Oct . 08, 2024 15:30 Back to list

Efficiency and Versatility of Plate and Frame Filter Press in Industrial Applications

Understanding the ODM Plate-and-Frame Filter Press A Key Tool in Filtration Technology

In various industrial applications, effective separation of solids from liquids is crucial for maintaining quality and ensuring compliance with regulatory standards. One popular device that excels in this function is the plate-and-frame filter press, particularly the ODM (Open Door Model) variant. This equipment is favored for its efficiency, versatility, and ease of operation.

Understanding the ODM Plate-and-Frame Filter Press A Key Tool in Filtration Technology

One of the standout features of the ODM plate-and-frame filter press is its design, which allows for easy access and maintenance. The open-door configuration means that operators can quickly remove the filter cloths and clean the chambers without needing to disassemble the entire unit. This accessibility significantly reduces downtime, contributing to higher operational efficiency and lower maintenance costs.

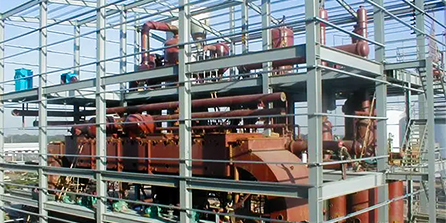

odm plate-and frame filter press

The filtration process in a plate-and-frame filter press is highly efficient due to the large surface area provided by the plates. Each plate can be fitted with filter cloths that determine the particle size of the solid being separated. This adaptability makes the ODM filter press suitable for a variety of materials and applications. Whether dealing with fine particulates in a chemical slurry or larger solids in food processing, the press can be configured to meet specific filtration needs.

Moreover, ODM filter presses come with various features to enhance their performance. Many models include automatic plate shifters, which facilitate the opening and closing of the plates for easier cleaning and maintenance. Additionally, advancements in filter press technology have led to the integration of automation systems that monitor the filtration process, providing real-time data on pressure levels and flow rates. This data can be invaluable for optimizing the filtration process and ensuring consistent output quality.

The environmental impact of filtration processes can also be mitigated with the use of plate-and-frame filter presses. By efficiently separating solids from liquids, these devices aid in the recovery of valuable materials and reduce the quantity of waste that requires disposal. In industries striving for sustainability, the ability to reclaim resources while minimizing environmental footprint is a significant advantage.

In conclusion, the ODM plate-and-frame filter press is an essential piece of equipment in the realm of industrial filtration. Its efficient design, ease of maintenance, and adaptability to various applications make it a preferred choice for many industries. As businesses continue to prioritize efficiency and sustainability, the role of advanced filtration technologies like the ODM filter press will only grow, leading to clearer liquids and better resource management in the industrial landscape.

-

LZY-206 Twin-Screw Cold Press: Efficient Oil Extraction

NewsAug.04,2025

-

Professional Safflower Oil Press Service | AI-Efficient

NewsAug.03,2025

-

HP290 First Press Oil Expeller Machinery: Efficient Oil Extraction

NewsAug.02,2025

-

Top Food Oil Refined Unit Companies w/ GPT-4 Turbo Tech

NewsAug.01,2025

-

Premium Black Seed Oil Expeller - High Efficiency Cold Press Oil Machine

NewsJul.31,2025

-

Oil Processing Equipment - High-Efficiency Flaking Machine

NewsJul.25,2025