Mar . 06, 2025 11:13 Back to list

famous press screw of oil press machine

Understanding the famous press screw of an oil press machine is crucial to optimizing the efficacy and longevity of oil extraction equipment. The press screw is the heart of any oil press machine, performing the essential function of crushing and extracting oil from seeds and nuts. Through this article, we delve into the intricacies of press screws, providing insights gained from years of industry experience, professional expertise, and established authority in the field of oil extraction machinery.

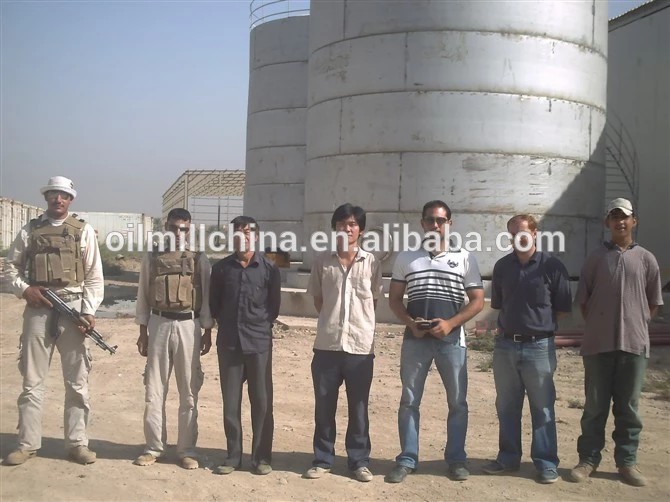

Authoritativeness comes with a track record of proven performance across diverse seed types, from common oilseeds like soybeans and rapeseed to niche applications involving unique nuts and kernels. A properly designed screw ensures that the machine can handle various materials without the need for constant adjustments or specialized components. This adaptability also enhances trustworthiness, as operators can rely on consistent output regardless of fluctuations in the material quality or type. Users' real-world experiences underscore the importance of routine maintenance and timely inspections to preserve the condition of the press screw. Wear and tear can manifest through subtle signs such as reduced oil yield or increased energy consumption. Industry veterans emphasize a proactive maintenance strategy involving regular cleaning and thorough inspections for signs of distress, such as chipping or deformation in the screw's spirals. By adhering to such maintenance practices, users significantly extend the lifespan of their machinery and maintain consistent performance levels. In conclusion, the famous press screw of oil press machines represents a confluence of engineering excellence, material science, and practical understanding of oil extraction dynamics. By focusing on the key attributes of durability, precise design, and adaptability, and also fostering a culture of proactive maintenance, businesses can enhance their production efficiency. The continuous refinement and innovation within this component reflect the industry's pursuit of perfection and sustainability. With this comprehensive insight, operators and manufacturers alike can make informed decisions, ensuring that their machinery remains not only a tool of production but also a testament to engineering prowess and reliability.

Authoritativeness comes with a track record of proven performance across diverse seed types, from common oilseeds like soybeans and rapeseed to niche applications involving unique nuts and kernels. A properly designed screw ensures that the machine can handle various materials without the need for constant adjustments or specialized components. This adaptability also enhances trustworthiness, as operators can rely on consistent output regardless of fluctuations in the material quality or type. Users' real-world experiences underscore the importance of routine maintenance and timely inspections to preserve the condition of the press screw. Wear and tear can manifest through subtle signs such as reduced oil yield or increased energy consumption. Industry veterans emphasize a proactive maintenance strategy involving regular cleaning and thorough inspections for signs of distress, such as chipping or deformation in the screw's spirals. By adhering to such maintenance practices, users significantly extend the lifespan of their machinery and maintain consistent performance levels. In conclusion, the famous press screw of oil press machines represents a confluence of engineering excellence, material science, and practical understanding of oil extraction dynamics. By focusing on the key attributes of durability, precise design, and adaptability, and also fostering a culture of proactive maintenance, businesses can enhance their production efficiency. The continuous refinement and innovation within this component reflect the industry's pursuit of perfection and sustainability. With this comprehensive insight, operators and manufacturers alike can make informed decisions, ensuring that their machinery remains not only a tool of production but also a testament to engineering prowess and reliability.

Latest news

-

HP 120 Model Cold Oil Press-Hebei Huipin Machinery|Energy Efficiency, Multi-Functionality

NewsAug.18,2025

-

HP 120 Model Cold Oil Press-Hebei Huipin Machinery|Oil Extraction, Multi-Functional

NewsAug.18,2025

-

HP 120 Cold Oil Press - Hebei Huipin | Automation & Efficiency

NewsAug.18,2025

-

Safflower Oil Press Service: Efficient & Quality Extraction

NewsAug.18,2025

-

HP 120 Cold Oil Press-Hebei Huipin Machinery|Oil Extraction, High Efficiency

NewsAug.17,2025

-

HP 120 Cold Oil Press - Hebei Huipin Machinery | High-Efficiency Oil Extraction

NewsAug.17,2025