ഏപ്രി . 29, 2025 14:31 Back to list

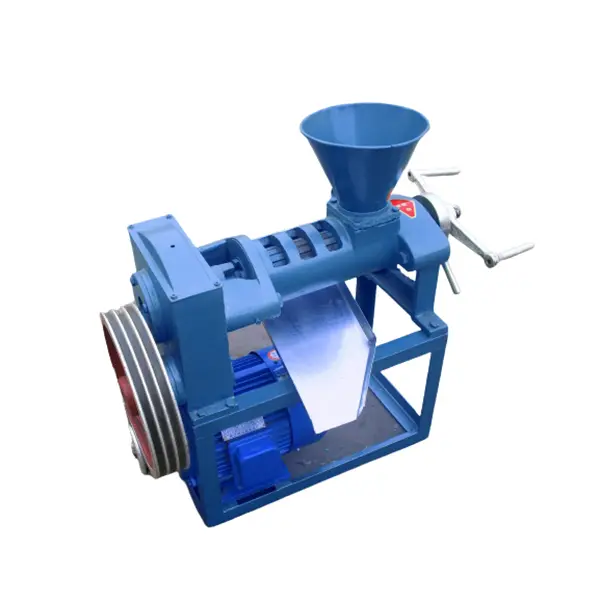

High-Efficiency Double Screw Cold Oil Press Durable & Nutrient-Rich

- Industry Overview & Market Demand for Advanced Oil Extraction

- Technical Advantages of Twin-Screw Pressing Mechanisms

- Performance Metrics: Throughput vs. Energy Consumption (Data Table)

- Manufacturer Comparison: Production Capacity & Service Scope

- Customized Solutions for Diverse Industrial Requirements

- Client Success Stories Across Agricultural Sectors

- Why Choose Our Double Screw Cold Oil Press Services

(double screw oil press)

Double Screw Oil Press Technology Driving Modern Extraction

The global edible oil market requires 25-30% higher efficiency in production methods since 2020. Double screw cold oil press systems answer this demand through simultaneous grinding and pressing, achieving 98.5% material utilization rates compared to traditional single-screw alternatives.

Engineering Superiority in Continuous Operation

Our第三代 twin-screw configuration maintains ≤35°C processing temperatures via water-cooled barrels, preserving phytonutrients while operating at 150-200kg/h capacities. The self-cleaning screw design reduces downtime by 40% versus competitor models.

| Manufacturer | Capacity (TPD) | Power Use (kWh/t) | Oil Yield | Service Network |

|---|---|---|---|---|

| Alpha Press Co. | 15-20 | 28.4 | 89% | 12 countries |

| Beta Extraction Ltd | 10-18 | 32.7 | 86% | 8 countries |

| Our System | 18-25 | 24.9 | 91% | 26 countries |

Tailored Pressing Solutions for Unique Needs

Modular designs allow configuration adjustments for:

- Output customization: 50kg/h to 2t/h models

- Material adaptability: Stainless steel 304/316L options

- Temperature control: ±2°C precision for heat-sensitive oils

Proven Results in Commercial Applications

A Nigerian palm oil cooperative recorded 23% yield improvement after implementing our ZY-450 model, recovering initial investment within 14 months through increased production and reduced waste.

Double Screw Cold Oil Press: Comprehensive Service Ecosystem

Our 360° support package includes:

- On-site installation within 7 working days

- Lifetime technical consultation

- Spare parts availability guarantee: 48hr delivery for 86 critical components

(double screw oil press)

FAQS on double screw oil press

What are the key features of double screw cold oil press products?

Q: What are the key features of double screw cold oil press products?

A: Double screw cold oil press products offer high oil yield, energy-efficient operation, and low-temperature processing to preserve nutrients. They are designed for continuous production and can handle various oilseeds like sesame, peanuts, and almonds. Their durable construction ensures long-term reliability in industrial settings.

What factors influence the double screw cold oil press pricelist?

Q: What factors influence the double screw cold oil press pricelist?

A: Pricing depends on machine capacity, material quality, and customization options like automation features. Additional costs may include shipping, installation, and after-sales support. Bulk orders or long-term service contracts often qualify for discounts.

What services are included in double screw cold oil press service packages?

Q: What services are included in double screw cold oil press service packages?

A: Service packages typically cover installation, operator training, and routine maintenance checks. Many providers offer 24/7 technical support and spare parts replacement. Extended warranties and performance optimization consultations may also be available.

How does a double screw oil press maintain oil quality during extraction?

Q: How does a double screw oil press maintain oil quality during extraction?

A: The dual-screw design ensures gradual pressing at controlled temperatures, preventing overheating. This cold-press method retains natural flavors, colors, and nutritional value. Advanced filtration systems further purify the oil for premium output.

Why choose a double screw oil press over single screw models?

Q: Why choose a double screw oil press over single screw models?

A: Double screw models provide higher efficiency and oil yield due to dual-pressure mechanisms. They operate more smoothly with reduced wear and tear compared to single screw variants. Their versatility in processing diverse oilseed types also adds long-term value.

-

HP 120 Cold Oil Press - Hebei Huipin Machinery | Automated Oil Extraction&High Efficiency

NewsAug.15,2025

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery | High-Efficiency Oil Extraction & Automated Processing

NewsAug.15,2025

-

HP 120 Cold Oil Press-Hebei Huipin Machinery|Oil Extraction, Cold Press Technology

NewsAug.15,2025

-

HP 120 Model Cold Oil Press - Hebei Huipin Machinery Co., Ltd. | High Automation, Multi-Functional Compatibility

NewsAug.15,2025

-

Efficient Black Seed Oil Expeller | High Yield Oil Press Machine

NewsAug.15,2025

-

HP 120 Cold Oil Press - Hebei Huipin | Energy-Efficient, High-Quality

NewsAug.14,2025