nov. . 18, 2024 21:53 Back to list

Essential Components and Spare Parts for Oil Mill Machinery and Equipment

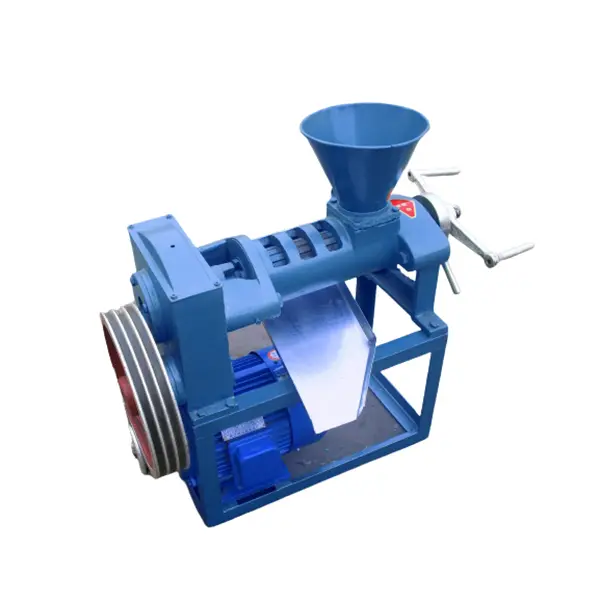

Understanding Oil Mill Spare Parts Essential Components for Optimal Performance

The oil milling industry is a crucial sector that plays a vital role in food production and various industries. Oil mills are used to extract oil from seeds, nuts, and other materials, producing essential oils needed for cooking, industrial applications, and cosmetics. Like any mechanical operation, oil mills require regular maintenance and replacement of spare parts to function optimally. In this article, we will dive into the world of oil mill spare parts, understanding their importance, types, and how they contribute to the efficiency of milling operations.

The Importance of Spare Parts

Oil mills operate in challenging environments characterized by high temperatures, constant motion, and heavy loads. Over time, components can wear out or become damaged, leading to decreased efficiency, increased downtime, and higher operational costs. Regular maintenance and timely replacement of spare parts help in minimizing production interruptions and extending the lifespan of milling equipment.

Having access to quality spare parts is vital for maintaining the productivity and reliability of oil mills. When machines are equipped with original or high-quality spare parts, they are more likely to operate at maximum efficiency, ensuring a consistent output of oil. Furthermore, using inferior or incompatible parts can lead not only to equipment failure but also to safety risks for the operators.

Types of Oil Mill Spare Parts

1. Gearing and Drive Components The gear systems in an oil mill are vital for transferring power and torque from the motor to the milling machinery. Spare parts such as gears, bearings, and pulleys are essential for smooth operations. Regular replacement of worn gears is crucial to avoid breakdowns.

2. Pressing Equipment The oil extraction process often involves extraction presses, which are subjected to high pressure and wear. Key spare parts in this category include pressing screws, plates, and cake discharge systems. Upkeep of these components ensures efficient oil recovery and minimizes residue waste.

3. Seals and Gaskets Seals and gaskets prevent oil leaks and maintain the integrity of the system. Regular inspection and replacement of these parts help in maintaining operational efficiency and preventing contamination of the oil, thus preserving its quality.

oil mill spare parts products

4. Heating Systems Oil extraction processes often involve heat. Heating elements and temperature sensors need to be maintained carefully. Spare parts such as heaters, thermal regulators, and safety valves are crucial for maintaining the appropriate temperature during the extraction process.

5. Electrical Components The electrical systems in oil mills control various operations, from machine start-up to monitoring efficiency. Spare parts like motors, control panels, and wiring are essential for ensuring that electrical components operate without fail.

6. Filters and Separation Equipment Filtration systems are important for ensuring the purity of the extracted oil. Elements such as filter bags, mesh screens, and separators require periodic replacement to maintain oil quality and equipment effectiveness.

Choosing the Right Spare Parts

When selecting spare parts for oil mills, several considerations come into play. Quality and compatibility are paramount; always opt for parts from reputable manufacturers to ensure performance and safety. It is also essential to maintain an inventory of critical spare parts to minimize downtime in case replacements are needed unexpectedly.

Working with suppliers who understand the specific needs of oil milling operations can greatly enhance efficiency. Suppliers should offer parts that adhere to industry standards and regulations, ensuring reliability and performance.

Conclusion

Oil mill spare parts are the backbone of efficient oil extraction and milling operations. Understanding the importance and types of spare parts ensures that oil mills can maintain productivity while minimizing costs associated with unplanned downtimes. As the industry continues to evolve with advancements in technology, choosing high-quality spare parts will remain essential for mill operators looking to optimize their operations. In a competitive market, investing in the right spare parts not only contributes to efficiency but also enhances the overall quality of the oil produced, benefiting both producers and consumers alike.

-

Efficient Plate Frame Filter Press for Oil & Gas Exporters & Companies

NewsMay.19,2025

-

High-Efficiency Palm Oil Press Machine Exporters & Manufacturers

NewsMay.19,2025

-

Centrifuges & Separators Equipment Exporters High-Efficiency Solutions

NewsMay.18,2025

-

Premium Cottonseed Oil Refined Machines Export-Quality & Efficient

NewsMay.18,2025

-

Premium Black Seed Oil Expellers & Refining Machines Exporters

NewsMay.18,2025

-

Premium Rapeseed Oil Plants Reliable Exporters & Manufacturers

NewsMay.17,2025