Oct . 07, 2024 09:21 Back to list

odm edible oil production line

ODM Edible Oil Production Line Innovations in Oil Manufacturing

The demand for edible oils continues to surge globally due to population growth and changing dietary habits. To meet this increasing demand efficiently, many manufacturers are turning to ODM (Original Design Manufacturer) solutions for their edible oil production lines. ODM offers a unique approach that not only enhances production capabilities but also improves product quality and safety.

Understanding ODM in Edible Oil Production

An ODM edible oil production line involves a manufacturing process where an external partner designs and produces complex oil processing systems tailored to specific requirements. This relationship allows companies to focus on their core competencies while significantly reducing development costs and time. By leveraging the expertise of ODM manufacturers, businesses can access cutting-edge technology and innovation without the need to invest heavily in research and development.

Key Components of an ODM Edible Oil Production Line

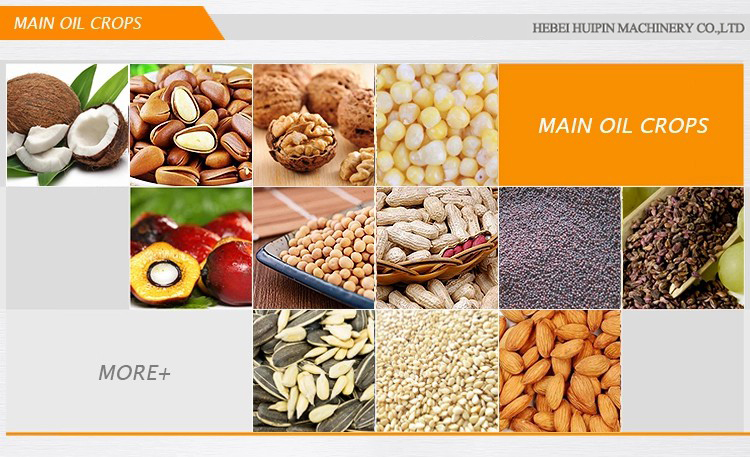

1. Seed Preparation The production line begins with the preparation of seeds, which undergo cleaning, drying, and dehulling. This step is crucial for ensuring that impurities are removed, and the seeds are ready for oil extraction.

2. Oil Extraction The extraction process can employ either mechanical pressing or solvent extraction methods. Mechanical pressing is favored for its efficiency and lower energy consumption, while solvent extraction provides a higher yield and is often utilized for larger-scale operations. ODM partners often provide advanced extraction technologies that improve oil yield and quality.

3. Refining Process Once extracted, crude oil must undergo refining to remove undesirable impurities, including free fatty acids, phospholipids, and color pigments. An ODM production line typically integrates sophisticated refining equipment that employs neutralization, bleaching, and deodorization processes, ensuring a high-quality final product that meets market standards.

4. Quality Control Quality assurance is paramount in edible oil production. ODM manufacturers implement rigorous testing and monitoring systems throughout the production line, ensuring that the oil meets safety and quality regulations. This includes testing for contaminants, fatty acid profiles, and oxidation levels.

odm edible oil production line

5. Packaging The final stage involves packaging the refined oil in user-friendly containers. ODM solutions can include automated packaging lines that enhance efficiency and maintain product integrity until it reaches the consumer.

Advantages of Using ODM Solutions

1. Customization ODM partners work closely with clients to design production lines that specific needs and preferences, allowing for customization of processes, machinery, and even branding.

2. Cost-Effectiveness By outsourcing production line design and manufacturing, businesses can significantly reduce overall operational costs while maintaining high-quality production standards.

3. Scalability As market demands change, an ODM edible oil production line can be easily scaled up or down, allowing companies to remain agile and responsive to consumer needs.

4. Access to Cutting-Edge Technology ODM manufacturers often stay ahead of industry trends and innovations, meaning clients can benefit from the latest advancements without having to invest directly in R&D.

Conclusion

As the edible oil market continues to expand, adopting ODM solutions for production lines offers a strategic advantage for manufacturers. By leveraging specialized expertise, companies can enhance efficiency, improve product quality, and ultimately drive greater consumer satisfaction. With the right ODM partnership, the future of edible oil production looks promising and innovative.

-

Sunflower Oil Seed Press Machine - High Efficiency, Durable & Cost-effective Extraction

NewsJun.24,2025

-

High-Efficiency Physical Oil Refining Unit - Leading Exporters & Trusted Companies

NewsJun.10,2025

-

High-Efficiency Animal Oil Refining Machine - Leading Exporters & Reliable Companies

NewsJun.10,2025

-

Camellia Oil Mill Machine for Efficient Oil Extraction Leading Exporters & Companies

NewsJun.10,2025

-

Premium Pressing Shaft for Oil Press Machines Exporters

NewsJun.10,2025

-

High-Efficiency Centrifugal Filters Durable Industrial Separation

NewsJun.10,2025