снеж . 10, 2024 16:11 Back to list

Edible Oil Filtration Solutions from Leading Manufacturing Facilities Across the Industry

The Importance of Edible Oil Filter Factories in Modern Food Production

In the realm of food production, the quality and safety of edible oils are paramount. As consumers become more health-conscious, the demand for high-quality edible oils continues to rise. This creates an increasing need for efficient and reliable edible oil filtration processes. Herein lies the significance of edible oil filter factories, which play a crucial role in ensuring that the oils we consume are not only safe but also retain their nutritional value.

Understanding Edible Oil Filtration

Edible oil filtration is a critical step in the production of oils, removing impurities, sediments, and micro-particles that may affect both flavor and quality. This process is essential not just for enhancing the visual appeal of the oil, but also for prolonging shelf life and meeting health standards. The filtration methods vary, ranging from simple mechanical filters to advanced technologies like membrane filtration and centrifugal separation.

The role of edible oil filter factories is to provide robust equipment and solutions that facilitate these filtration processes. These factories are equipped with state-of-the-art machinery and employ sophisticated technologies to ensure that the oil purification process meets the high standards required by the food industry.

The Manufacturing Process

The manufacturing process within an edible oil filter factory encompasses various stages, including the design, production, and quality testing of filtration equipment. Factories typically produce a wide range of oil filters, including cartridge filters, bag filters, and crossflow filters, each designed to cater to specific types of oils and production capacities.

The design phase starts with understanding the unique requirements of clients, whether they are small-scale producers or large industrial manufacturers. Engineers in these factories utilize computer-aided design (CAD) software to create detailed blueprints for the filtration equipment, ensuring that every aspect meets operational needs.

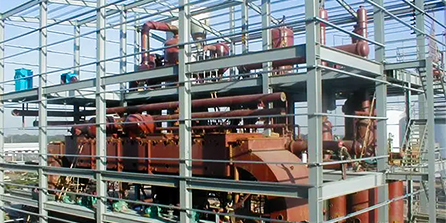

edible oil filter factory

Once the designs are finalized, the manufacturing phase begins. Factories utilize high-quality materials, such as stainless steel, which is resistant to corrosion and can withstand the high temperatures involved in oil processing. Each piece of equipment is meticulously crafted, and rigorous quality control measures are implemented to guarantee that the final products comply with international safety and quality standards.

Challenges and Innovations

Despite the advancements in edible oil filtration technologies, edible oil filter factories face several challenges. One of the most significant issues is the ever-evolving regulations regarding food safety and quality. Producers must stay updated with the latest compliance requirements, which can vary from country to country.

Innovation also plays a pivotal role in overcoming these challenges. Many factories are now integrating smart technology and automation into their manufacturing processes. This allows for enhanced precision in filtration and reduces the margin for human error. Furthermore, the use of IoT (Internet of Things) technologies enables real-time monitoring of filtration processes, helping producers optimize efficiency and reduce waste.

Additionally, environmental sustainability has become a pressing concern in recent years. Edible oil filter factories are responding by adopting eco-friendly practices, such as using recycled materials for filters and implementing energy-efficient production methods. This not only helps in reducing the carbon footprint but also appeals to environmentally conscious consumers.

Conclusion

In conclusion, edible oil filter factories are integral to the food production industry, playing a vital role in producing high-quality edible oils. With the growing demand for healthier food options and increasing regulations on food safety, these factories are more important than ever. Through continuous innovation and commitment to quality, they ensure that the oils reaching consumers' tables are safe, nutritious, and desirable.

As the industry evolves, it is essential for edible oil filter factories to adapt to new technologies and sustainability practices, ensuring their operations are as efficient and environmentally friendly as possible. By doing so, they not only contribute to the health of consumers but also to the protection of the planet, fostering a brighter future for the edible oil sector.

-

LZY-206 Twin-Screw Cold Press: Efficient Oil Extraction

NewsAug.04,2025

-

Professional Safflower Oil Press Service | AI-Efficient

NewsAug.03,2025

-

HP290 First Press Oil Expeller Machinery: Efficient Oil Extraction

NewsAug.02,2025

-

Top Food Oil Refined Unit Companies w/ GPT-4 Turbo Tech

NewsAug.01,2025

-

Premium Black Seed Oil Expeller - High Efficiency Cold Press Oil Machine

NewsJul.31,2025

-

Oil Processing Equipment - High-Efficiency Flaking Machine

NewsJul.25,2025