Okt . 13, 2024 03:02 Back to list

custom food oil refining machine

Custom Food Oil Refining Machines The Key to High-Quality Edible Oils

In the modern food industry, the demand for high-quality edible oils is ever-increasing. This necessity has led to the development of custom food oil refining machines, designed to meet specific needs while ensuring optimal product quality. These machines play an essential role in the oil production process, refining crude oils into the safe, palatable, and nutritious options that consumers seek today.

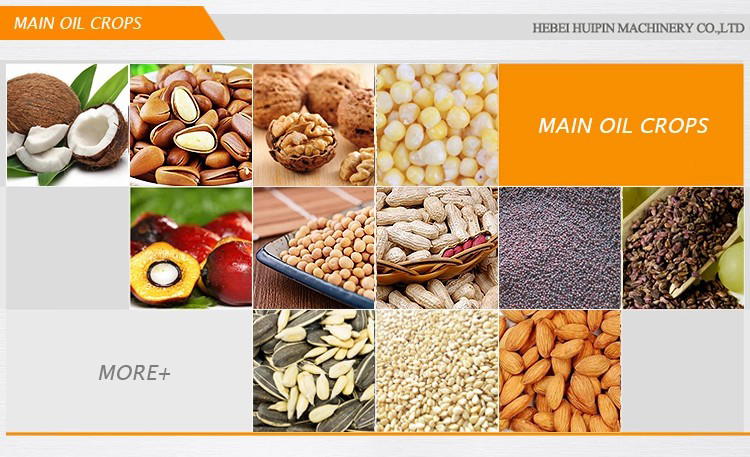

Custom food oil refining machines offer flexibility and precision, catering to the unique requirements of various oil types, including vegetable, sunflower, palm, and olive oil. Each type of oil has distinct characteristics that demand tailored refining processes. For instance, the refining method for palm oil will differ significantly from that used for olive oil due to variations in fatty acid composition, color, and odor. Custom machines can be calibrated to address these differences, optimizing the refining process to yield the best possible product.

The refining process generally involves several stages degumming, neutralization, bleaching, and deodorization. Each stage plays a crucial role in enhancing the quality of the final product. Degumming removes phospholipids and other impurities, while neutralization eliminates free fatty acids. Bleaching removes pigments that can affect the color and clarity of the oil, and deodorization eradicates any undesirable smells or flavors. Custom refining machines can be designed to carry out these processes efficiently, ensuring minimal loss of valuable nutrients while maximizing the yield of high-quality oil.

custom food oil refining machine

Moreover, sustainability is becoming an increasingly important factor in the food industry. Custom food oil refining machines can be designed with energy efficiency in mind, utilizing advanced technologies that reduce waste and energy consumption. This focus on sustainability not only helps companies to lower their operational costs but also meets the growing consumer demand for environmentally friendly products. By integrating features like heat recovery systems and environmentally safe detergents, manufacturers can produce oil in a way that aligns with global ecological standards.

Investing in a custom food oil refining machine also empowers businesses to gain a competitive edge

. With the ability to produce tailored products, companies can cater to niche markets and differentiate themselves from competitors. For example, a business specializing in organic oils can utilize a machine that adheres strictly to organic processing standards, thus appealing to health-conscious consumers.Furthermore, these machines often come with advanced control systems that allow operators to monitor and adjust parameters in real-time, ensuring consistent product quality. Automation and technology integration streamline the refining process, reducing labor costs and minimizing human error.

In conclusion, custom food oil refining machines are transforming the edible oil industry by ensuring high-quality products tailored to specific needs. Their versatility, efficiency, and sustainability focus make them indispensable for businesses looking to thrive in a competitive marketplace. As consumers continue to demand better, healthier, and more environmentally friendly options, the technological advancements in custom refining machinery will play a pivotal role in shaping the future of edible oil production. Companies willing to invest in such innovations will not only enhance their product quality but also commit to sustainable practices that benefit both the environment and the consumer.

-

Premium Black Seed Oil Expeller - High Efficiency Cold Press Oil Machine

NewsJul.31,2025

-

Oil Processing Equipment - High-Efficiency Flaking Machine

NewsJul.25,2025

-

High-Efficiency Peanut Oil Refined Machine for Quality Oil Production Leading Exporters & Companies

NewsJul.08,2025

-

High Efficiency Sunflower Seed Oil Press – Leading Cooking Oil Press Machine Factories & Suppliers

NewsJul.08,2025

-

High-Efficiency Soybean Oil Press Machine – Leading Exporters & Reliable Companies

NewsJul.07,2025

-

High-Efficiency Seed to Oil Extractor – Reliable Extraction Machinery for Your Business

NewsJul.07,2025