Aug . 16, 2024 22:32 Back to list

Analysis of China's Soybean Oil Refining Capacity and Industry Trends

The Refinement of Soybean Oil in China Trends and Insights

Soybean oil has long been a staple in the culinary traditions of many cultures, including China, where it plays an essential role in both household cooking and the food industry. As the demand for healthier oil options continues to rise, the refinement process of soybean oil in China has become a focal point of interest among manufacturers, consumers, and policymakers alike.

Understanding Soybean Oil Refinement

The refinement of soybean oil typically involves several key processes degumming, neutralization, bleaching, and deodorization. Each of these steps serves to improve the oil's quality and shelf-life, removing impurities and undesirable flavors, which is vital for consumer acceptance and product safety. In China, a significant volume of soybean oil is refined to enhance its appeal in both domestic and international markets.

China's Growing Demand for Soybean Oil

China is one of the largest consumers of soybean oil in the world, driven by its massive population and changing dietary patterns. With rising health consciousness, consumers have shifted towards oils perceived as healthier alternatives, such as soybean oil, which is rich in polyunsaturated fats. The increased popularity of cooking shows and international cuisine has also contributed to this trend, with more households opting for premium-quality oils.

The Chinese government has also taken steps to promote soybean cultivation and oil processing to achieve greater food security and reduce reliance on imported oils

. This has led to significant investments in refining facilities, technological advancements, and the incorporation of sustainable practices in the production chain.Technological Advancements in Refinement Processes

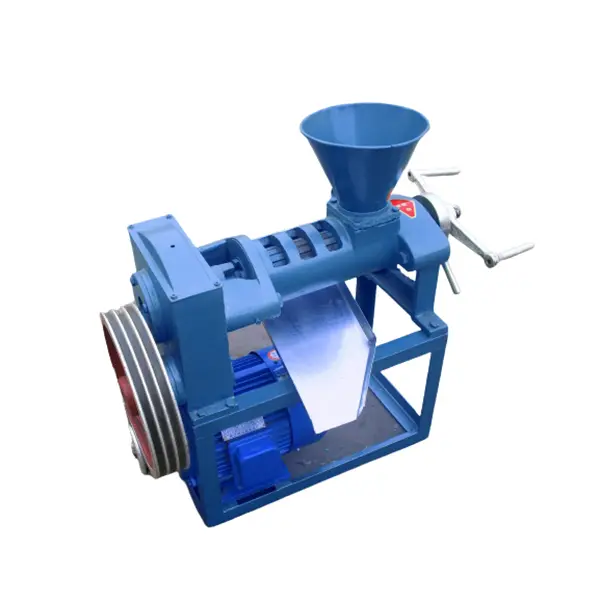

china soybean oil refined unit

As the soybean oil market evolves, so too does the technology used in its refinement. Modern refining processes in China have seen the incorporation of high-efficiency equipment that enhances oil yield and minimizes waste. For instance, advancements in enzymatic degumming and cold pressing techniques have made it possible to produce high-quality oils while preserving their natural flavors and nutrients.

Moreover, automation and digitalization in oil refining plants have contributed to improved consistency in quality and efficiency. These technologies enable better monitoring and control of the production process, ensuring that the final product meets the stringent standards of both domestic and international markets.

Challenges Faced by the Industry

Despite the growth and improvements in soybean oil refinement, the industry still faces several challenges. Fluctuations in soybean prices, driven by global market conditions, can significantly impact the cost of production. Additionally, environmental concerns related to oil extraction and refining processes have prompted the industry to adopt more sustainable practices, which can be costly.

Quality control is another crucial concern, as varying quality of raw materials can lead to inconsistencies in the final product. The Chinese government has implemented strict regulations and quality assurance measures to address these issues, ensuring that refined soybean oil meets safety and quality standards.

Conclusion

The refinement of soybean oil in China represents a dynamic sector of the food processing industry, characterized by innovation, demand, and regulatory challenges. With the continuous evolution of consumer preferences and technological advancements, the industry is poised for further growth. As awareness around health and sustainability continues to shape the market, the future of refined soybean oil in China looks promising. It will be essential for producers to adapt to these changes, ensuring that they not only meet the demands of consumers but also contribute positively to the environment and economy.

-

HP 120 Model Cold Oil Press-Hebei Huipin Machinery|Energy Efficiency, Multi-Functionality

NewsAug.18,2025

-

HP 120 Model Cold Oil Press-Hebei Huipin Machinery|Oil Extraction, Multi-Functional

NewsAug.18,2025

-

HP 120 Cold Oil Press - Hebei Huipin | Automation & Efficiency

NewsAug.18,2025

-

Safflower Oil Press Service: Efficient & Quality Extraction

NewsAug.18,2025

-

HP 120 Cold Oil Press-Hebei Huipin Machinery|Oil Extraction, High Efficiency

NewsAug.17,2025

-

HP 120 Cold Oil Press - Hebei Huipin Machinery | High-Efficiency Oil Extraction

NewsAug.17,2025