250 kg/h | 12–18 months | CE, ISO 9001 (typ.) | ≈20–35 days |

| Henan-based supplier | China | ≈80–200 kg/h | 12 months | CE (varies) | ≈25–45 days |

| EU-import option | EU | ≈60–150 kg/h | 24 months | CE, food-contact docs | ≈6–10 weeks |

Customization and compliance

Options I’ve seen: screw profiles tuned for small seeds, 316L upgrade in contact zones, inverter-driven speed control, jacketed barrel with tighter temp bands, and inline nitrogen. For compliance, buyers typically request CE marking, ISO 9001 QMS, and food-contact declarations. For a black seed oil expeller running consumer products, HACCP documentation and traceable batch logs are smart moves.

Case snapshots

- Herbal brand (MENA): two HP120 lines, yield ≈32% on premium Nigella; upgraded filtration cut turbidity by ~40%.

- Cosmetics lab (EU): low-temp regime (

- Farm co-op (India): multi-seed operation (sesame/black seed); noted low downtime and easy screw changeover.

If you’re speccing a black seed oil expeller for a tight room, the HP120’s footprint and single-screw simplicity keep maintenance sane. And yes, I guess the price-to-performance ratio is the real hook here.

Standards and references

- ISO 22000:2018 – Food safety management systems.

- AOCS Official Methods for oil quality (e.g., peroxide value, residual oil in cake).

- ISO 12100:2010 – Safety of machinery.

- Codex Alimentarius – Fats and Oils Standards (general guidance).

- CE Machinery Directive 2006/42/EC – Conformity requirements.

- HACCP Principles – Codex CAC/RCP 1-1969 (Rev.).

For sourcing: origin is Dingzhou City, Hebei Province, China. Always verify final specs and certifications with the manufacturer before commissioning a black seed oil expeller.

-

Mustard Oil Extraction Machine: A Complete Guide to Industry, Technology & Future Trends

NewsNov.20,2025

-

Groundnut Oil Extraction Machine | Efficient Peanut Oil Press Solutions

NewsNov.20,2025

-

Manual Oil Press Machine: Sustainable Oil Extraction for Global Communities | Buy & Learn More

NewsNov.19,2025

-

Efficient Peanut Oil Machine Solutions for Sustainable Oil Extraction

NewsNov.19,2025

-

Essential Oil Extraction Machine: Unlocking Quality & Sustainability in Oil Production

NewsNov.18,2025

-

Latest Oil Expeller – Efficient & Sustainable Oil Extraction Machines

NewsNov.18,2025