Nov . 06, 2024 16:21 Back to list

Refined Vegetable Oil Processing Equipment for Efficient Production Solutions

The Evolution of Vegetable Oil Refining Machinery

In recent years, the demand for vegetable oils has surged due to the growing awareness of health benefits associated with plant-based oils compared to animal fats. This rising demand has led to significant advancements in the technology and machinery used for refining vegetable oils. Companies specializing in vegetable oil refining machinery are at the forefront of this evolution, providing essential tools to meet the needs of the food industry and beyond.

Vegetable oil refining is a crucial process that transforms crude vegetable oils into refined oils, ready for consumption or further processing

. The refining process involves several key steps degumming, neutralization, bleaching, and deodorization. Each of these steps is vital for ensuring the final product meets the required quality standards, including taste, color, and shelf stability.1. Degumming The first step in vegetable oil refining involves the removal of phospholipids and other impurities. Modern degumming machines utilize advanced technologies, such as centrifugation and enzymatic treatments, to effectively remove these unwanted components. Companies are now focusing on developing more efficient degumming processes that consume less water and energy, making them environmentally friendly.

2. Neutralization Following degumming, neutralization removes free fatty acids to improve the oil's flavor and stability. This process traditionally involved chemical neutralization with sodium hydroxide, but many companies are exploring alternatives that minimize chemical use and enhance safety in the production process. Some advanced machines allow for a continuous neutralization process, increasing efficiency and reducing downtime.

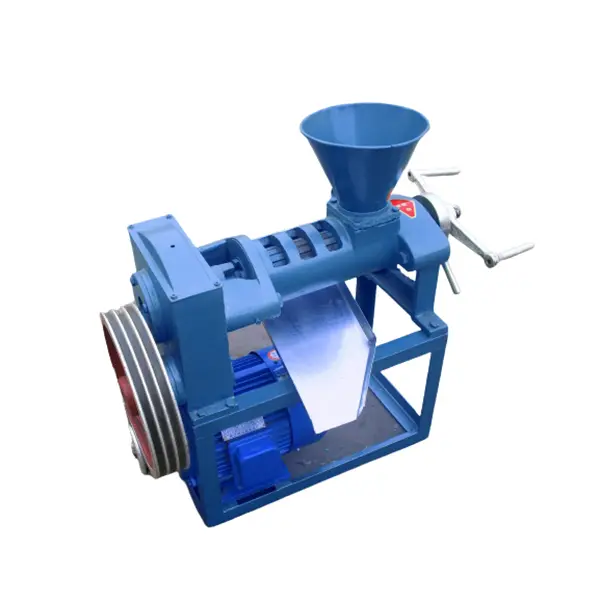

vegetable oil refined machine company

3. Bleaching The bleaching process removes color pigments and other impurities using adsorbents like activated clay or carbon. Innovative machines are being introduced that combine bleaching and deodorizing processes, significantly reducing the time and space needed for refining operations. These modern systems use precise temperature and pressure controls to ensure optimal results while minimizing energy consumption.

4. Deodorization The final step in the refining process is deodorization, which eliminates undesirable odors and flavors. Traditional deodorization methods can be energy-intensive; however, new technological developments have led to the creation of machines that operate under vacuum conditions, using less heat and energy while achieving desired results. This not only boosts the quality of the oil but also enhances the overall process efficiency.

The rise of automation and smart technology in the vegetable oil refining sector cannot be overlooked. Companies are incorporating IoT (Internet of Things) solutions in their machines, allowing for real-time monitoring and control of the refining processes. This development leads to improved accuracy, reduced waste, and enhanced productivity. Additionally, predictive maintenance technologies help prevent downtime by predicting equipment failures before they occur.

Moreover, sustainability has become a key focus in the vegetable oil refining industry. Companies are investing in eco-friendly technologies to reduce waste and lower emissions. The use of renewable energy sources in the refining processes and initiatives to recycle by-products are becoming increasingly common, aligning with global efforts towards sustainable practices.

In conclusion, the vegetable oil refining machinery sector is undergoing a significant transformation driven by technological advancements and changing consumer preferences. As the demand for high-quality vegetable oils continues to grow, companies specializing in refining machinery are pushing the boundaries of innovation. Through efficient processes, sustainable practices, and the integration of intelligent technologies, the future of vegetable oil refining holds great promise, ensuring that both producers and consumers benefit from healthier and more environmentally friendly oils.

-

Crude Sunflower Oil Refining Machine Efficient Processing & Services

NewsMay.16,2025

-

Premium Oil Mill Spare Parts Exporters Durable & Custom Solutions

NewsMay.16,2025

-

High-Efficiency Vegetable Oil Refined Units Export-Quality Solutions

NewsMay.15,2025

-

Premium Small Oil Press Machine Exporters Compact & Efficient Design

NewsMay.15,2025

-

Commercial Oil Press Machines High Efficiency & Cost-Effective Solutions

NewsMay.14,2025

-

High-Efficiency Groundnut Oil Machines Trusted Factories & Suppliers

NewsMay.14,2025