11월 . 04, 2024 22:58 Back to list

best oil mill spare parts

The Importance of Quality Spare Parts in Oil Mill Operations

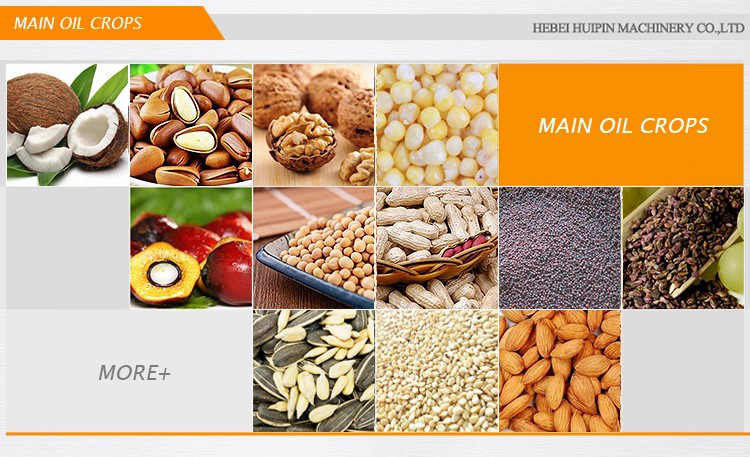

In the world of oil milling, the efficiency and effectiveness of operations significantly hinge on the quality of spare parts used. An oil mill, designed to extract oil from various seeds and nuts, is a complex machinery system that requires precise components to function optimally. Investing in the best oil mill spare parts is not merely a practice; it is an essential strategy for businesses aiming to enhance productivity and minimize downtime.

Quality spare parts play a vital role in ensuring the smooth operations of oil mills. They are essential for the maintenance and repair of critical machinery components such as crushers, screw presses, and filters. High-quality parts are engineered to withstand the demands of continuous use and extreme operating conditions. These parts typically exhibit superior durability, which reduces the frequency of breakdowns and extends the overall lifespan of the machinery.

When mills use substandard spare parts, they risk facing several challenges. Lower-quality components can lead to inefficient operations, increased energy consumption, and, ultimately, higher production costs. Furthermore, these parts may not fit correctly or perform as expected, resulting in additional repairs and a cascade of operational delays. The implications of downtime due to equipment failure can be significant, often leading to financial losses and reduced output.

best oil mill spare parts

Another crucial factor to consider is the sourcing of spare parts. Reputable suppliers or manufacturers specializing in oil mill components offer a wide range of options tailored to specific machinery models. These suppliers ensure that their products meet high industry standards, thereby providing reliability and efficiency. Moreover, partnerships with experienced suppliers allow mills to stay updated on the latest innovations and technologies in spare parts, helping them to optimize their operations further.

In addition to quality and reliable supply, businesses should also prioritize implementing a proactive maintenance approach. Regular inspections and timely replacements of worn-out parts can prevent larger issues from arising. A well-maintained oil mill operates at peak performance, leading to higher oil extraction rates and overall better product quality.

In conclusion, the significance of using the best oil mill spare parts cannot be overstated. They are fundamental to achieving operational efficiency, reducing costs, and ensuring the longevity of the oil milling process. As the industry continues to evolve, staying ahead with quality spare parts and proactive maintenance practices will ensure that oil mills remain competitive and profitable in an ever-changing market. By safeguarding the heart of their operations, businesses can achieve their goals and contribute positively to the agricultural and food processing sectors.

-

Sunflower Oil Seed Press Machine - High Efficiency, Durable & Cost-effective Extraction

NewsJun.24,2025

-

High-Efficiency Physical Oil Refining Unit - Leading Exporters & Trusted Companies

NewsJun.10,2025

-

High-Efficiency Animal Oil Refining Machine - Leading Exporters & Reliable Companies

NewsJun.10,2025

-

Camellia Oil Mill Machine for Efficient Oil Extraction Leading Exporters & Companies

NewsJun.10,2025

-

Premium Pressing Shaft for Oil Press Machines Exporters

NewsJun.10,2025

-

High-Efficiency Centrifugal Filters Durable Industrial Separation

NewsJun.10,2025