jan . 17, 2025 00:50 Back to list

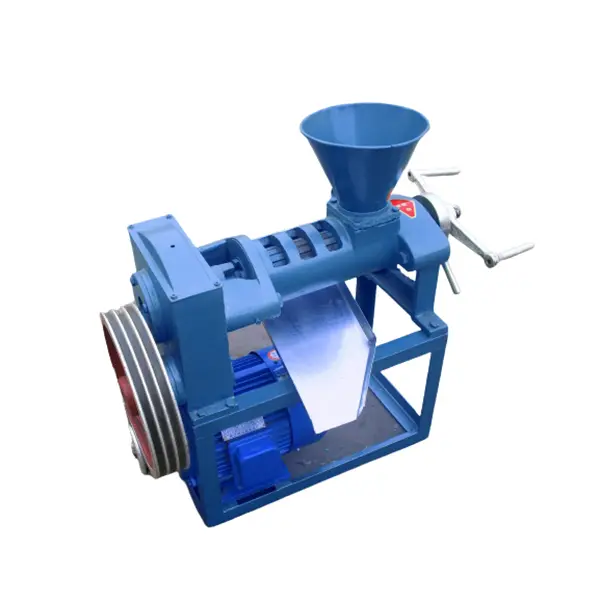

press nut of oil press machine

The press nut of an oil press machine plays a crucial role in the efficiency and effectiveness of oil extraction. It acts as a pivotal component that assists in the pressing and extraction process, ensuring that the machine operates smoothly and yields high-quality oil. Understanding the intricacies and functionalities of the press nut is key to optimizing the performance of your oil press machine.

Authoritative sources in the field of mechanical engineering emphasize the importance of using original manufacturer parts when replacing the press nut. Authentic press nuts are specifically designed to fit the original specifications of the machine, ensuring optimal performance. Using generic or substandard replacements can result in mechanical failures and decreased efficiency in oil extraction, leading to increased operational costs and lower-quality oil. Trustworthiness in the performance and reliability of an oil press machine begins with investing in quality components like the press nut. Users of oil press machines, from small-scale producers to large industrial operations, benefit from a focus on high-caliber components. These components not only ensure consistent and efficient oil production but also enhance the reputation of the oil producer by delivering a premium product to the market. In conclusion, the press nut of an oil press machine, though a small component, has a substantial impact on the machine’s overall functionality and the quality of the oil produced. It requires attention to detail in its design and manufacturing, regular maintenance to prevent operational issues, and a commitment to using high-quality, authentic parts. By understanding and appreciating the critical role of the press nut, operators can optimize the performance of their oil press machines, ensuring reliable and efficient oil production. This knowledge enhances not only the operation of the machinery but also solidifies the operator's reputation as a producer of high-quality oil.

Authoritative sources in the field of mechanical engineering emphasize the importance of using original manufacturer parts when replacing the press nut. Authentic press nuts are specifically designed to fit the original specifications of the machine, ensuring optimal performance. Using generic or substandard replacements can result in mechanical failures and decreased efficiency in oil extraction, leading to increased operational costs and lower-quality oil. Trustworthiness in the performance and reliability of an oil press machine begins with investing in quality components like the press nut. Users of oil press machines, from small-scale producers to large industrial operations, benefit from a focus on high-caliber components. These components not only ensure consistent and efficient oil production but also enhance the reputation of the oil producer by delivering a premium product to the market. In conclusion, the press nut of an oil press machine, though a small component, has a substantial impact on the machine’s overall functionality and the quality of the oil produced. It requires attention to detail in its design and manufacturing, regular maintenance to prevent operational issues, and a commitment to using high-quality, authentic parts. By understanding and appreciating the critical role of the press nut, operators can optimize the performance of their oil press machines, ensuring reliable and efficient oil production. This knowledge enhances not only the operation of the machinery but also solidifies the operator's reputation as a producer of high-quality oil.

Latest news

-

High-Efficiency Oil Seed Press Line Trusted Exporters & Leading Companies

NewsJul.04,2025

-

Continuous Horizontal Vacuum Belt Filter - Reliable Filtration Solutions for Industrial Needs

NewsJul.04,2025

-

Sunflower Oil Seed Press Machine - High Efficiency, Durable & Cost-effective Extraction

NewsJun.24,2025

-

High-Efficiency Physical Oil Refining Unit - Leading Exporters & Trusted Companies

NewsJun.10,2025

-

High-Efficiency Animal Oil Refining Machine - Leading Exporters & Reliable Companies

NewsJun.10,2025

-

Camellia Oil Mill Machine for Efficient Oil Extraction Leading Exporters & Companies

NewsJun.10,2025