Oct . 01, 2025 01:20 Back to list

Black Seed Oil Expeller with High Yield, Cold Press?

[black seed oil expeller,flaxseed oil refinery unit,flaxseed oil refining line,flaxseed oil mill machine,flaxseed oil expeller,flaxseed oil press,linseed oil mill machine,linseed oil expeller,linseed oil press ,palm kernel pressing machine] is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of grain and oil processing machinery. This article explores how Hebei Huipin Machinery Co.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- [black seed oil expeller,flaxseed oil refinery unit,flaxseed oil refining line,flaxseed oil mill machine,flaxseed oil expeller,flaxseed oil press,linseed oil mill machine,linseed oil expeller,linseed oil press ,palm kernel pressing machine] Overview

- Benefits & Use Cases of [black seed oil expeller,flaxseed oil refinery unit,flaxseed oil refining line,flaxseed oil mill machine,flaxseed oil expeller,flaxseed oil press,linseed oil mill machine,linseed oil expeller,linseed oil press ,palm kernel pressing machine] in Manufacturing of grain and oil processing machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on [black seed oil expeller,flaxseed oil refinery unit,flaxseed oil refining line,flaxseed oil mill machine,flaxseed oil expeller,flaxseed oil press,linseed oil mill machine,linseed oil expeller,linseed oil press ,palm kernel pressing machine] from Hebei Huipin Machinery Co.,LTD

[black seed oil expeller,flaxseed oil refinery unit,flaxseed oil refining line,flaxseed oil mill machine,flaxseed oil expeller,flaxseed oil press,linseed oil mill machine,linseed oil expeller,linseed oil press ,palm kernel pressing machine] Overview

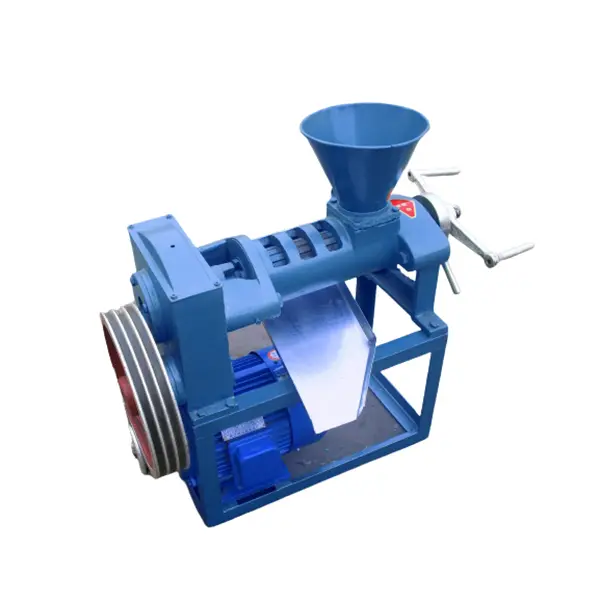

In the Manufacturing of grain and oil processing machinery, precision-built presses and refining systems determine yield, quality, and profitability. Hebei Huipin Machinery Co.,LTD’s HP120 small-capacity cold oil press provides a robust core for a black seed oil expeller, flaxseed oil press or linseed oil press setup, and can be paired with downstream equipment to form a complete flaxseed oil refining line or flaxseed oil refinery unit. For seeds like nigella (black seed) and flax/linseed, temperature control, gentle mechanical action, and optimized screw geometry are critical to preserve delicate omega-rich profiles while maintaining throughput.

Technically, the HP120 platform features a hardened pressing chamber, high-torque gearbox, precise heating/cooling options for cold or warm pressing, and modular screw/pressing rings suited to different raw materials—from soft flaxseed to tougher palm kernel. Typical configurations support continuous operation, sanitary contact surfaces, and easy integration with cleaning, dehulling, flaking, and filtration systems. Whether you operate a flaxseed oil mill machine or a linseed oil mill machine, Huipin’s engineering ensures consistent cake discharge, low residual oil, and stable operation suitable for B2B production lines.

Benefits & Use Cases of [black seed oil expeller,flaxseed oil refinery unit,flaxseed oil refining line,flaxseed oil mill machine,flaxseed oil expeller,flaxseed oil press,linseed oil mill machine,linseed oil expeller,linseed oil press ,palm kernel pressing machine] in Manufacturing of grain and oil processing machinery

For processors building complete value chains, Hebei Huipin Machinery Co.,LTD supplies the press core plus ancillary modules required to scale from pilot to industrial production. A flaxseed oil expeller or linseed oil expeller based on the HP120 enables stable cold pressing to maintain low peroxide values and favorable sensory attributes. When expanded into a flaxseed oil refining line or refinery unit, businesses can add degumming, neutralization, bleaching, and deodorization to meet specific market standards for edible or cosmetic-grade oils.

Applications include black seed oil production for nutraceuticals, linseed oil for food and coatings, and palm kernel pressing machine deployments for lauric oils. Competitive advantages include: adaptable screw sets for multi-seed operations; fast changeover to reduce downtime; robust wear parts for long service intervals; and automation-ready controls to stabilize yield. Huipin’s domain expertise in Manufacturing of grain and oil processing machinery ensures process integration—from seed preparation to final filtration—so operators can hit target capacities and quality specs with fewer adjustments.

Cost, Maintenance & User Experience

Total cost of ownership is driven by energy consumption, spare parts life, uptime, and labor. The HP120-based flaxseed oil mill machine or linseed oil mill machine is engineered for efficient kWh-per-ton metrics and straightforward maintenance: accessible bearings, standardized wear components, and clean-in-place-friendly surfaces. For operations considering a black seed oil expeller, the minimized residual oil in cake and lower thermal load can translate into higher net yields and better product prices, improving ROI.

Customers in the Special Equipment Manufacturing Industry report smoother startups, predictable throughput, and reduced operator training time due to simple controls and consistent cake discharge. For palm kernels, the press geometry and torque delivery help achieve reliable extraction without excessive rework. Across flaxseed oil press and linseed oil press setups, users value data visibility (when paired with sensors/PLC) to monitor temperature, pressure, and yield. Over a typical payback horizon, savings often come from fewer stoppages, longer part life, and increased first-pass quality—key factors for B2B decision makers.

Sustainability & Market Trends in manufacturing

Demand for cold-pressed and specialty oils is rising, driven by clean-label trends and functional nutrition. Processors are responding by investing in efficient equipment that lowers waste, energy use, and rework. A well-designed flaxseed oil refining line or flaxseed oil refinery unit helps reduce effluent and adsorbent consumption, while precise expeller control minimizes overcooking and preserves valuable volatiles. Cake byproducts from a linseed oil expeller or black seed oil expeller can be valorized as animal feed or specialty ingredients, improving overall resource efficiency.

Hebei Huipin Machinery Co.,LTD adopts a forward-looking approach: energy-efficient drive options, sealed systems for better hygiene and air quality, and integration capabilities that support compliance with common food safety and electrical standards in target markets. As regulations tighten around emissions, noise, and workplace safety, investing in a modern flaxseed oil press or palm kernel pressing machine supports both sustainability goals and market differentiation. With scalable lines, processors can align capacity with demand, minimizing capital intensity and environmental footprint per ton produced.

Conclusion on [black seed oil expeller,flaxseed oil refinery unit,flaxseed oil refining line,flaxseed oil mill machine,flaxseed oil expeller,flaxseed oil press,linseed oil mill machine,linseed oil expeller,linseed oil press ,palm kernel pressing machine] from Hebei Huipin Machinery Co.,LTD

From black seed oil expeller lines to a complete flaxseed oil refining line, Hebei Huipin Machinery Co.,LTD delivers dependable machinery that elevates yield, quality, and uptime. Whether you need a flaxseed oil press, linseed oil expeller, linseed oil mill machine, or a palm kernel pressing machine, Huipin’s engineering and service culture help de-risk scale-up and accelerate ROI. For specifications or tailored proposals: Contact us: email: oilmakingline@gmail.com. Visit our website: https://www.oilmillchina.com.

-

Mustard Oil Extraction Machine: A Complete Guide to Industry, Technology & Future Trends

NewsNov.20,2025

-

Groundnut Oil Extraction Machine | Efficient Peanut Oil Press Solutions

NewsNov.20,2025

-

Manual Oil Press Machine: Sustainable Oil Extraction for Global Communities | Buy & Learn More

NewsNov.19,2025

-

Efficient Peanut Oil Machine Solutions for Sustainable Oil Extraction

NewsNov.19,2025

-

Essential Oil Extraction Machine: Unlocking Quality & Sustainability in Oil Production

NewsNov.18,2025

-

Latest Oil Expeller – Efficient & Sustainable Oil Extraction Machines

NewsNov.18,2025