ພ.ຈ. . 12, 2024 09:26 Back to list

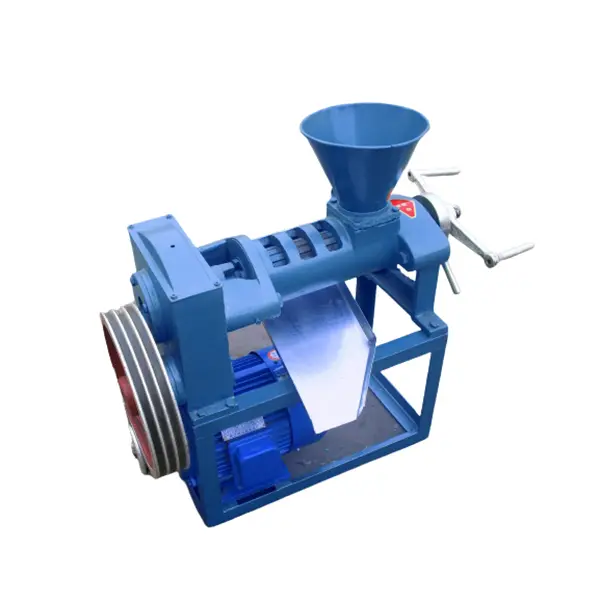

soybean oil refining machine company

The Importance of Soybean Oil Refining Machines in Modern Industry

In the landscape of the edible oil sector, soybean oil stands out as one of the most widely produced and consumed oils globally. To meet the increasing demand for high-quality soybean oil, the refining process plays a crucial role, making soybean oil refining machines essential for manufacturers. This article explores the significance of soybean oil refining machines, their features, advantages, and the impact they have on the industry.

Understanding Soybean Oil Refining

Soybean oil is extracted from the seeds of the soybean plant and is valued for its health benefits and versatility in cooking. However, crude soybean oil must undergo refining to remove impurities, free fatty acids, and other undesirable components before it becomes suitable for consumption. The refining process typically involves several stages, including degumming, neutralization, bleaching, and deodorization. Each of these steps requires specific machinery designed to handle the unique properties of soybean oil.

The Role of Soybean Oil Refining Machines

Soybean oil refining machines are specialized equipment that streamline and automate the various stages of the refining process. Their primary functions include

1. Degumming This initial step removes phospholipids and other impurities from crude soybean oil using water or acid. Degumming machines are designed to introduce these additives efficiently, ensuring that unwanted substances are separated effectively.

2. Neutralization This process involves the neutralization of free fatty acids, which can affect the flavor and stability of the oil. Neutralization machines usually employ caustic soda to achieve the desired acidity levels.

3. Bleaching The bleaching stage eliminates color pigments and other impurities that affect the oil's appearance. Bleaching machines utilize adsorbents, such as clay or activated carbon, to absorb these pigments.

4. Deodorization This crucial step removes any remaining volatile compounds that impart off-flavors or odors. Deodorization machines employ steam distillation under vacuum conditions to achieve a neutral odor and flavor profile.

5. Cooling and Storage After refining, the oil must be cooled and stored properly to maintain its quality. Sophisticated cooling and storage tanks with temperature control features are essential components of soybean oil refining facilities.

soybean oil refining machine company

Advantages of Using Soybean Oil Refining Machines

Investing in soybean oil refining machines comes with numerous benefits

- Efficiency Modern refining machines are designed for high efficiency, which means that they can process large quantities of oil in a shorter amount of time. This increased throughput is critical for meeting market demand.

- Quality Control Automated refining systems provide consistent and high-quality output. With the precise control of operating parameters, manufacturers can minimize the variability that often accompanies manual processes.

- Cost-Effectiveness Although the initial investment in soybean oil refining machines may be substantial, the long-term savings in labor, energy, and waste management can offset these costs. Increased efficiency also translates to a higher yield of refined oil.

- Sustainability Many modern refining machines are designed with eco-friendly technologies, which help minimize waste production and energy consumption. This focus on sustainability is not only beneficial for the environment but can also enhance the brand image of manufacturers.

- Adaptability Advanced refining technology allows manufacturers to adjust processes to cater to different needs, including producing specialty oils or catering to specific market requirements.

The Future of Soybean Oil Refining

As global health trends begin to favor soybean oil for its nutritional benefits—such as being a source of polyunsaturated fatty acids—demand for refined soybean oil is expected to grow. Consequently, the soybean oil refining machine market will continue to expand as manufacturers seek innovative ways to enhance their production capabilities and maintain quality standards.

Conclusion

In conclusion, soybean oil refining machines are an indispensable part of the edible oil industry. They facilitate the production of high-quality soybean oil that meets consumer expectations and health standards. As technology advances and the market evolves, the importance of these machines will only increase, ensuring that soybean oil remains a staple in kitchens around the world. Investing in the right refining technology is paramount for any manufacturer looking to thrive in this competitive landscape.

-

LZY-206 Double Screw Cold Oil Press – Maximize Yield, Preserve Nutrients

NewsAug.21,2025

-

Efficient Black Seed Oil Expeller & Multi-Seed Oil Press

NewsAug.19,2025

-

HP 120 Model Cold Oil Press-Hebei Huipin Machinery|Energy Efficiency, Multi-Functionality

NewsAug.18,2025

-

HP 120 Model Cold Oil Press-Hebei Huipin Machinery|Oil Extraction, Multi-Functional

NewsAug.18,2025

-

HP 120 Cold Oil Press - Hebei Huipin | Automation & Efficiency

NewsAug.18,2025

-

Safflower Oil Press Service: Efficient & Quality Extraction

NewsAug.18,2025