Dec . 22, 2024 15:10 Back to list

spiral oil expeller factories

The Role of Spiral Oil Expeller Factories in the Oil Industry

In recent years, the demand for edible oil has surged enormously, driven by population growth, rising living standards, and an expanding food industry. As a result, oil extraction technology has advanced significantly, with spiral oil expellers becoming increasingly integral in the production process. Spiral oil expeller factories are at the forefront of this transformation, providing efficient and cost-effective solutions for oil extraction.

Understanding Spiral Oil Expellers

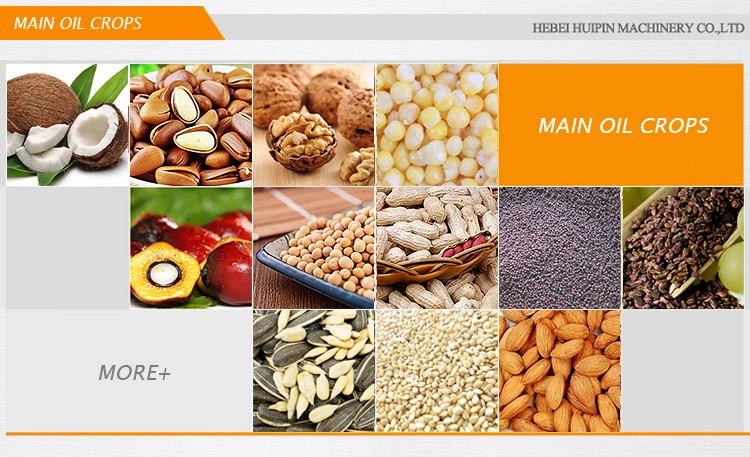

Spiral oil expellers are machines designed to extract oil from seeds and nuts. These machines utilize a mechanical pressing technique that involves a spiral screw within a cylindrical chamber. As the seeds are fed into the chamber, the screw rotates and compresses them, facilitating oil extraction through mechanical force. This type of expeller is favored for its efficiency and ability to handle a variety of oilseeds, including sunflower seeds, soybeans, peanuts, and more.

Importance in the Industry

Spiral oil expeller factories play a crucial role in the global oil market. They contribute to various sectors, including food production, pharmaceuticals, and biodiesel. The factory's capacity to produce high quantities of oil quickly makes them valuable assets in meeting both local and international demand. Moreover, the oil produced can be utilized for cooking, salad dressings, and as an ingredient in processed foods.

Additionally, the efficiency of spiral oil expellers contributes to sustainability. They often require less energy compared to traditional extraction methods, reducing the carbon footprint associated with oil production. Their design also allows for the recovery of oil from a wide range of raw materials, maximizing resource utilization.

Innovation and Technology

spiral oil expeller factories

As technology advances, spiral oil expeller factories are increasingly incorporating automation and digital controls into their operations. Modern expellers are equipped with features such as temperature control, automatic feeding systems, and enhanced energy efficiency settings, resulting in increased productivity and reduced waste. The integration of data analytics helps optimize the oil extraction process, allowing factories to monitor performance in real-time and make necessary adjustments to enhance efficacy.

Moreover, research and development are pivotal in improving the design and functionality of spiral oil expellers. Manufacturers are constantly looking for ways to improve recovery rates, reduce wear and tear on equipment, and enhance overall longevity. Innovations such as improved materials and coatings for the screw and chamber have led to longer-lasting machines that require less maintenance.

Economic Impact

Spiral oil expeller factories also have a significant economic impact. They create numerous jobs in manufacturing, maintenance, and logistics. Furthermore, as these factories enable the efficient extraction of oil, they contribute to the local economy by providing raw materials necessary for food production and other industries.

Additionally, these factories can foster entrepreneurship. By setting up small-scale oil extraction units, they empower local farmers and entrepreneurs to generate income from the crops they grow. This not only enhances food security but also promotes agricultural development in rural areas.

Conclusion

In conclusion, spiral oil expeller factories are a cornerstone of the oil extraction industry. Their ability to efficiently and sustainably produce oil from various seeds positions them as vital players in meeting the growing global demand for edible oils. As technology continues to evolve, these factories will likely become even more sophisticated, contributing to economic development and sustainability. The future of the oil industry hinges on the efficiency and innovation brought forth by these spiral oil expeller factories, making them an essential component of modern agriculture and food production.

-

Food Oil Refined Unit Companies: Leading Manufacturers & Exporters

NewsAug.23,2025

-

Expert Oil Filter Machine Service & Solutions | Quality & Reliability

NewsAug.22,2025

-

LZY-206 Double Screw Cold Oil Press – Maximize Yield, Preserve Nutrients

NewsAug.21,2025

-

Efficient Black Seed Oil Expeller & Multi-Seed Oil Press

NewsAug.19,2025

-

HP 120 Model Cold Oil Press-Hebei Huipin Machinery|Energy Efficiency, Multi-Functionality

NewsAug.18,2025

-

HP 120 Model Cold Oil Press-Hebei Huipin Machinery|Oil Extraction, Multi-Functional

NewsAug.18,2025