Nov . 19, 2024 17:59 Back to list

best press nut of oil press machine

The Best Press Nut of Oil Press Machines A Comprehensive Guide

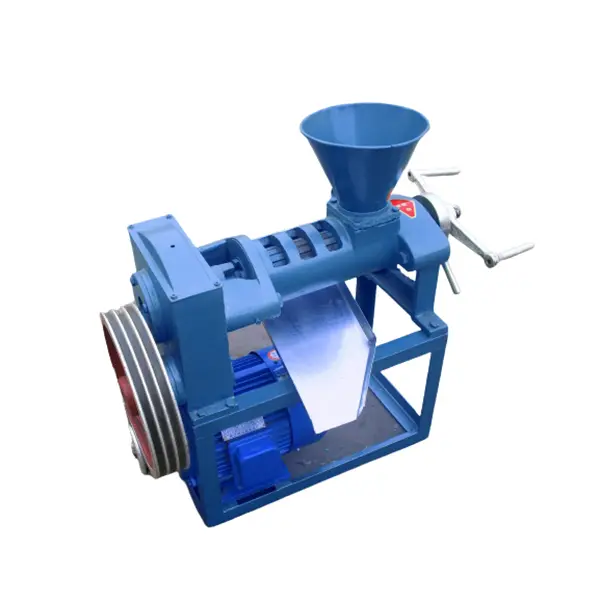

In the world of oil extraction, one cannot underestimate the significance of oil press machines. These machines have revolutionized the way we derive oils from various seeds, nuts, and vegetables. Among the numerous components of an oil press machine, the press nut stands out as one of the most crucial elements. Understanding the best press nut for oil press machines can enhance both the efficiency of oil extraction and the quality of the product.

What is a Press Nut?

A press nut, commonly known as a screw or pressing nut, is a key component in oil press machines where seeds and nuts are subjected to mechanical pressure. The function of the press nut is to convert the kinetic energy provided by the machine’s motor into pressure that crushes the material, thereby extracting oil. The design and materials used in manufacturing the press nut play a significant role in determining the machine's overall performance and efficiency.

Selection of Material

When it comes to selecting the best press nut for oil press machines, the material used is paramount. High-quality press nuts are typically made from hardened steel or stainless steel to withstand high pressure without warping or breaking. Stainless steel, in particular, offers corrosion resistance, making it ideal for the extraction process where moisture and oils might cause rust and degradation over time. The durability of the materials ensures a longer lifespan for the press nut, reducing the need for frequent replacements.

Design and Functionality

best press nut of oil press machine

The design of the press nut also contributes significantly to its efficiency. Press nuts are often designed with a helical thread, which helps to efficiently transport the seeds or nuts through the chamber while continually applying pressure. This not only aids in the extraction of oil but also helps in managing the residue left behind. The best designs allow for an optimal flow rate, reducing bottlenecks during the extraction process and leading to higher yields.

Compatibility with Various Seeds and Nuts

Another aspect to consider when selecting the best press nut is its compatibility with various seeds and nuts. Different materials have unique physical properties that require specific press nut designs for optimal extraction. For example, oilseeds such as sunflower seeds or olive pits may require a different type of press nut compared to nuts like almonds or walnuts. Therefore, it is crucial to choose a press nut that is versatile enough to accommodate multiple types of raw materials, enhancing the utility of the oil press machine.

Maintaining the Press Nut

To ensure longevity and efficiency, regular maintenance of the press nut is essential. Cleaning the press nut after each use is recommended to prevent the buildup of residues that can affect oil quality and machine performance. Additionally, periodic inspections for wear and tear can help in identifying when replacements or repairs are needed, thereby maintaining seamless operation.

Conclusion

In conclusion, the press nut is a vital component of oil press machines that significantly impacts the extraction process. When selecting the best press nut, it is important to consider the materials used, design factors, compatibility with various seeds and nuts, and the necessary maintenance protocols. Investing time and resources into choosing a high-quality press nut can result in higher oil yields and better quality oil, reflecting the importance of this small but mighty part of oil press machines. The evolution of technology continues to enhance the design and materials used in press nuts, promising even greater efficiency and reliability in oil extraction processes.

-

Oil Processing Equipment - High-Efficiency Flaking Machine

NewsJul.25,2025

-

High-Efficiency Peanut Oil Refined Machine for Quality Oil Production Leading Exporters & Companies

NewsJul.08,2025

-

High Efficiency Sunflower Seed Oil Press – Leading Cooking Oil Press Machine Factories & Suppliers

NewsJul.08,2025

-

High-Efficiency Soybean Oil Press Machine – Leading Exporters & Reliable Companies

NewsJul.07,2025

-

High-Efficiency Seed to Oil Extractor – Reliable Extraction Machinery for Your Business

NewsJul.07,2025

-

High-Quality Pressing Screw of Oil Expeller for Efficient Oil Extraction Leading Exporters & Manufacturers

NewsJul.06,2025