Sep . 10, 2025 08:40 Back to list

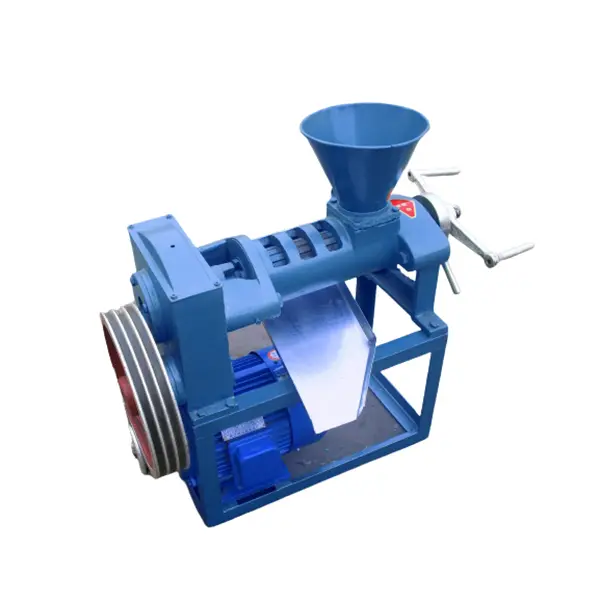

Black Seed Oil Expeller - High Yield & Quality Oil Press

Industry Trends in Oilseed Processing Equipment

The global market for oilseed processing equipment is experiencing robust growth, driven by increasing demand for natural oils in food, pharmaceutical, and cosmetic industries. Consumers are increasingly favoring cold-pressed oils due to their preserved nutritional profiles and superior flavor, which are often degraded by heat-intensive extraction methods. This shift fuels innovation in equipment like the black seed oil expeller, which is designed for efficient, low-temperature extraction.

Key trends indicate a move towards more energy-efficient, automated, and versatile machines capable of processing a diverse range of oilseeds, from traditional soy and sunflower to niche seeds like black cumin, flaxseed, and palm kernel. Manufacturers are focusing on enhancing yield rates, reducing operational costs, and ensuring the purity and quality of the extracted oil. This includes advancements in integrated systems, such as compact flaxseed oil refinery unit solutions and scalable flaxseed oil refining line equipment, which combine pressing, filtration, and even light refining within a single footprint. Furthermore, the demand for small to medium-capacity units, like the HP120 Small Capacity Cold Oil Press, is escalating, catering to artisanal producers, research labs, and small-scale industrial applications seeking to produce premium, specialty oils.

Detailed Process Flow of a Black Seed Oil Expeller

The production of black seed oil using an expeller involves a meticulously designed process to maximize oil yield and preserve the delicate properties of Nigella sativa seeds. Our machinery ensures optimal conditions throughout the entire extraction sequence.

Process Steps:

- Seed Cleaning and Preparation: Raw black cumin seeds are first subjected to thorough cleaning to remove impurities such as dust, stones, stems, and immature seeds. This typically involves vibrating screens, air classifiers, and destoners. Proper preparation is crucial for protecting the black seed oil expeller components and ensuring oil purity.

- Conditioning (Optional, for Cold Press): For cold pressing, minimal to no heat conditioning is applied. In some cases, a gentle pre-drying might occur to reduce moisture content to an optimal level (typically 6-8%) without exceeding the desired temperature threshold for cold pressing. This prevents enzymatic degradation and maintains nutritional value.

- Expelling (Cold Pressing): The cleaned and conditioned seeds are fed into the black seed oil expeller. This mechanical press, often a screw type, applies continuous pressure to the seeds. The screw shaft rotates within a barrel, gradually increasing pressure as seeds move through the press cage. This forces the oil out through small openings, while the compressed solids (oil cake) are discharged at the end. For cold pressing, the internal temperature is carefully monitored and maintained below 50°C (122°F) to prevent heat-induced degradation of delicate compounds.

- Crude Oil Filtration: The expelled crude black seed oil contains suspended solids (foots). It undergoes an initial coarse filtration step, often using a vibrating screen or settling tanks, followed by fine filtration. Plate-and-frame filters or centrifuge separators are commonly employed to remove finer particulate matter, yielding clear crude oil.

- Refining (Optional): For specific applications, further refining may be conducted. However, for premium cold-pressed black seed oil, minimal refining is preferred to retain its natural characteristics. If necessary, gentle degumming, neutralization, or deodorization might be performed, taking care to preserve the oil's integrity.

- Storage: The finished black seed oil is stored in inert container111s, typically stainless steel, in a cool, dark environment to prevent oxidation and maintain shelf life.

Product Materials and Manufacturing Processes:

- Pressing Screws and Barrels: Manufactured from high-grade alloy steel (e.g., 20CrMnTi, 38CrMoAl), selected for its exceptional hardness, wear resistance, and fatigue strength. These components undergo precision CNC machining, followed by heat treatment (carburizing and quenching) to achieve optimal surface hardness and core toughness. This ensures an extended service life even under continuous high-pressure operations.

- Main Frame and Housing: Constructed from robust carbon steel or stainless steel, fabricated through processes like welding and casting, followed by surface treatments such as powder coating or chrome plating for corrosion resistance, particularly important in demanding industrial environments like food processing or petrochemical.

- Gears and Bearings: Utilizing high-precision gears made from hardened steel and self-lubricating bearings to minimize friction and ensure smooth, quiet operation, contributing to energy efficiency.

Testing Standards and Service Life:

All our linseed oil mill machine components and assembled units adhere to stringent international quality standards, including ISO 9001 for quality management and relevant ANSI/ASME standards for mechanical design and manufacturing. Components undergo rigorous non-destructive testing (NDT), such as ultrasonic and magnetic particle inspection, to detect any material flaws. Typical service life for critical components like pressing screws exceeds 8,000 operational hours, with proper maintenance.

Target Industries and Advantages:

Our expellers serve diverse industries including food processing, pharmaceutical, cosmetic, and biofuel. In food processing, they offer energy-saving benefits through optimized motor efficiency and reduced waste. In pharmaceutical applications, the cold press method ensures the preservation of thermosensitive active compounds, leading to high-quality therapeutic oils. The robust construction provides excellent corrosion resistance, making them suitable for environments found in water supply & drainage or certain metallurgical processes where robust machinery is required.

Technical Specifications: HP120 Small Capacity Cold Oil Press

The HP120 is an exemplary flaxseed oil mill machine, designed for versatility and efficiency in small to medium-scale oil extraction. Its robust design ensures consistent performance and high-quality oil output, suitable for various specialty oils including black seed, flaxseed, and even palm kernel pressing machine operations.

| Parameter | Specification (HP120 Cold Oil Press) |

|---|---|

| Model | HP120 |

| Capacity (Black Seed) | 15-25 kg/h (varies by seed type) |

| Motor Power | 2.2 kW (3-Phase) |

| Voltage | 380V / 50Hz (Customizable) |

| Oil Extraction Rate (Black Seed) | 28-35% (up to 38% for certain varieties) |

| Residual Oil in Cake | <8% |

| Pressing Temperature | Typically < 50°C (Cold Press) |

| Material of Construction (Contact Parts) | Food-grade Stainless Steel (304/316) and High-alloy Steel |

| Dimensions (L x W x H) | Approx. 850 x 450 x 950 mm |

| Weight | Approx. 180 kg |

| Noise Level | < 70 dB |

| Control System | Manual with integrated safety features |

These specifications demonstrate the HP120's suitability for producing high-quality, cold-pressed oils. The low residual oil in cake ensures maximum economic efficiency, while the customizable voltage makes it adaptable to various global power grids.

Application Scenarios and Technical Advantages

The versatility of modern oil expellers extends across numerous applications, driven by their technical prowess and the market's demand for high-quality, unadulterated oils.

Typical Application Scenarios:

- Specialty Oil Production: Small to medium-scale enterprises producing premium oils such as black seed oil, hemp seed oil, pumpkin seed oil, and other exotic varieties for niche markets.

- Food & Beverage Industry: For direct consumption, as ingredients in dressings, marinades, or baked goods where the flavor and nutritional integrity of cold-pressed oils are highly valued.

- Pharmaceutical & Nutraceuticals: Extracting oils rich in bioactive compounds (e.g., thymoquinone from black seed oil, omega-3s from flaxseed oil) for use in supplements, capsules, or topical remedies. This demands a linseed oil expeller capable of preserving these sensitive compounds.

- Cosmetics & Personal Care: Providing virgin oils for skin care products, hair treatments, and massage oils where natural, unrefined ingredients are paramount.

- Research & Development: Universities and research institutions utilizing precision expellers for studying oilseed properties, optimizing extraction parameters, and developing new oil-based products.

- Animal Feed & Biofuel: While the primary focus is on premium oils, the oil cake byproduct can be used as high-protein animal feed, and lower-grade oils can be considered for biofuel applications, illustrating the broad utility of a flaxseed oil press.

Technical Advantages:

- High Oil Yield with Low Residual Oil: Advanced screw design and optimized press cage geometry ensure maximum oil extraction, often leaving less than 8% residual oil in the cake, which is highly competitive for a cold press.

- Preservation of Nutritional Value: The core advantage of a cold-press linseed oil press lies in its low operating temperature. This method retains heat-sensitive vitamins, antioxidants, fatty acids (e.g., Omega-3, Omega-6), and natural flavors that would otherwise be degraded by high temperatures in traditional hot pressing or chemical extraction.

- Energy Efficiency: Optimized motor and gearbox designs minimize power consumption. For instance, the HP120's 2.2 kW motor is highly efficient for its capacity, resulting in lower operational costs compared to less optimized systems.

- Robust Construction and Durability: Use of high-grade, wear-resistant alloy steels for critical components (press screws, rings) ensures a long service life and minimal downtime, even with abrasive seeds. Corrosion-resistant materials are used where oil contact occurs.

- Ease of Operation and Maintenance: Simple, intuitive controls and accessible components facilitate easy operation, cleaning, and routine maintenance, reducing labor costs and training requirements.

- Versatility: Capable of processing a wide range of oilseeds with minimal adjustments, offering flexibility for producers handling various raw materials.

- Environmentally Friendly: Mechanical extraction avoids the use of chemical solvents, making the process cleaner and the oil purer, aligning with growing ecological and health-conscious consumer preferences.

Vendor Comparison and Customized Solutions

Choosing the right oil expeller vendor requires a comprehensive evaluation beyond just initial cost. Factors such as machine performance, material quality, after-sales support, and the ability to provide customized solutions are paramount for long-term operational success.

Expeller Vendor Comparison (Illustrative):

| Feature | Our Solution (e.g., HP120) | Competitor A (Budget Option) | Competitor B (High-End Automation) |

|---|---|---|---|

| Key Material (Pressing Parts) | High-grade alloy steel (38CrMoAl), heat-treated | Carbon steel, surface hardened | Premium Stainless Steel (e.g., 316L), advanced coatings |

| Oil Extraction Rate (Black Seed) | 28-35% (excellent for cold press) | 20-28% (variable, higher residual oil) | 30-38% (optimized pre-treatment) |

| Automation Level | Manual/Semi-automatic, robust controls | Basic, manual operation | Fully automated, PLC control, remote monitoring |

| Service Life (Key Parts) | >8,000 hours | 3,000-5,000 hours | >10,000 hours |

| Maintenance Requirements | Low, accessible parts | Moderate, frequent checks | Low, predictive maintenance systems |

| Customization Options | Voltage, material (contact parts), filtration integration | Limited (voltage only) | Extensive (full system integration, bespoke design) |

| Certifications | ISO 9001, CE | Basic CE | ISO, CE, FDA-compliant materials |

Customized Solutions:

We understand that every client has unique operational requirements. Our engineering team specializes in tailoring flaxseed oil expeller systems to meet specific needs. This includes:

- Capacity Scaling: From a compact HP120 unit to larger industrial scale systems for higher throughput of black seed, flaxseed, or other oils.

- Material Selection: Offering options for food-grade stainless steel (SS304, SS316L) for all oil-contacting parts, crucial for pharmaceutical or premium food applications, ensuring FDA compliance.

- Integrated Systems: Designing and implementing complete oil pressing lines, including pre-treatment (cleaning, de-hulling), filtration (plate filters, centrifuges), and post-processing (storage tanks, bottling lines), forming a seamless flaxseed oil refining line.

- Automation and Control: Upgrading to PLC-based control systems for enhanced process monitoring, data logging, and reduced manual intervention.

- Power and Voltage Adaptations: Configuring electrical systems to meet diverse international power supply standards (e.g., 220V/60Hz, 480V/60Hz).

- Specialized Components: Custom screw designs or press cage configurations optimized for specific, challenging oilseeds, ensuring maximum yield and efficient operation.

Our commitment to ISO 9001 certified manufacturing processes ensures that all customized solutions maintain the highest standards of quality and reliability.

Application Case Studies

Our equipment has consistently delivered measurable value across various global enterprises. Here are a few examples demonstrating the impact and reliability of our oil expellers:

Case Study 1: Premium Black Seed Oil Producer, Middle East

A leading nutraceutical company in the UAE sought to expand its line of premium black seed oil supplements. They required a cold press that could guarantee minimal thermal degradation and high yield from high-value Nigella sativa seeds. We supplied a customized black seed oil expeller system, integrating the HP120 with an advanced three-stage filtration unit.

- Challenge: Maintain low processing temperatures to preserve thymoquinone content and achieve high oil purity.

- Solution: Implemented a temperature-controlled pressing environment and high-precision screw design, minimizing friction-induced heat.

- Results: Client reported a consistent thymoquinone content exceeding 1.8% (verified by HPLC analysis), exceeding their previous solvent-extracted oil. Oil yield increased by 7% compared to their older mechanical press, resulting in a 15% boost in profit margin for their flagship product within the first six months.

Case Study 2: Organic Flaxseed Oil Mill, Europe

An organic food producer in Germany aimed to launch a new line of cold-pressed organic flaxseed oil. They needed a reliable flaxseed oil expeller that complied with strict EU organic certification standards, particularly concerning material safety and process purity.

- Challenge: Achieve high extraction efficiency for flaxseed while adhering to stringent organic processing guidelines, requiring food-grade materials and no chemical contact.

- Solution: Provided a dedicated flaxseed oil press system with all oil-contacting parts constructed from certified SS316L stainless steel. The system included an automated feeding mechanism and an inline filtration unit.

- Results: The client successfully obtained organic certification for their new flaxseed oil product. The system achieved a remarkably low residual oil content of 5.5% in the press cake, which they then sold as high-protein animal feed, creating an additional revenue stream. Operational uptime has been 99% over two years, reflecting the equipment's reliability.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for an HP120 black seed oil expeller?

A1: For standard HP120 units, the lead time is generally 3-4 weeks from order confirmation and deposit. Customized solutions or larger orders may require 6-10 weeks, depending on complexity and material availability. We provide a detailed fulfillment schedule upon order confirmation.

Q2: What kind of warranty is offered with your oil expellers?

A2: We offer a standard 12-month warranty on all mechanical parts and a 6-month warranty on electrical components from the date of shipment. This covers defects in materials and workmanship under normal operating conditions. Extended warranty options are available upon request.

Q3: Do you provide installation and after-sales support?

A3: Yes, we provide comprehensive after-sales support. For smaller units like the HP120, detailed installation manuals and video guides are provided. For larger or more complex integrated systems, we offer on-site installation supervision and commissioning services by our qualified engineers. Our customer support team is available via phone and email for technical assistance, troubleshooting, and spare parts ordering, ensuring minimal downtime for your linseed oil mill machine.

Q4: Can the HP120 process different types of oilseeds?

A4: Absolutely. The HP120 is designed for versatility and can efficiently process a wide range of oilseeds, including black seed, flaxseed, hemp seed, pumpkin seed, sesame, and even smaller batches of palm kernel. Optimal settings may vary slightly for different seeds, and our technical team can provide guidance on specific seed types to ensure the best yield.

Authoritative References

- ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

- AOCS Official Methods and Recommended Practices of the AOCS. American Oil Chemists' Society.

- Gunstone, F. D. (2011). Vegetable Oils in Food Technology: Composition, Properties and Uses. Blackwell Publishing.

- United States Department of Agriculture (USDA) – Agricultural Marketing Service.

-

Mustard Oil Extraction Machine: A Complete Guide to Industry, Technology & Future Trends

NewsNov.20,2025

-

Groundnut Oil Extraction Machine | Efficient Peanut Oil Press Solutions

NewsNov.20,2025

-

Manual Oil Press Machine: Sustainable Oil Extraction for Global Communities | Buy & Learn More

NewsNov.19,2025

-

Efficient Peanut Oil Machine Solutions for Sustainable Oil Extraction

NewsNov.19,2025

-

Essential Oil Extraction Machine: Unlocking Quality & Sustainability in Oil Production

NewsNov.18,2025

-

Latest Oil Expeller – Efficient & Sustainable Oil Extraction Machines

NewsNov.18,2025